Grid point making method for lenticular screen three-dimensional printed chart

A technology of three-dimensional printing and lenticular lenticular, which is applied in the printing field and can solve problems such as unsuitable lenticular lenticular stereograms, reduced image clarity and three-dimensionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

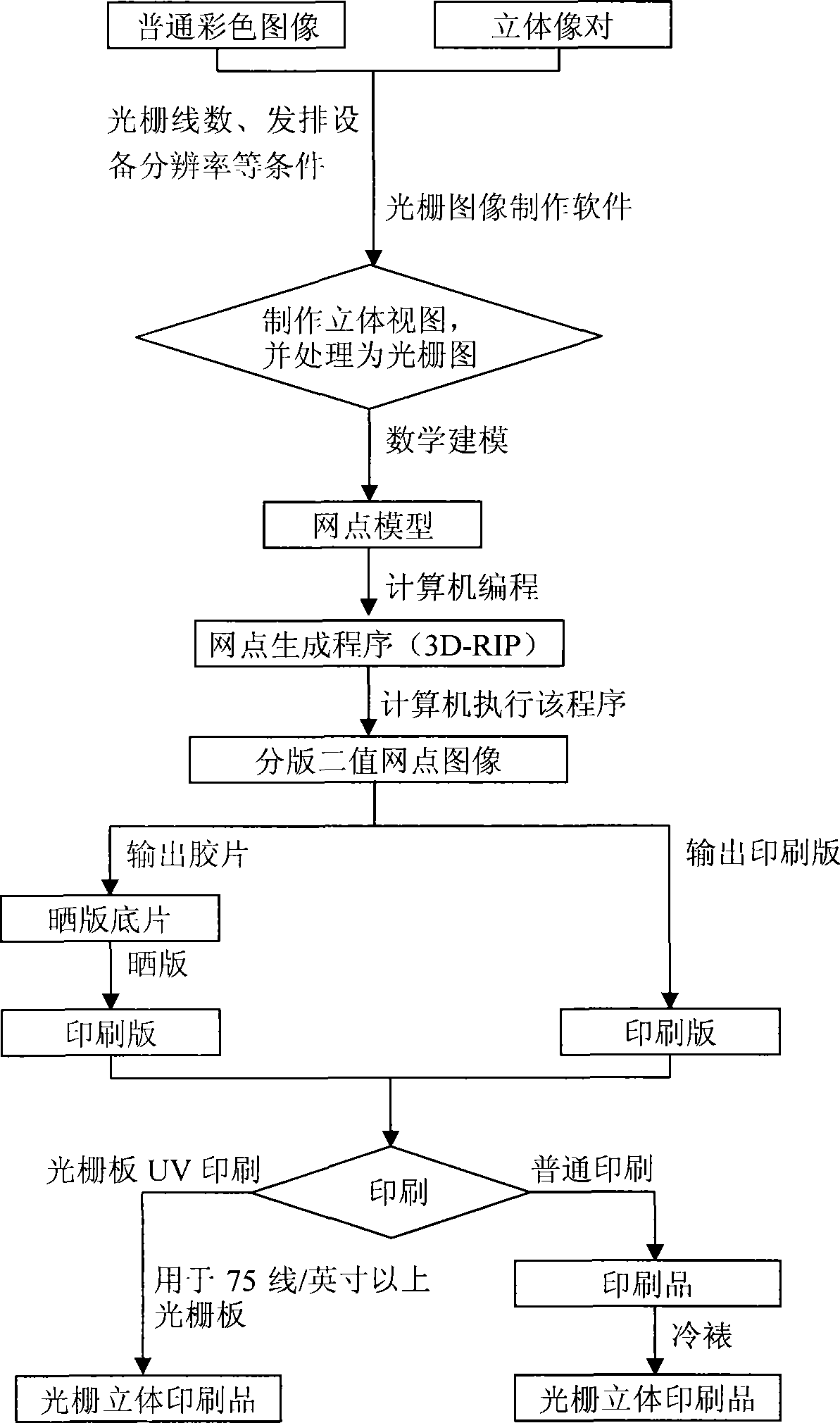

Method used

Image

Examples

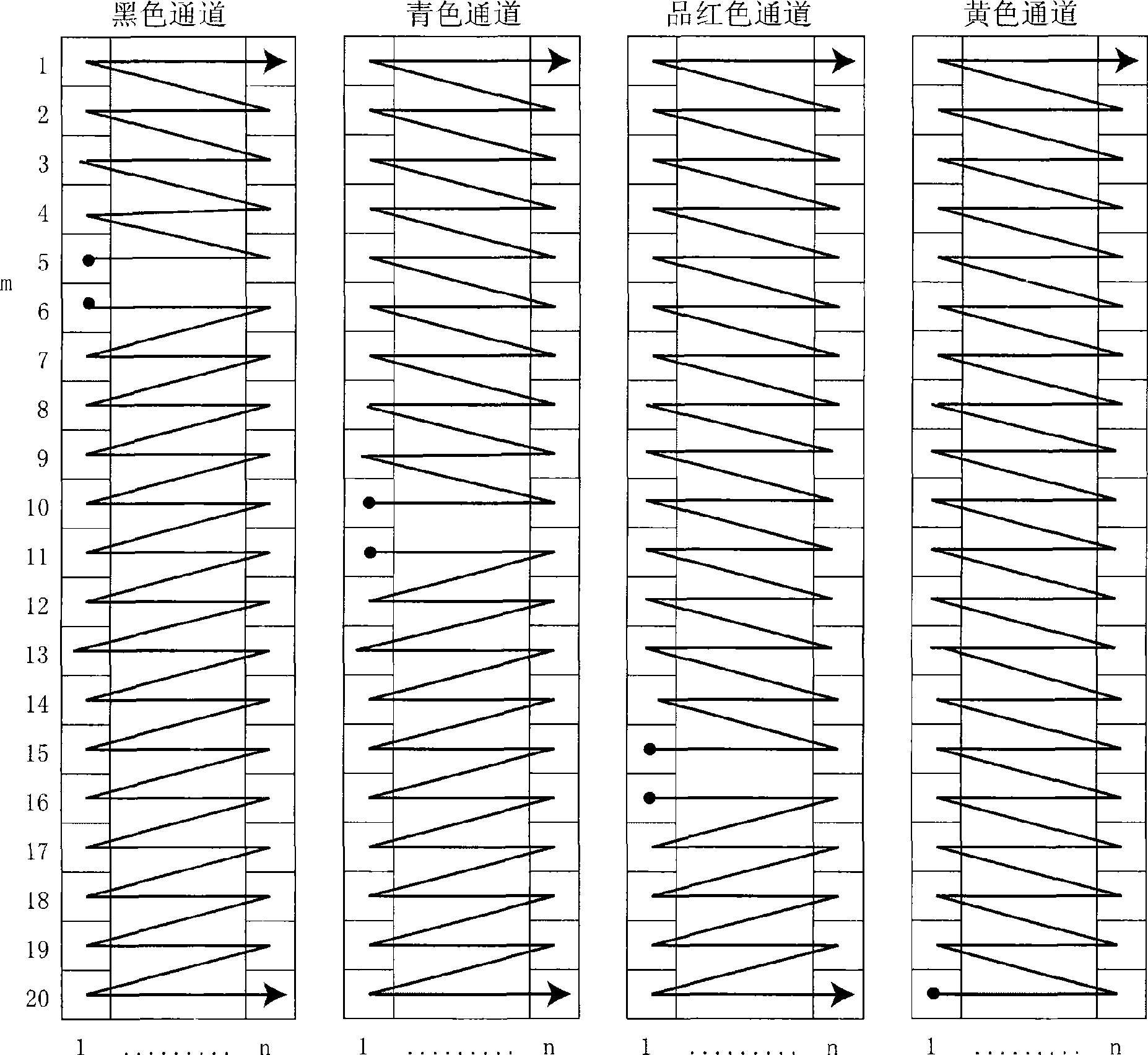

Embodiment 1

[0048] (1), with 70 lines / inch grating, direct plate making with 2400 dots / inch resolution on Heidelberg TopSetter102 direct plate-making machine, adopt formula (1), obtain:

[0049] a · n ≈ 2400 70

[0050] a·n≈34

[0051] a ≈ 34 n ,

[0052] From the above calculations, we can see that:

[0053] With 70 lines / inch grating and 2400 dots / inch output device output, when each view generates 1 row of laser dots (n=1), the number of stereoscopic views required to be produced is 34; when each view generates 2 rows of laser When point (n=2), the number of stereoscopic views required to make is 17, in the present embodiment, get n=2;

[0054] (2), the outlet model is carried out mathematical modeling, the establishment method is:

[0055] (1) Determine the size of the dot unit

[0056] 1) According to the calculation fo...

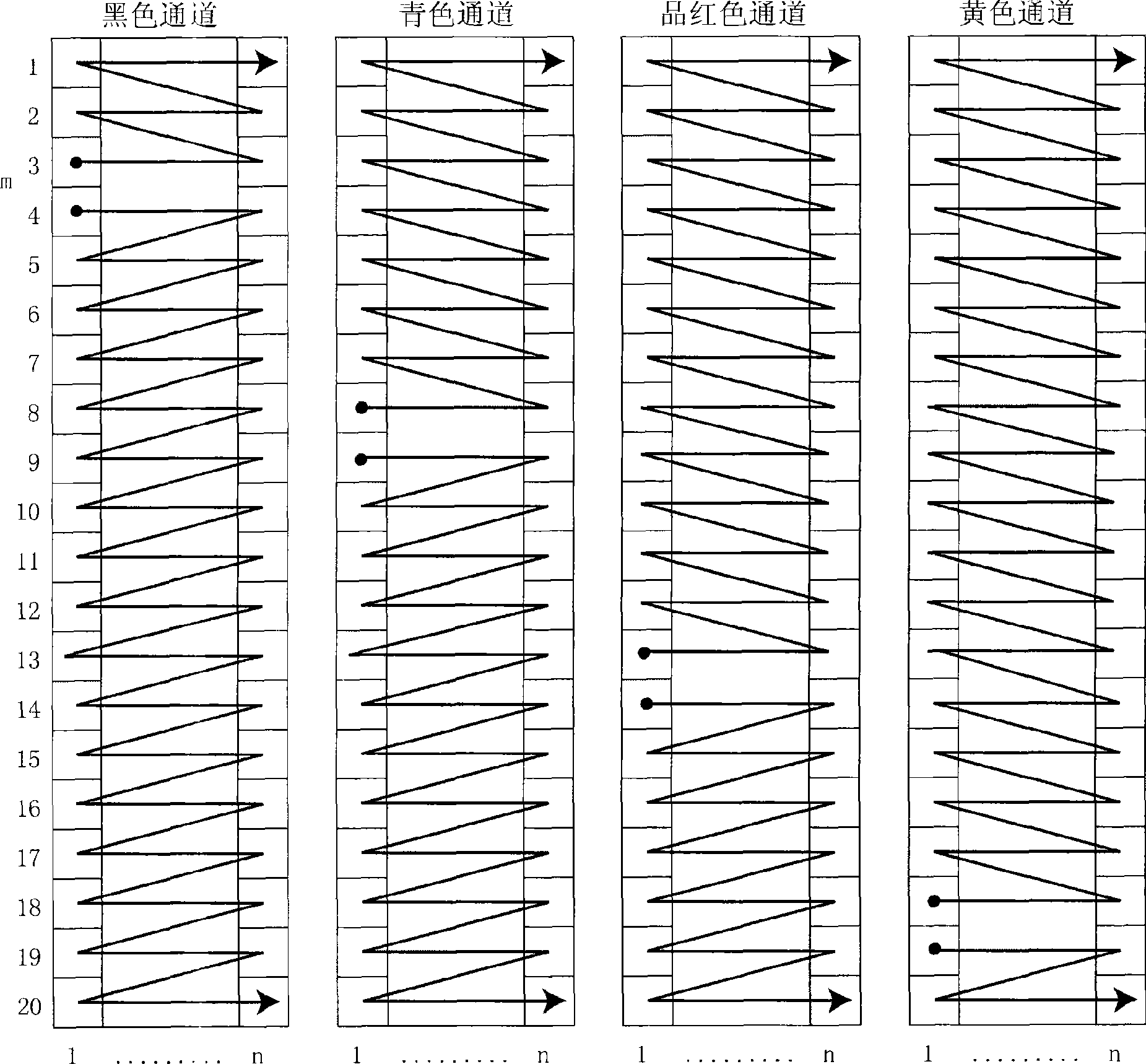

Embodiment 2

[0085] (1), with 75 lines / inch grating, direct plate making with 2400 points / inch resolution on the Heidelberg TopSetter102 direct plate-making machine, adopt formula (1), obtain:

[0086] a · n = 2400 75

[0087] a·n=34

[0088] a = 34 n ,

[0089] From the above calculations, we can see that:

[0090] With 75 lines / inch grating and 2400 dots / inch output device output, when each view generates 4 rows of laser points (n=4), the number of stereoscopic views required to be made is 8;

[0091] (2), the outlet model is carried out mathematical modeling, the establishment method is:

[0092] (1) Determine the size of the dot unit

[0093] 1) According to the calculation formula of the human eye's ability to distinguish objects, determine the height of the dot unit;

[0094] From formula (2):

[0095] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com