Airplane covering transversal stretch forming loading track designing and numerical control code generating method

A technology of loading trajectory and aircraft skin, applied in the direction of digital control, computer control, program control, etc., can solve the problems of restricting the overall level of aircraft manufacturing, lack of precision control function of CNC drawing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

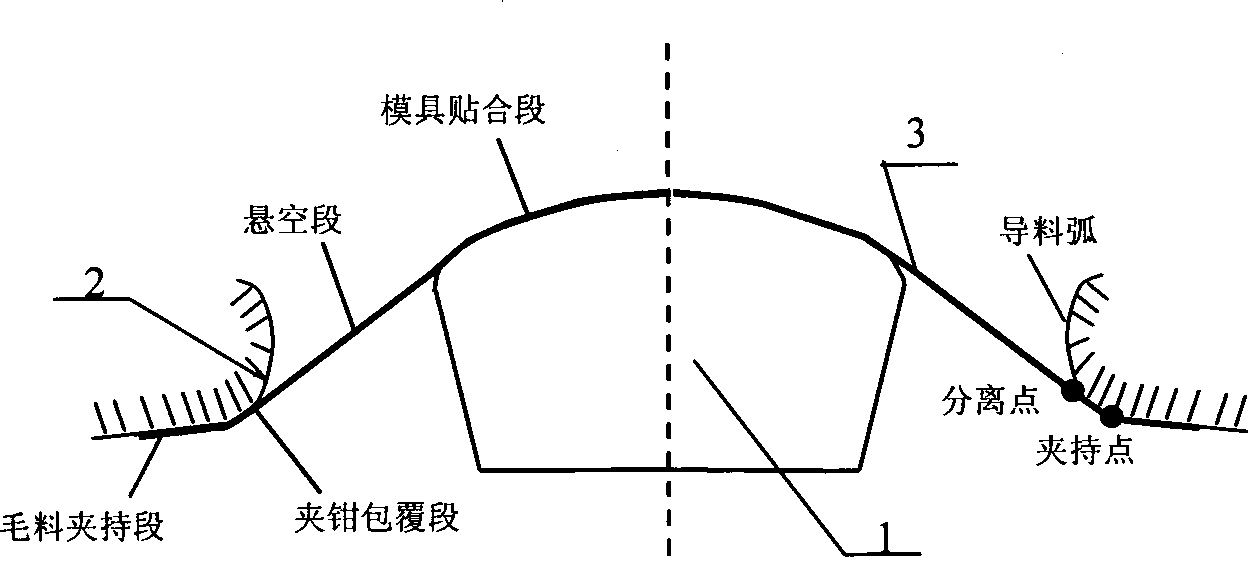

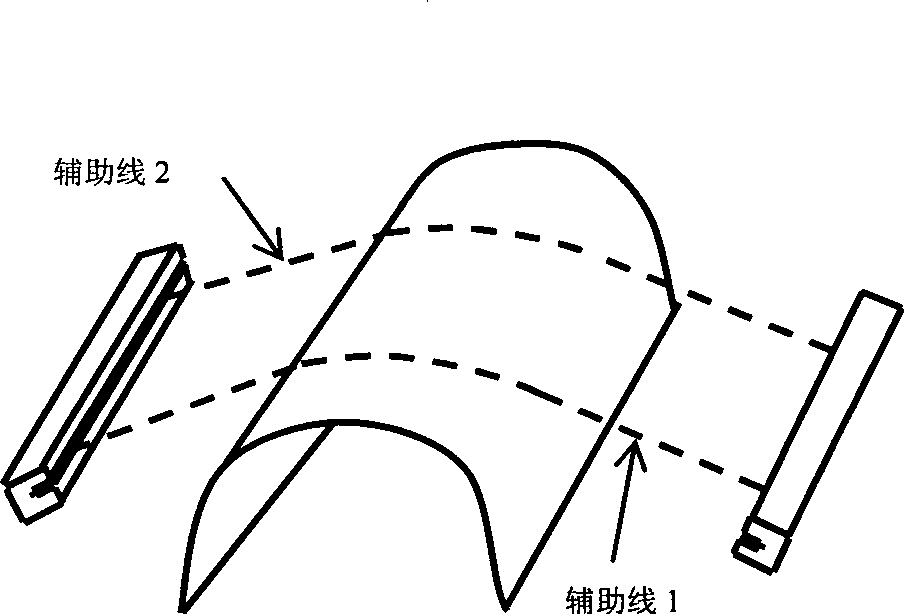

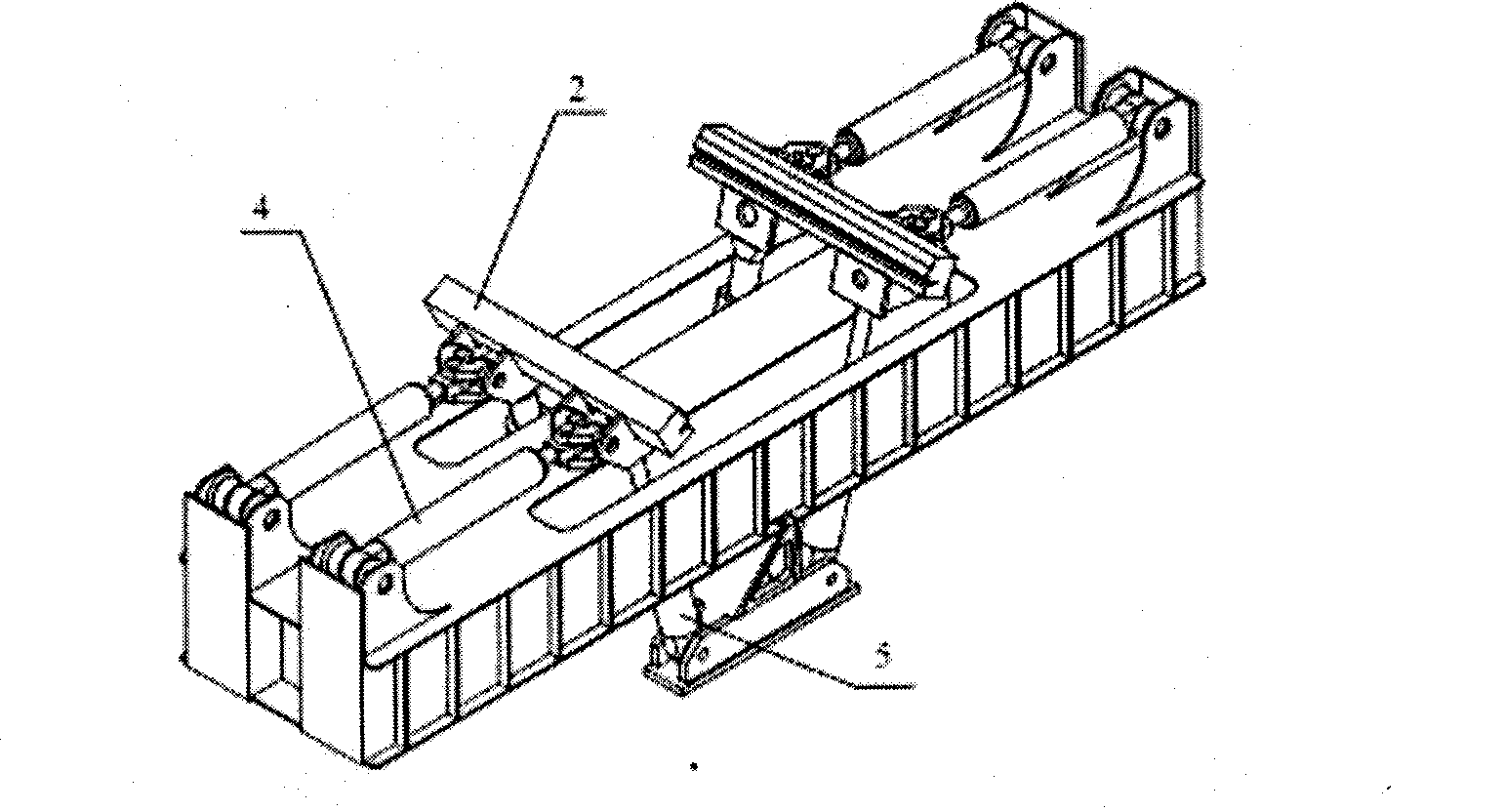

[0060] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 As shown, an aircraft skin transverse stretch loading trajectory design and CNC code generation method based on ACB FET series CNC transverse drawing machine. The specific implementation steps of the method are as follows:

[0061] Step 1: Design of horizontal stretch loading trajectory

[0062] 1. Calculate the section line

[0063] To calculate the section line, first calculate each line segment where the finite element mesh object intersects the plane. The basic algorithm is to traverse all the cells in the grid object, calculate the intersections between the cells and the plane, and connect the intersections in an orderly manner.

[0064] Before the algorithm analysis, according to the principle of computer floating point calculation, it is basically defined as:

[0065] ① Set POS_ZERO=1e-6, NEG_ZERO=-1e-6;

[0066] ②If the variable x is less than z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com