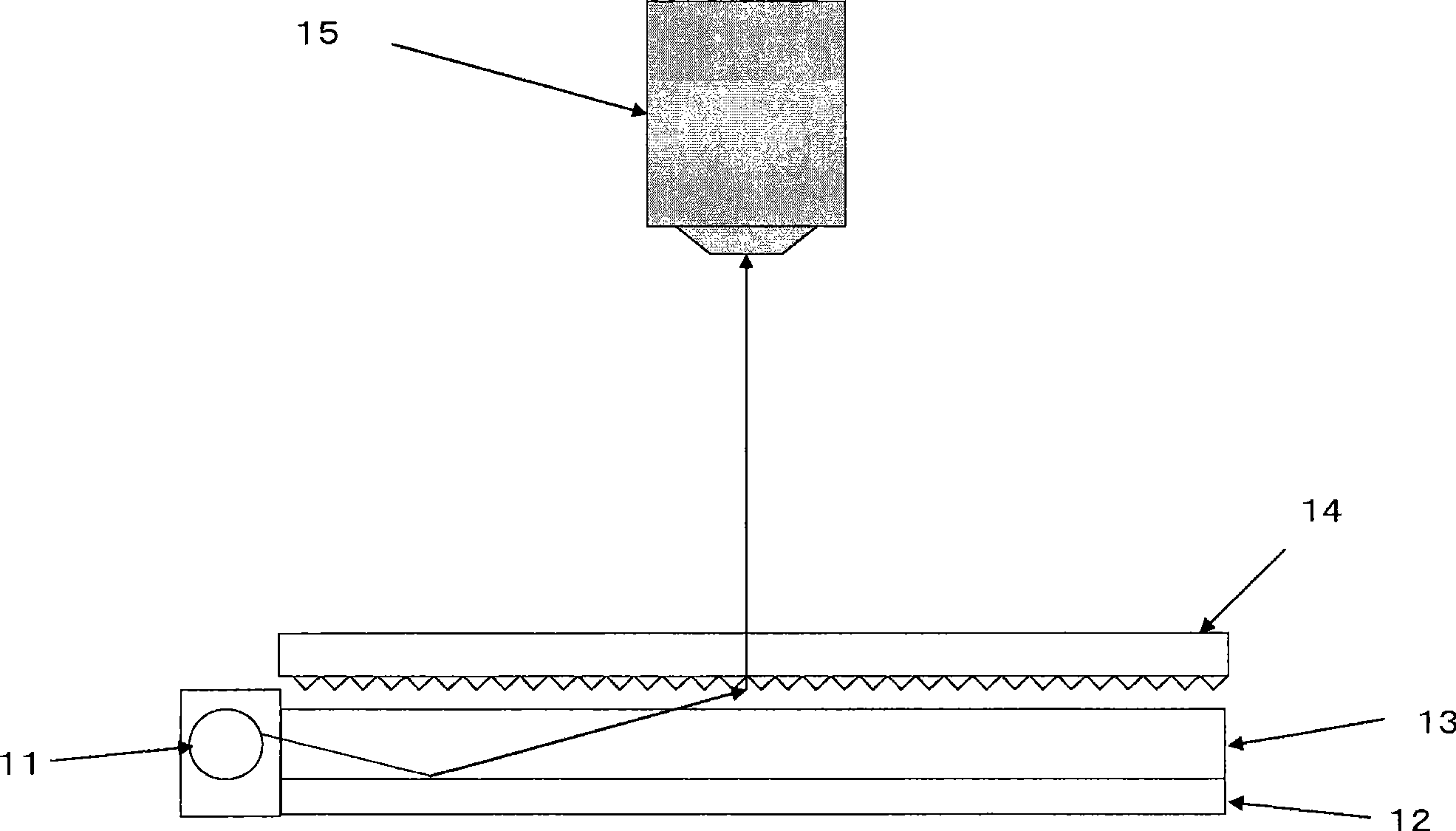

White polyester film for liquid crystal display reflector

A technology of liquid crystal display and polyester film, which is applied in the direction of instruments, chemical instruments and methods, coatings, etc., can solve the problems of liquid crystal display devices that are not suitable for light stability, achieve low pollution resistance, improve durability, reduce The effect of making losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

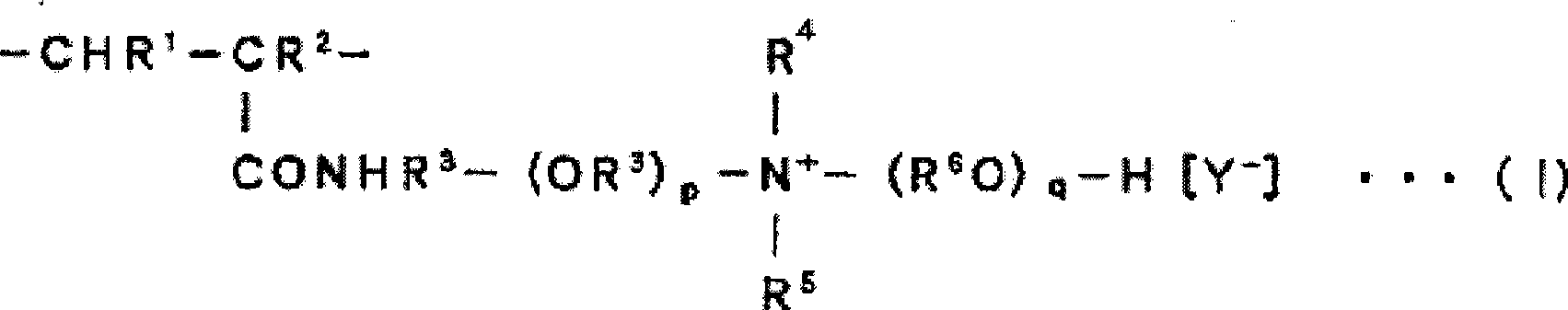

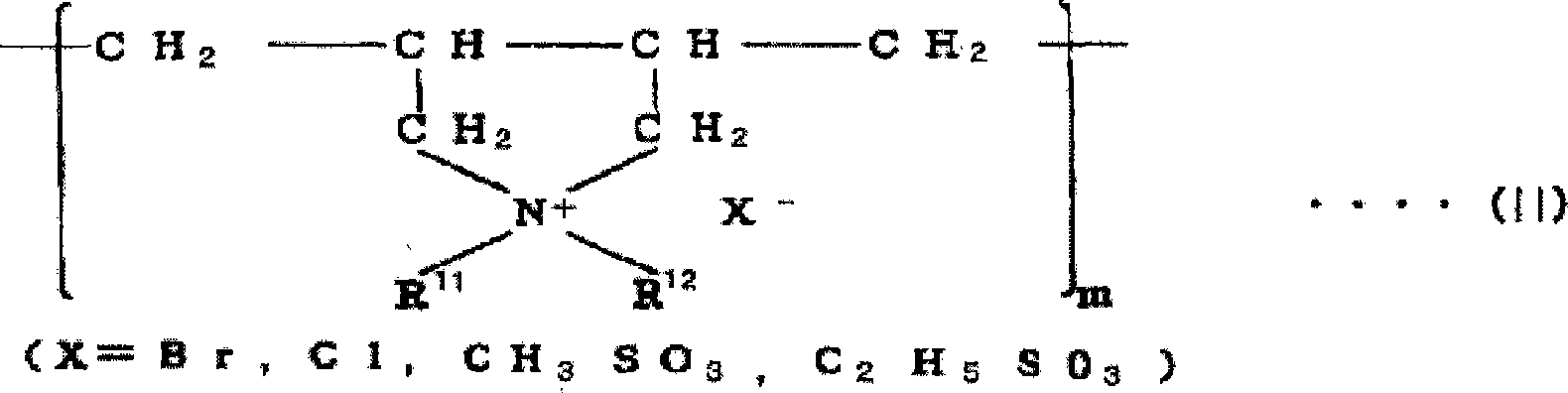

Method used

Image

Examples

Embodiment 1~19

[0215] The raw materials shown below were mixed according to the mixing ratio shown in Table 1. Extrusion temperature was made into 320 degreeC, this was supplied to the extruder A heated at 270-300 degreeC, and the base polymer of the polyester layer (A) was obtained.

[0216] ・Polyethylene terephthalate chip (F20S manufactured by Toray Co., Ltd.)

[0217] ・Copolymer of polyethylene glycol, polybutylene terephthalate, and poly(1,4-butylene glycol) with a molecular weight of 4,000 ("Hitrel" manufactured by Toray Dupont Co., Ltd.)

[0218] ・A copolymer obtained by copolymerizing 10 mol% of isophthalic acid and 5 mol% of polyethylene glycol in polyethylene terephthalate (T794M manufactured by Toray Co., Ltd.)

[0219] ・Polymethylpentene (TPX820 manufactured by Mitsui Chemicals Co., Ltd.)

[0220]・Silicon dioxide particles having the average particle diameter described in Table 1

[0221] · Polyethylene naphthalate (manufactured by Aldrich, d=1.328, m.p.250-290° C.)

[0222] ...

Embodiment 20~52

[0231] Put the raw materials of polyester layer (A) and polyester layer (B) shown in Table 4 and 5 into two extruders heated to 280°C respectively, and use a multi-layer feeding die set for confluence to make it The layer configuration and layer thickness are as described in Table 4, and the sheet was molded into a sheet shape with a die while maintaining the laminated state. The sheet is then cooled and solidified by a cooling drum with a surface temperature of 25°C, and the cooled and solidified unstretched film is heated to 90°C and stretched 2.9 times in the longitudinal direction (longitudinal direction), using a group of rollers at 25°C Allow to cool. On one side or both sides of the uniaxially stretched film, by microgravure coating (microgravure) at 4 g / m 2 (Wet) coating amount The aqueous coating liquid shown below was coated.

[0232] Among them, in Tables 4 and 5, the copolyester used refers to the polyester obtained by copolymerizing the dicarboxylic acid compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com