3D electrode reactor and application to non-degradable organic wastewater treatment

A three-dimensional electrode and reactor technology, used in textile industry wastewater treatment, water/sewage treatment, oxidized water/sewage treatment, etc. Biochemical, ensuring the effect of meeting the emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

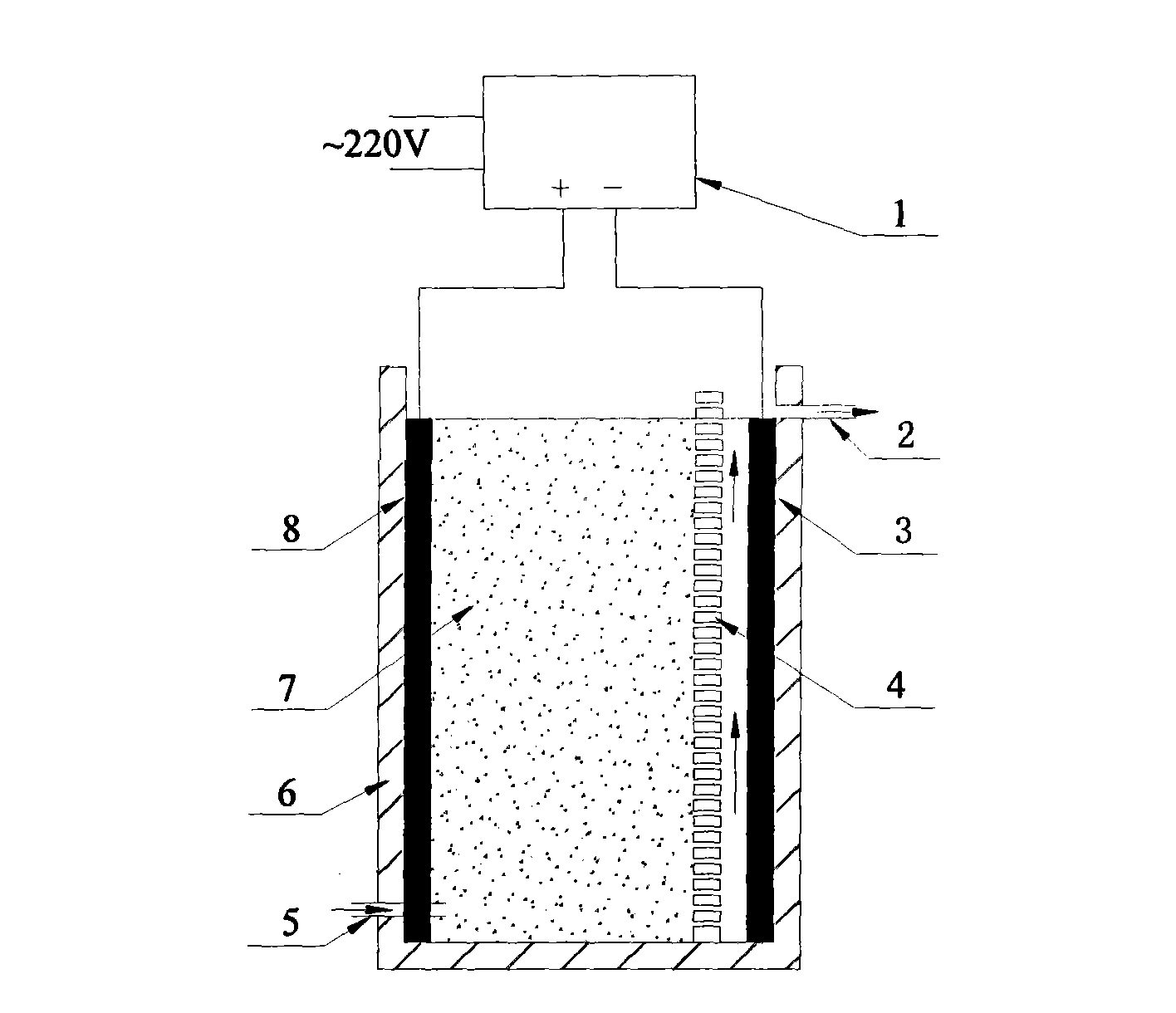

Method used

Image

Examples

Embodiment 1

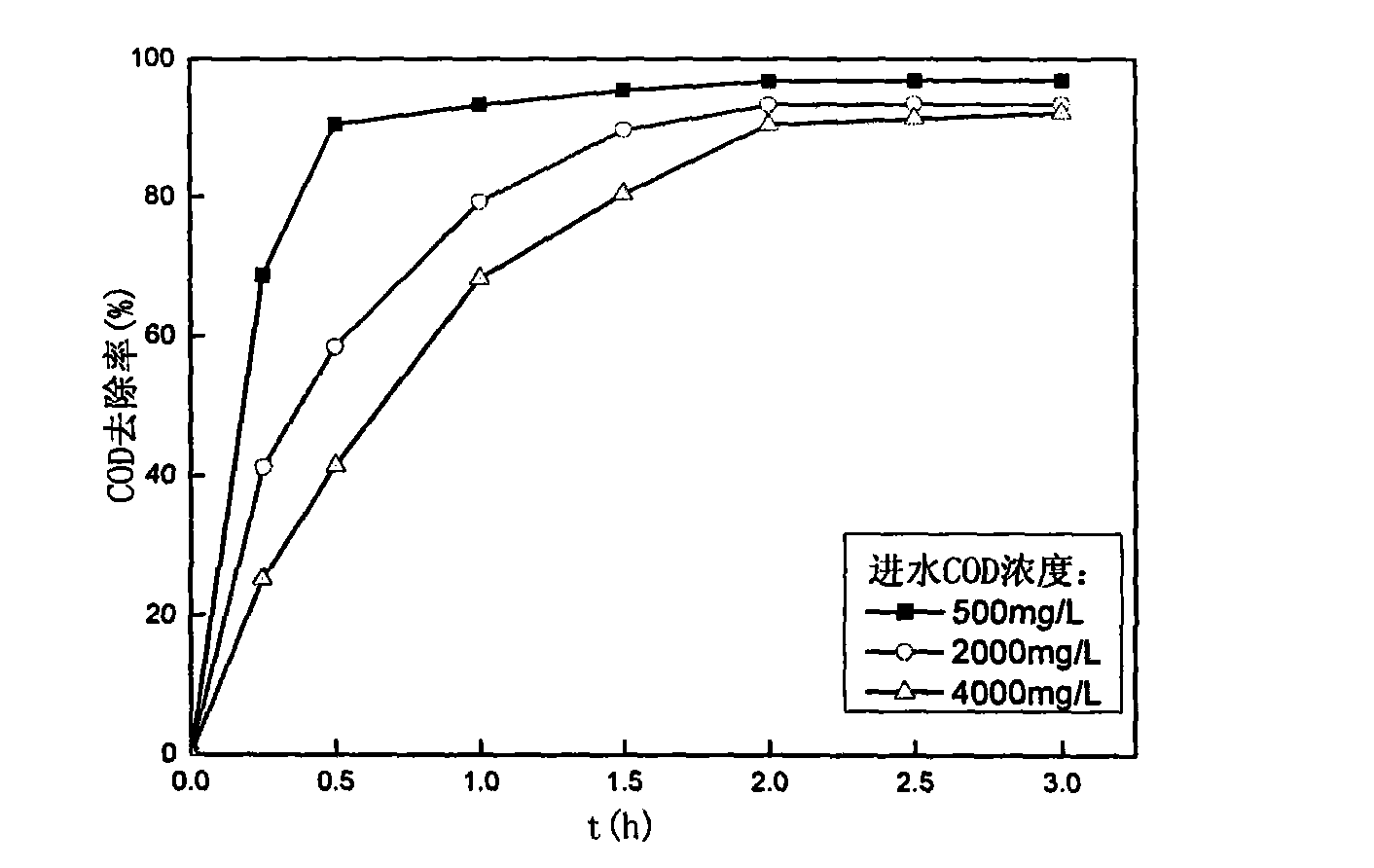

[0018] Using the three-dimensional electrode reactor of the present invention to treat EDTA wastewater, the control process conditions are: EDTA wastewater 500mL, pH value 7.7, water inflow rate 200mL / min, current density 40A / m 2 , when the influent COD is 500mg / L, the effluent COD is 46mg / L in 0.5h, and the removal rate reaches over 90%. Respectively 172mg / L and 194mg / L (see attached figure 2 ), reaching the national "Integrated Wastewater Discharge Standard" (GB8798-1996).

Embodiment 2

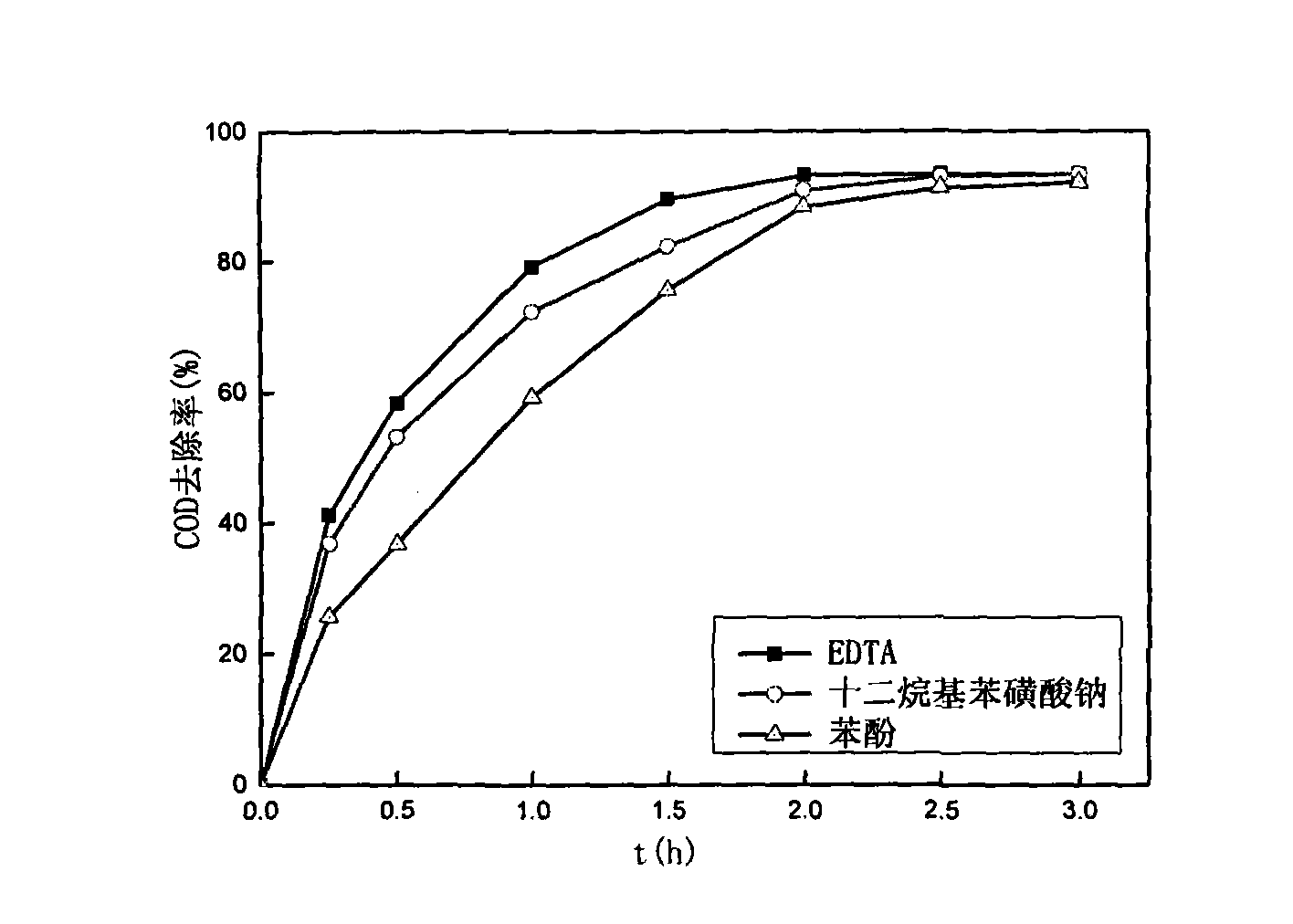

[0020] The waste water containing EDTA, sodium dodecylbenzenesulfonate and phenol is treated respectively with the three-dimensional electrode reactor of the present invention, the control process conditions are: waste water 500mL, influent pH value 7.7, influent COD concentration is 1000mg / L, influent Water velocity 200mL / min, current density 40A / m 2 , the effluent COD concentration was lower than 100mg / L in 3 hours, and the removal rate was higher than 90% (see attached image 3 ), reaching the first-level standard in the national "Integrated Wastewater Discharge Standard" (GB8798-1996).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com