Method for preparing low-emission thermal insulation film for laminated glass

A technology of laminated glass and film, applied in the field of preparation of low-e film, can solve the problems of not involving the energy-saving effect of laminated glass, and achieve the effects of mature production process, cost saving and tight sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

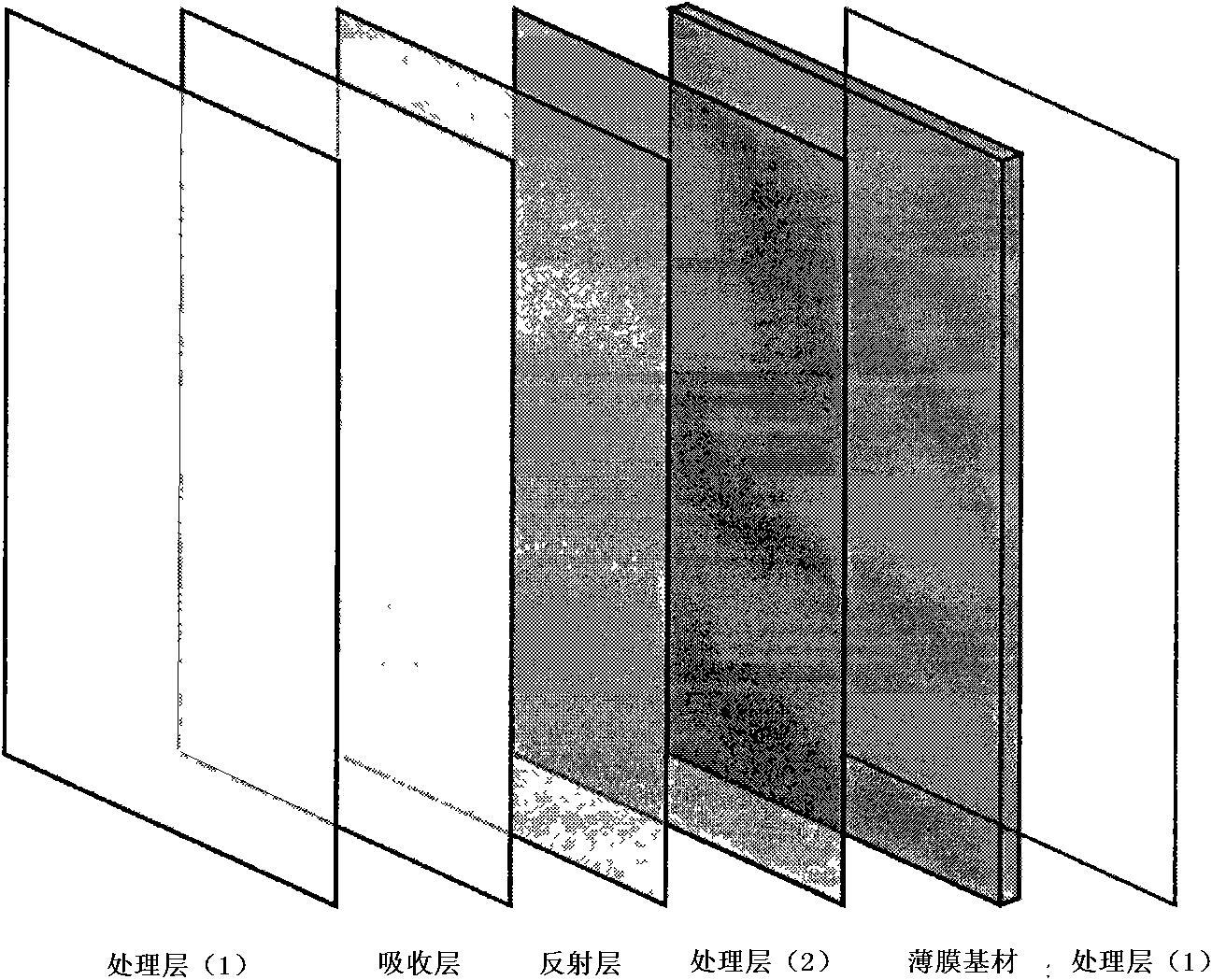

Image

Examples

Embodiment Construction

[0029] After treating the surface of the film substrate with a corona machine, pass the film through a low temperature of 50~120 degrees and a pressure of 1~3kg / cm 2 Then apply the surface treatment liquid and quickly dry it at 50~80 degrees; apply the reflective layer through a coating machine, and dry it at 50~80 degrees; apply the absorbing layer, and dry it at 50~80 degrees Drying at 80 degrees; after double-sided coating surface treatment on the surface of the film with a double-sided coating agent, the process is completed after drying at 50-80 degrees.

[0030] Beneficial effects of the present invention:

[0031] With reference to relevant national standards, the present invention: a kind of preparation method that can be used for the low-e film of laminated glass, can use the relevant detection method of laminated glass and the relevant detection method of low-e glass to utilize the low-e film that the present invention makes e laminated glass for detection. For spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com