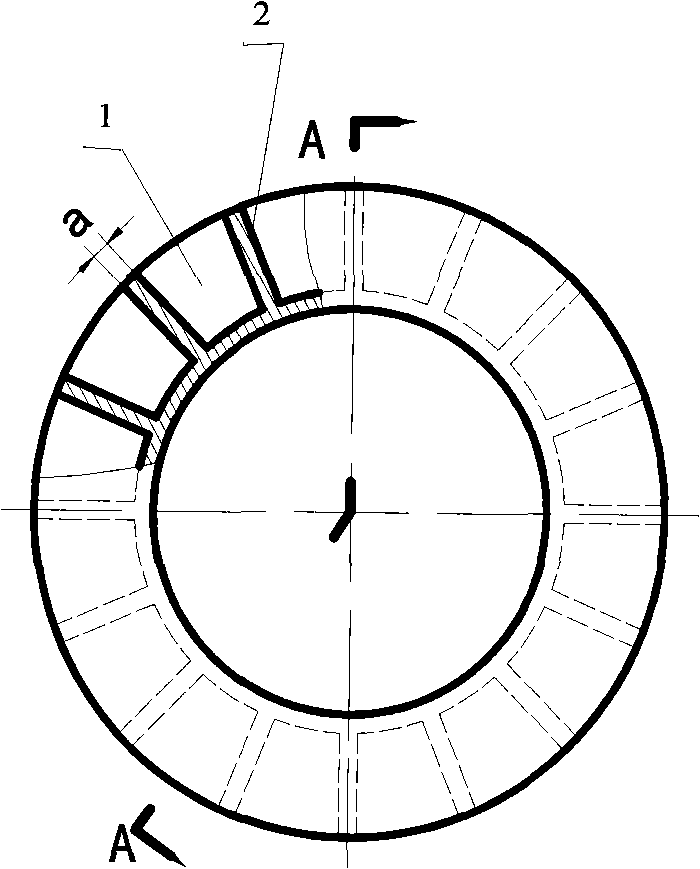

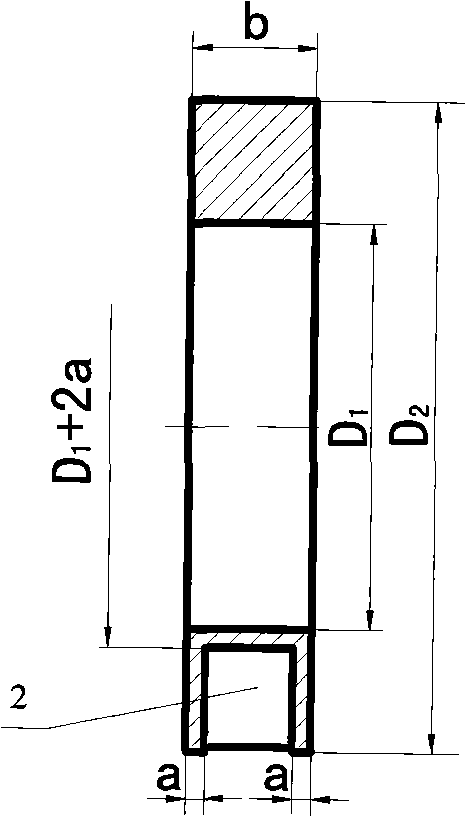

Shell-shaped mechanical seal ring with sector deep groove inside

A technology of mechanical seals and seal rings, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve problems such as uneven heating, achieve force balance, prolong service life, enhance seal lubrication and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Example: for D 2 =50mm,D 1 =36mm, b=20mm sealing ring, 16 grooves can be opened to form 16 axial ribs, the value of a can be taken as 2mm, and the groove depth is 5mm. The machining allowance should be considered for each surface, especially the sealing end surface. According to this Make a mold; make and sinter the blank of the sealing ring according to the mold; process the blank according to the technical requirements of the sealing ring; then process the shape of the sealing end face to obtain a high-performance sealing ring. When the seal is assembled, the groove should be exposed so that the medium can circulate and achieve the desired effect.

[0017] For sealing rings of different sizes, the number of grooves and the thickness a of the ribs can be determined according to the actual situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com