Piston bucket type low-pressure vapor drain valve

A low-pressure steam, bucket-type technology, applied in the direction of steam traps, mechanical equipment, etc., can solve the problems that cannot meet the technical requirements for the selection of ethylene steam traps, and achieve the elimination of air blockage and steam lock, sensitive action, and steam leakage small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

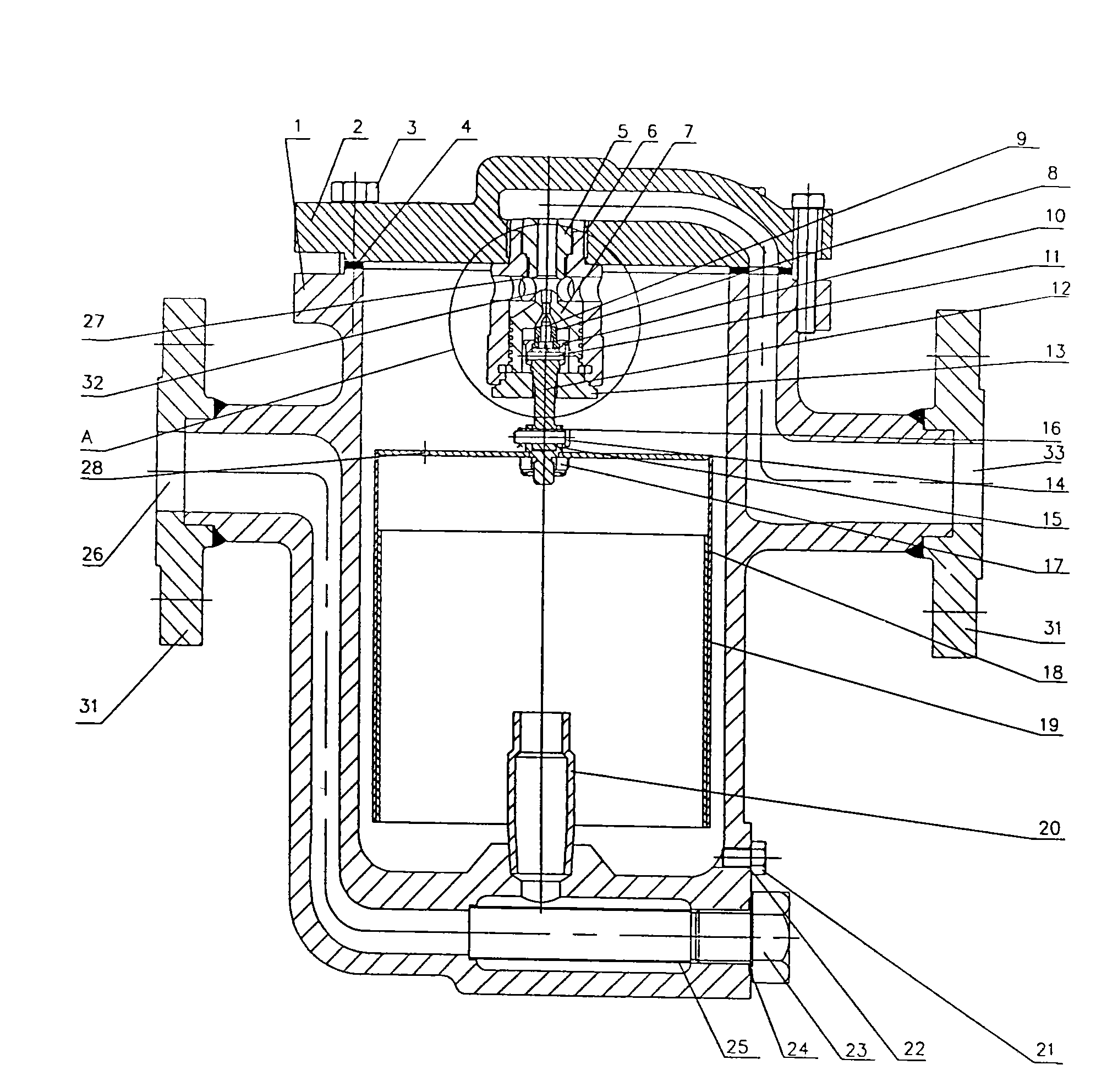

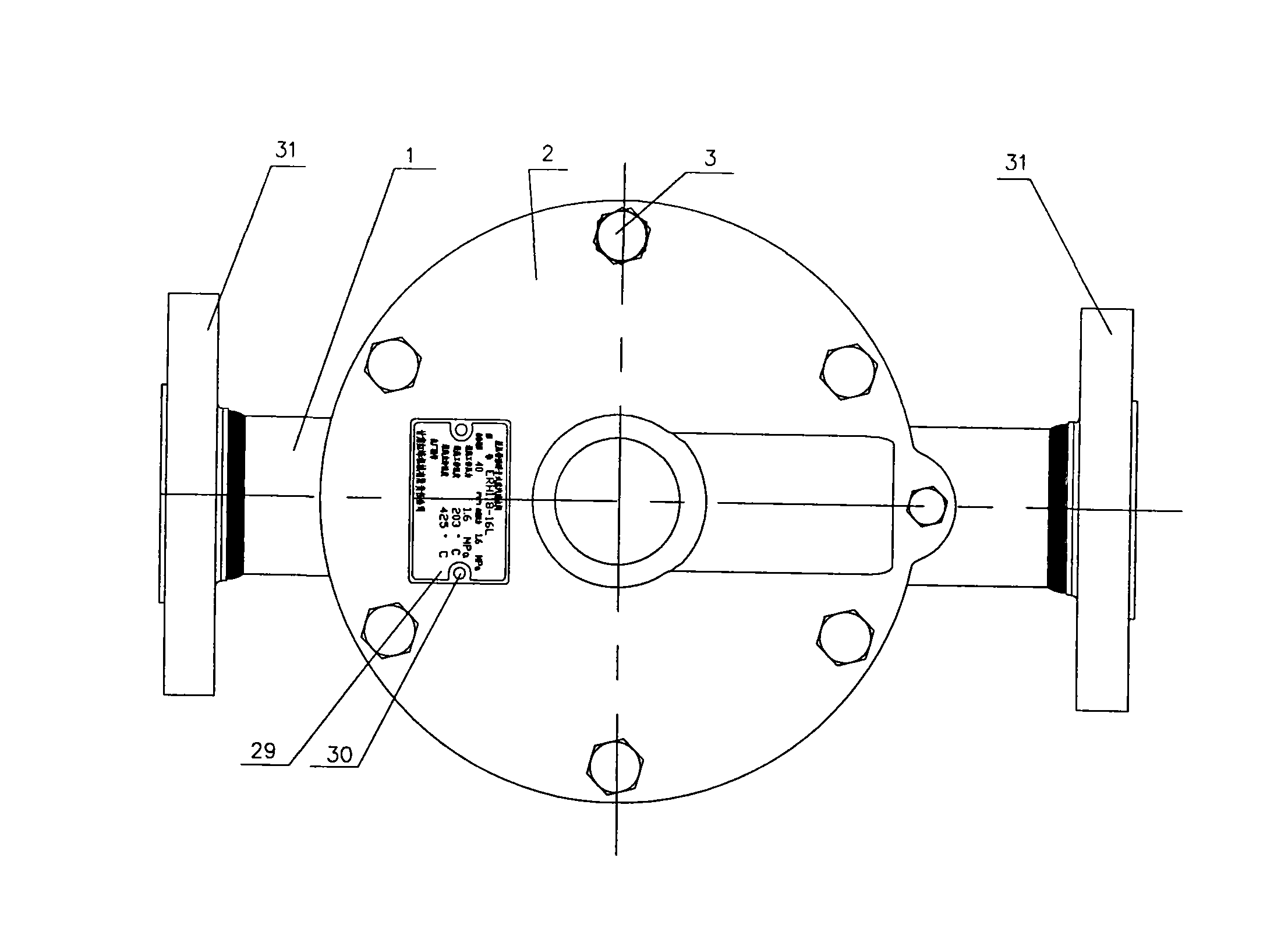

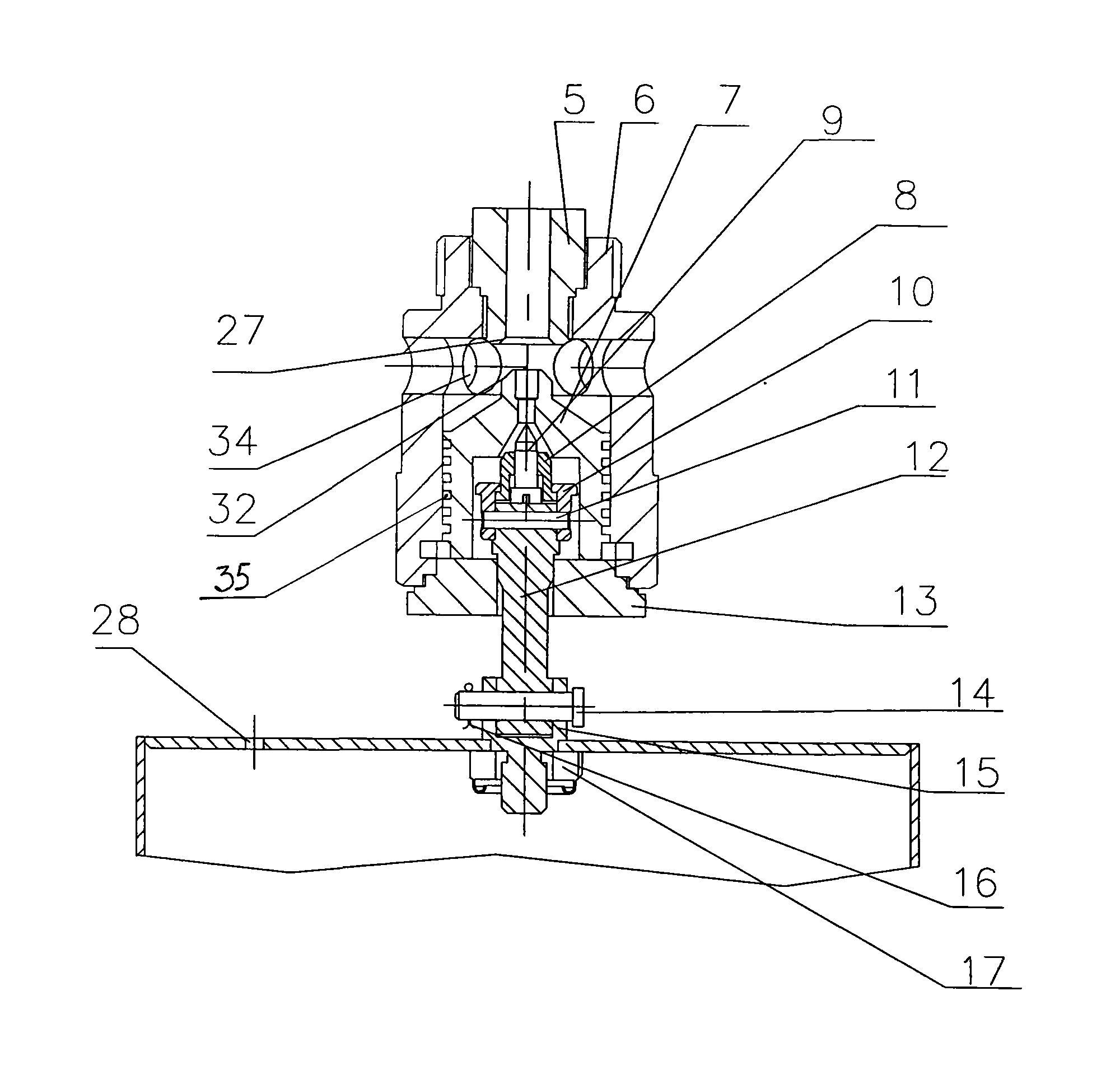

[0017] exist figure 1 , 2 , 3, 4, and 5: the left and right sides of the valve body 1 are respectively provided with an inlet hole 26 and an outlet hole 33 for the working medium, and a hole is provided on the valve body 1 along the inlet hole 26 to communicate with the inlet hole 26 , A hole is provided on the valve body 1 upward along the outlet hole 33 , communicating with the outlet hole 33 . The valve cover 2 is provided with a hole, one end of the hole communicates with the main valve seat 5 , and the other end communicates with the outlet hole 33 . The signboard 29 is fixed on the top left side of the valve cover 2 with a signboard rivet 30 . Valve body 1 and bonnet 2 are PN25 in terms of strength and pressure. They are all made of WCB castings at one time, which can meet the safe use requirements of steam traps at a maximum allowable temperature of 260°C and a pressure (maximum allowable pressure of 1.7MPa·G). The wall thickness and pressure level of the valve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com