Semiconductor laser tube core sintering device and usage thereof

A sintering device and laser technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the impact of laser device stability, reliability, life and yield, shift of light emitting direction, and uneven contact between chips and heat sinks and other problems, to achieve the effect of solving low luminous efficiency, reducing series resistance and thermal resistance, and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below in conjunction with accompanying drawing:

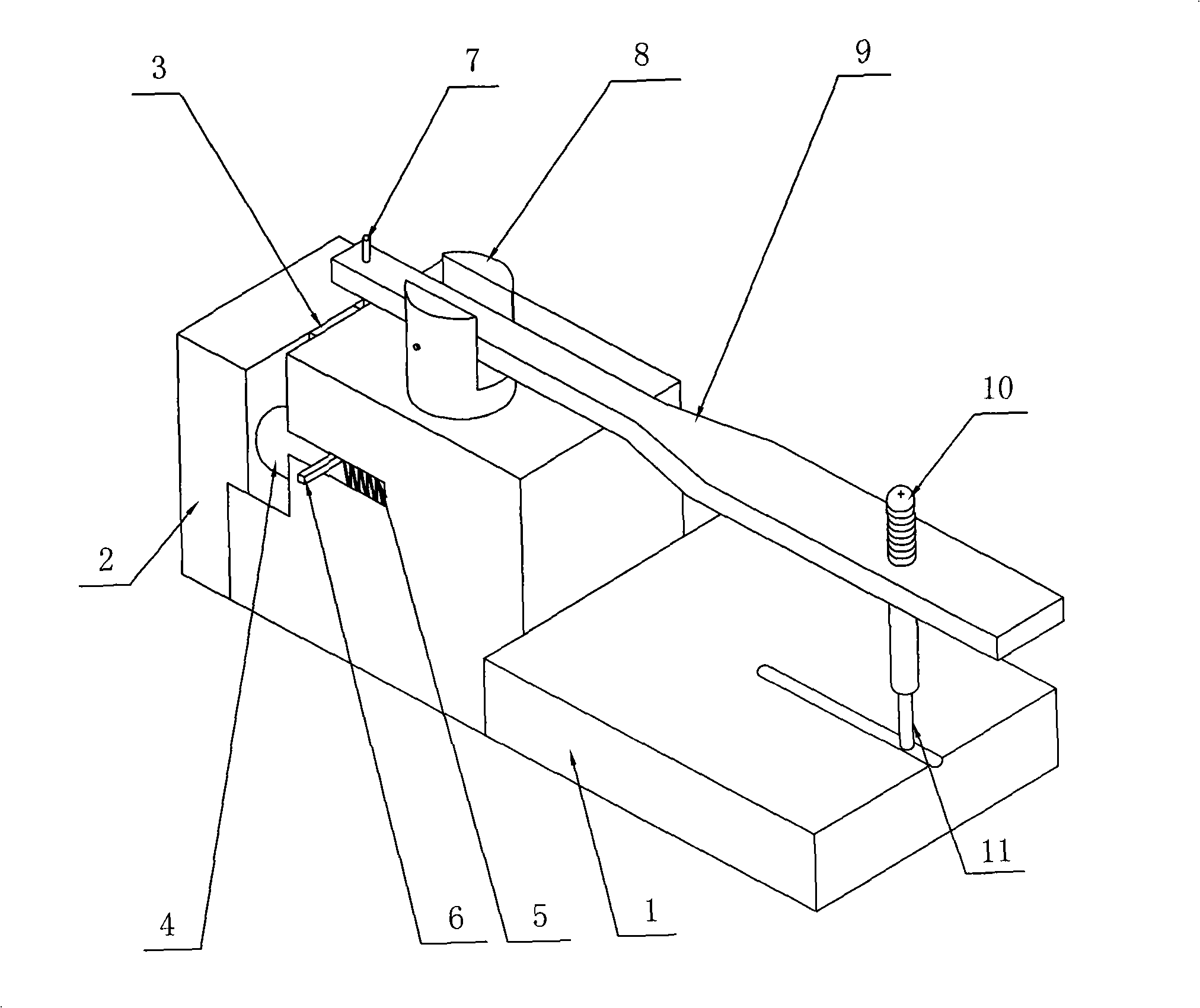

[0016] Such as figure 1 As shown, the semiconductor laser tube core sintering device of the present invention includes a bottom support 1, a front baffle plate 2, a heat sink 3, a pressure spring column 4, a spring 5, a puller 6, a pressure pin 7, a pillar 8, and a pressure rod 9 , the elastic pillar 10 and the sliding foot 11, the bottom support 1 and the front baffle 2 are fixedly connected by screws, the heat sink 3 is connected with the compression spring column 4 in contact, the spring 5 is elastically connected with the dial lever 6, and the pressure pin 7 is connected to the warp The pressure rod 9 is fixedly connected by screws, the pillar 8 is fixedly connected with the warping pressure rod 9 through chips, the warping pressure rod 9 is threadedly connected with the elastic pillar 10, the elastic pillar 10 is connected with the sliding foot 11 through spring c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com