Vibration crushing type pill dropping machine

A dropping pill machine and dropping pill technology are applied in the direction of making medicines into special physical or ingestible devices, etc., which can solve the problem of high cooling temperature gradient control requirements, inability to adjust the weight of dropping pills online, and limited scope of application, etc. problem, to achieve the effect of improving operability, simple structure and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

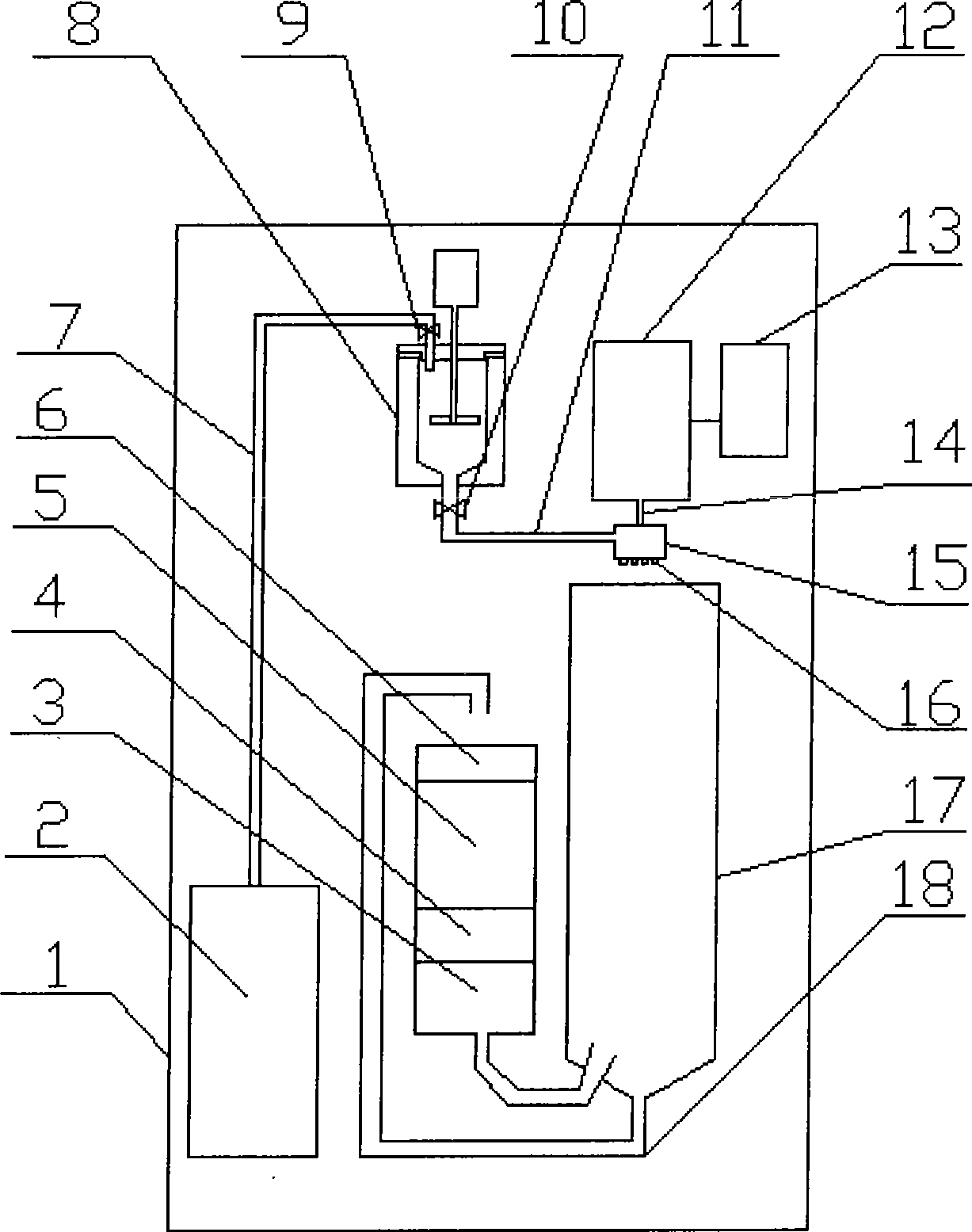

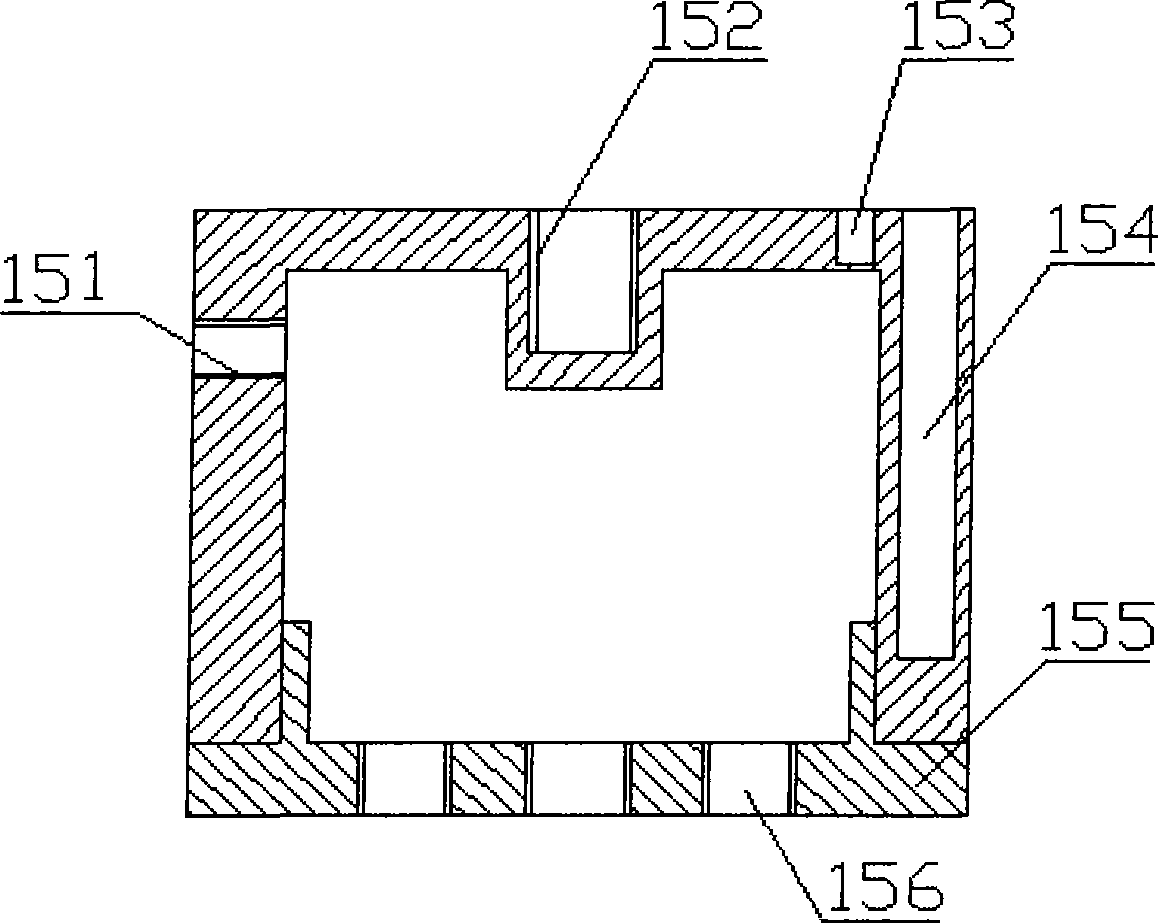

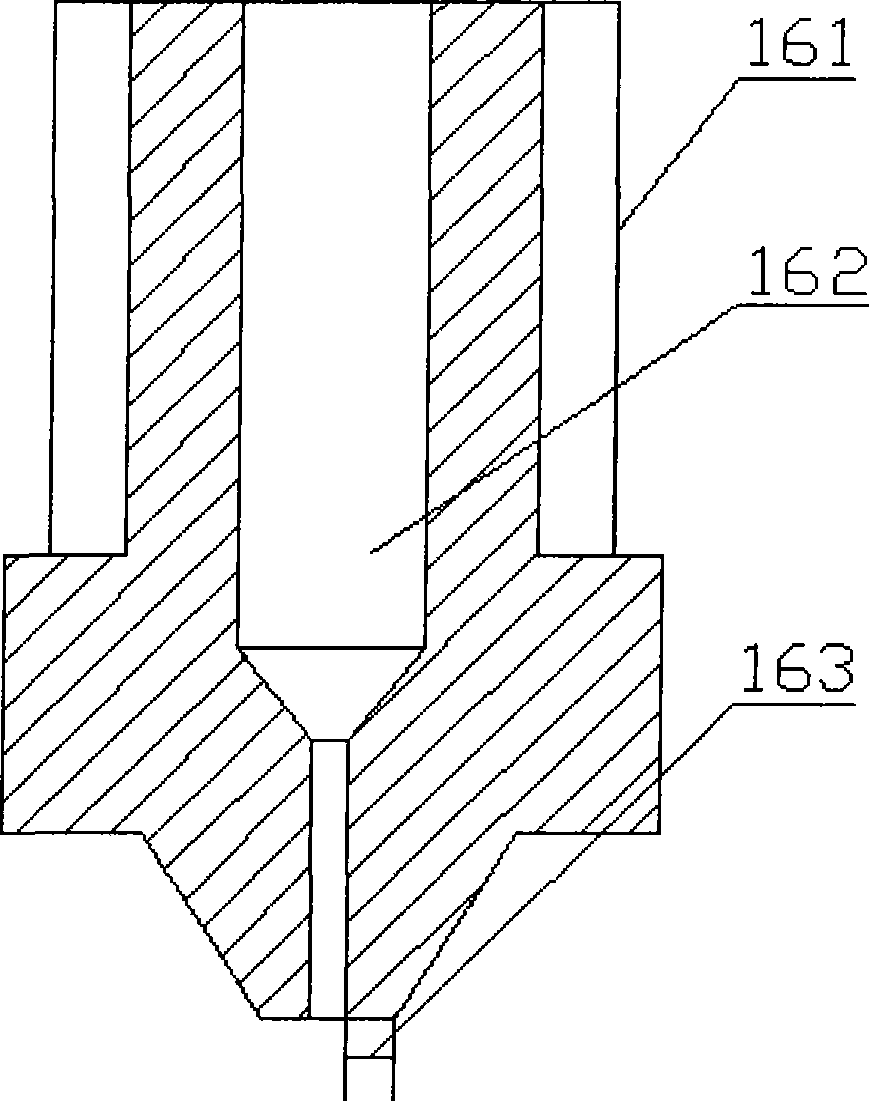

[0040] The following combination figure 1 , figure 2 , image 3 And a preferred embodiment describes the present invention in detail.

[0041] figure 1 The overall structure of the dripping pill machine in the present invention is shown. Depend on figure 1 It can be seen that the vibration-crushing dropping pill machine of the present invention includes a housing 1, and the dropping pill system, a vibration-breaking system and a cooling circulation system are arranged in the housing 1.

[0042] The dripping pill system includes a liquid storage tank 8, an air pump 2, and a dropper 15; the upper port of the liquid storage tank 8 is connected with the air pressure pump 2 through a pipeline 7 provided with a first valve 9, The lower port of the liquid storage tank 8 is connected to the dripper 15 through the hose 11 provided with the second valve 10, and several spray holes 16 are installed at the lower end of the dripper 15;

[0043] In order to facilitate the mixing and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com