Halogen-free glass fiber reinforced nylon resin and preparing method thereof

A nylon resin and nylon technology, applied in the field of halogen-free glass fiber reinforced nylon resin and its preparation, can solve the problems of high cost and difficulty in popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

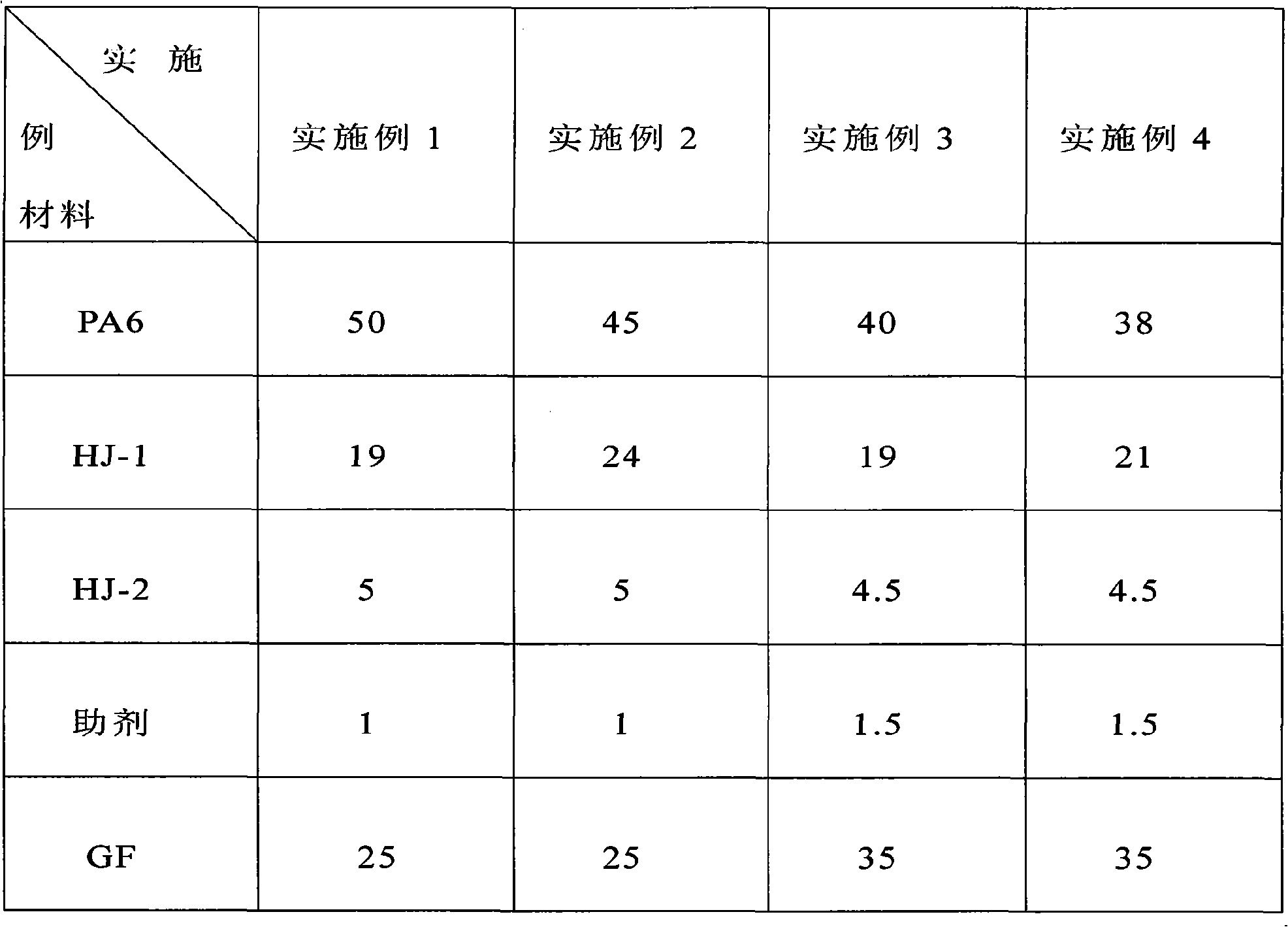

Embodiment 1~4

[0017]

[0018] HJ-1: intumescent flame retardant with special phosphorus nitrogen structure

[0019] HJ-2: toughening agent

[0020] GF: glass fiber

[0021] Nylon is dried in a drying hopper at 90-110°C for 3-4 hours, and the formula amount of nylon 6 (PA6), phosphorus-nitrogen structure halogen-free intumescent nylon flame retardant (HJ-1), toughening agent (HJ- 2) After mixing all kinds of additives evenly in the high-speed mixing bucket as required, add them from the mixing port until the temperature is set at 220-270°C, and the length-to-diameter ratio (L / D) is 32:1-40:1. The screw combination is vacuumized and granulated in a twin-screw extruder specified by the process to make a halogen-free glass fiber reinforced nylon 6 resin. The sampled material was dried at 90-110°C for 3-4 hours and then injection-molded into a standard sample for performance testing. The performance is shown in Table 2.

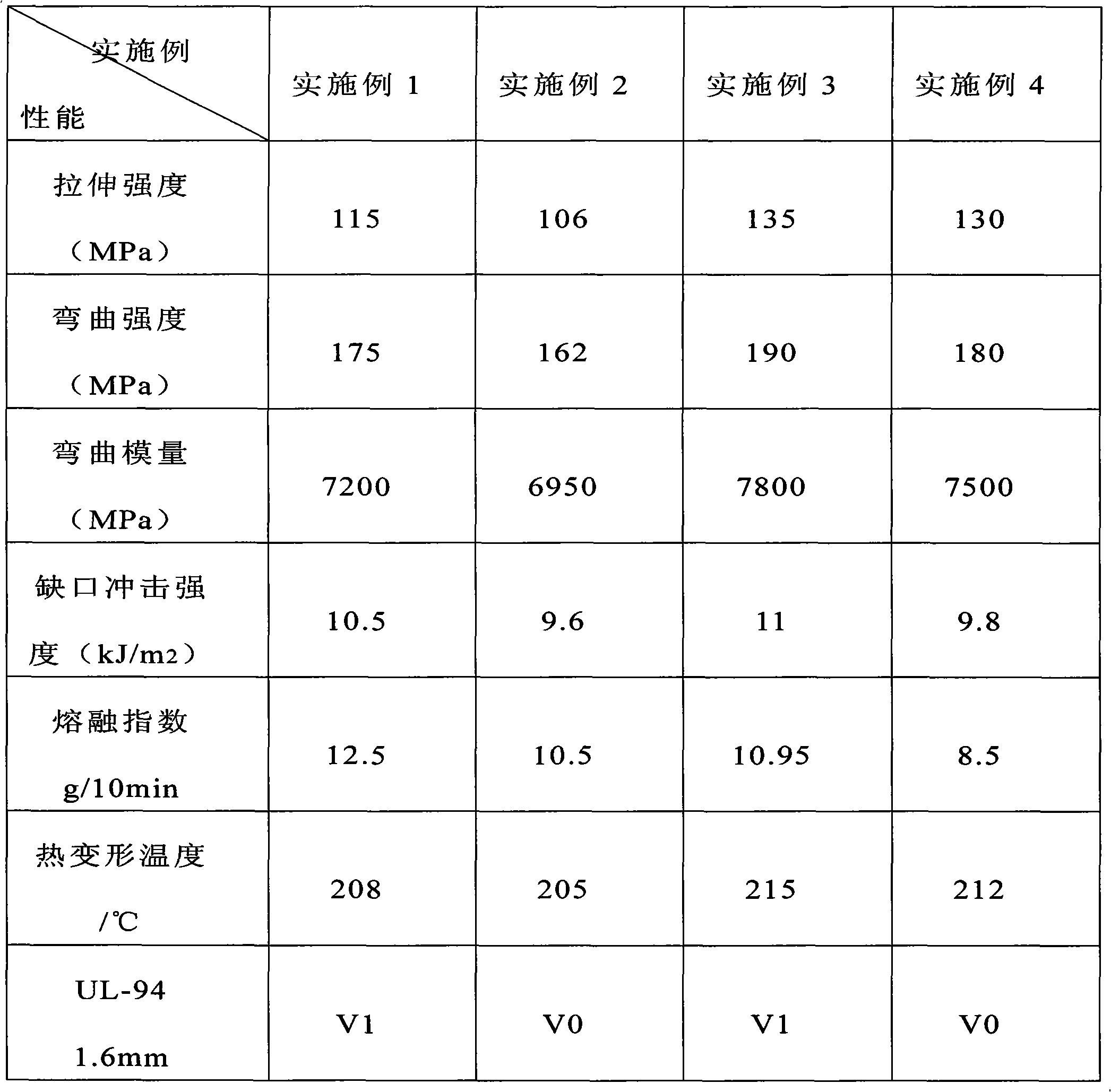

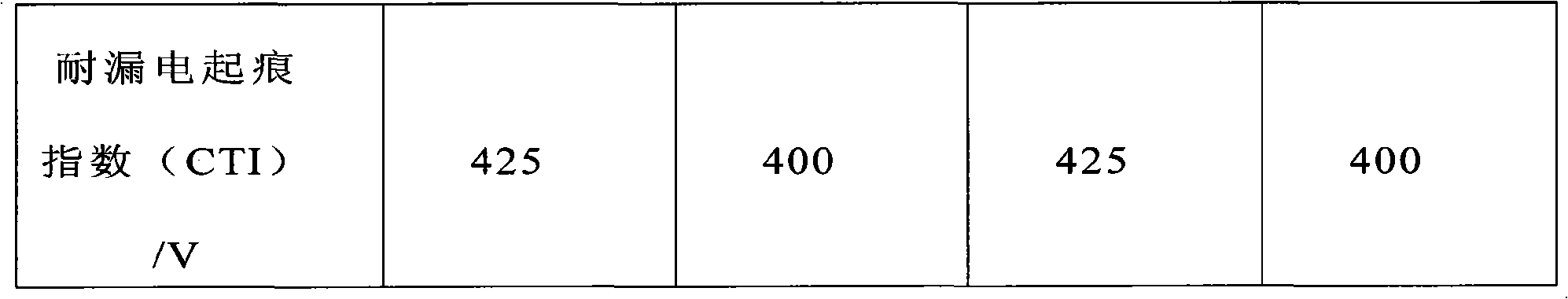

[0022] The performance test result of table two embodiment 1~4

[0...

specific Embodiment approach 2

[0025] Halogen-free glass fiber reinforced nylon 66 resin

Embodiment 5~8

[0027]

[0028] HJ-1: intumescent flame retardant with special phosphorus nitrogen structure

[0029] HJ-2: toughening agent

[0030] GF: glass fiber

[0031] Nylon 66 is dried in a drying hopper at 90-110°C for 3-4 hours, and the formula amount of nylon 6 (PA6), phosphorus-nitrogen structure halogen-free intumescent nylon flame retardant (HJ-1), toughening agent (HJ -2) After mixing all kinds of additives in the high-speed mixing bucket according to the requirements, add them from the mixing port until the temperature is set at 230-280°C, and the length-to-diameter ratio (L / D) is 32:1-40:1 , Screw combination In the twin-screw extruder specified by the process, vacuumize and granulate to make halogen-free glass fiber reinforced nylon 66 resin. The sampled material was dried at 90-110°C for 3-4 hours and then injected into a standard sample for performance testing. The performance is shown in Table 4.

[0032] The performance test result of table four embodiment 5~8

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com