Production line for polyethylene fiber single-oriented presoaked belts

A polyethylene fiber and production line technology, applied to the surface coating liquid device, textile and papermaking, coating and other directions, to achieve the effect of uniform gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention provides a production line of polyethylene fiber unidirectional prepreg tape, and the following examples illustrate the specific implementation of the polyethylene fiber unidirectional prepreg tape production line provided by the present invention.

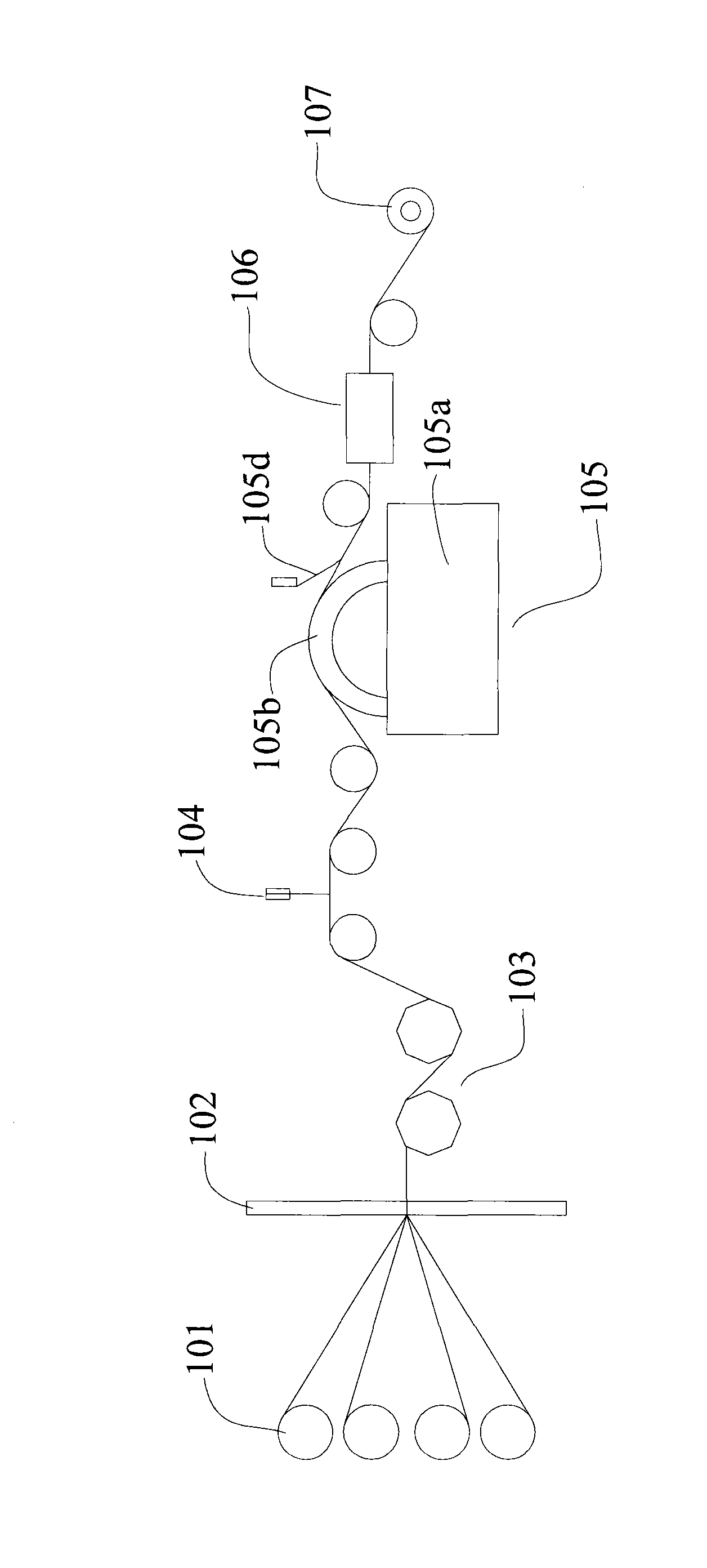

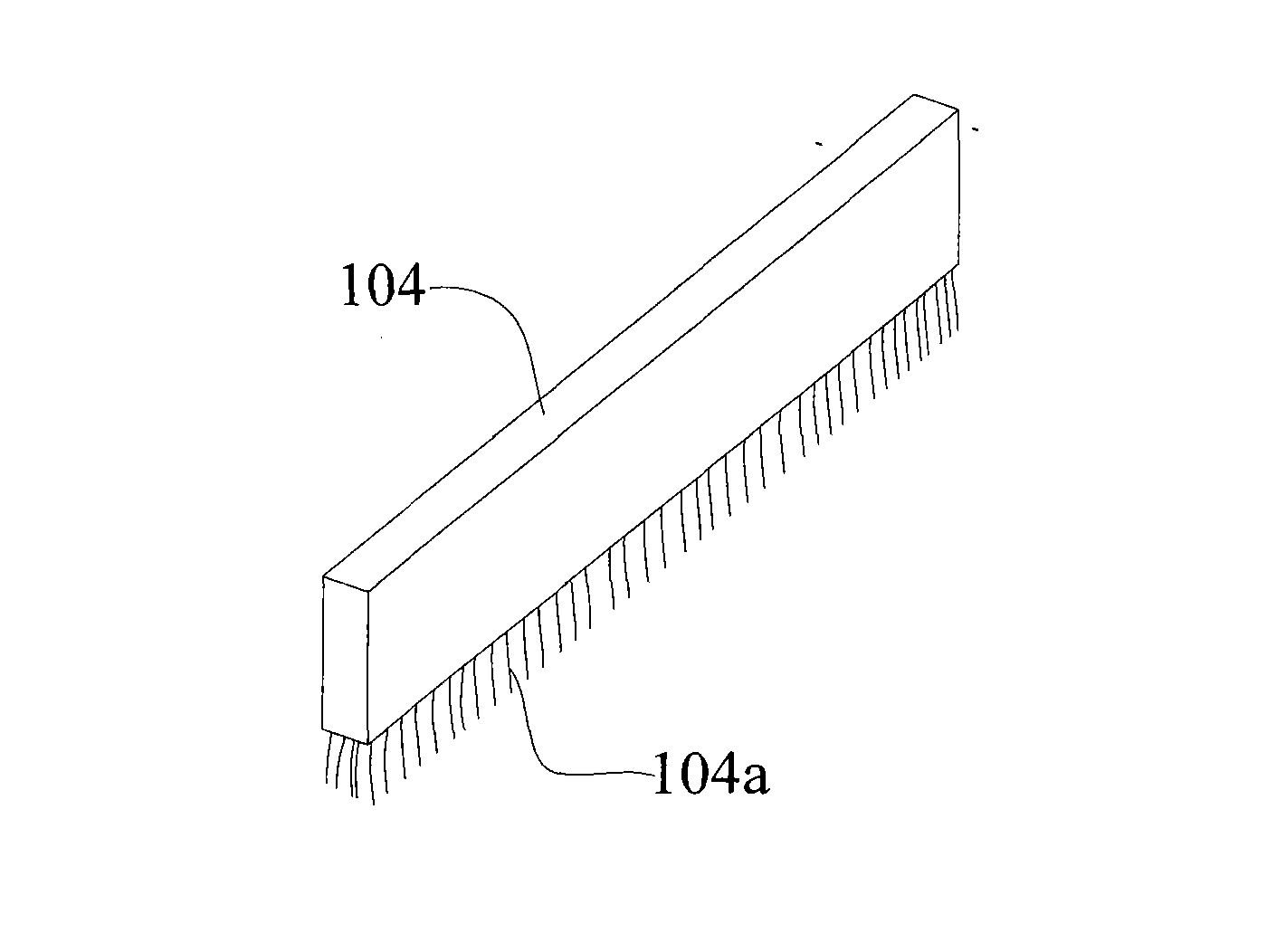

[0027] see Figure 1 to Figure 3 , figure 1 The schematic diagram of the polyethylene fiber unidirectional prepreg tape production line provided for the first embodiment of the present invention includes successively a creel 101 supporting polyethylene fiber spindles, and the creel 101 can realize continuous filament feeding by supporting several spindles. There is a mechanical damper (not shown) to control the tension of the yarn, the mechanical damper can also be replaced by an electronic damper.

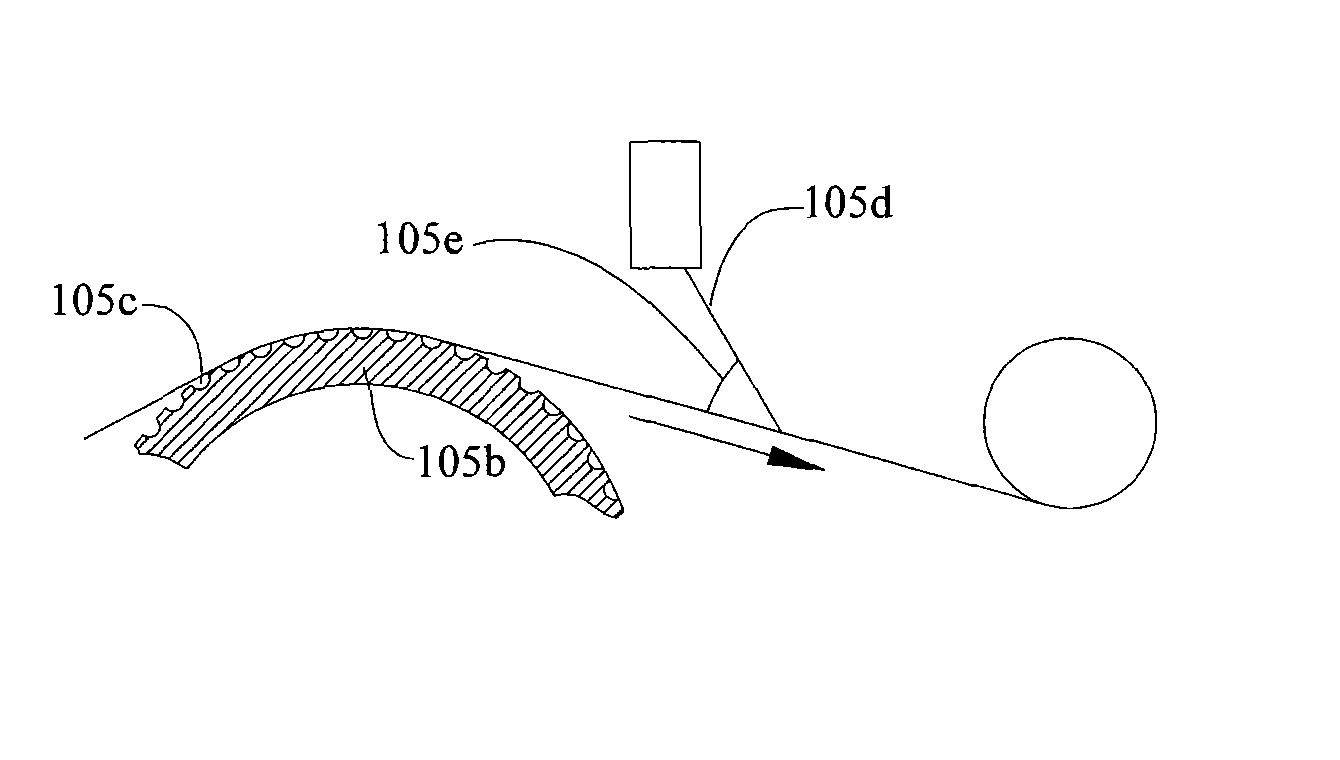

[0028] The spindles on the creel pass through the cluster frame 102, so that the orientation of each bundle of fibers is approximately the same. Behind the cluster frame 102 is an electrostatic generatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com