Sleeve dissipative element with shear key

An energy-consuming element and shear-resistant key technology, applied in the field of energy-consuming elements, can solve the problems of limiting the wide application of energy-consuming supports, high processing accuracy requirements, inconvenient maintenance and replacement, etc., and achieves simple construction, increased friction, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

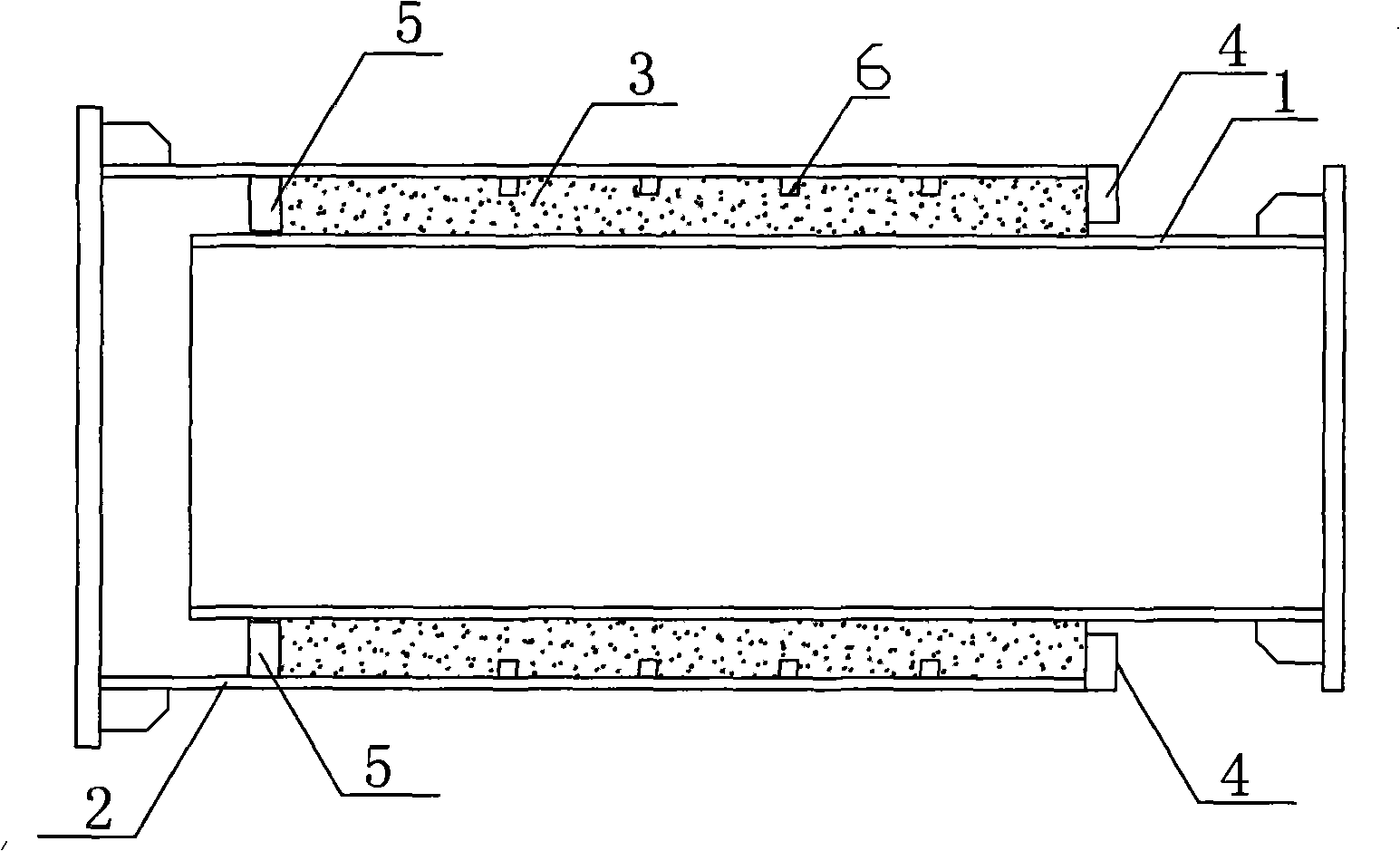

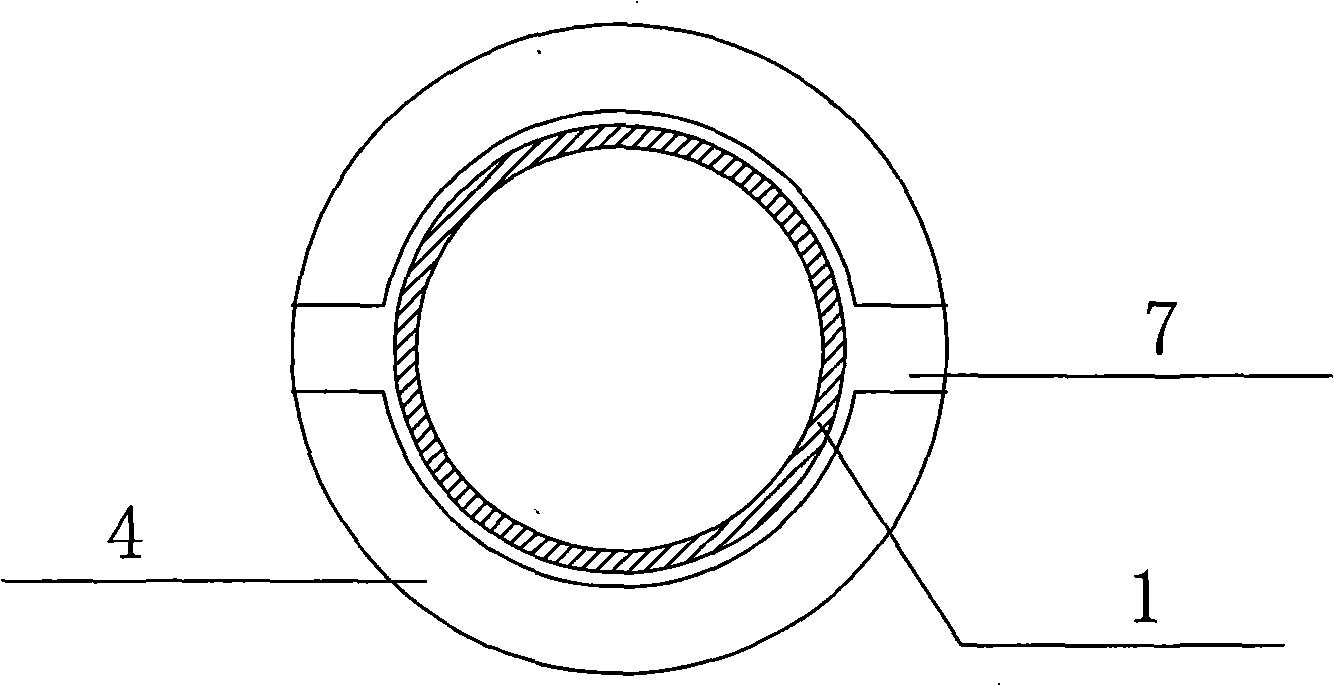

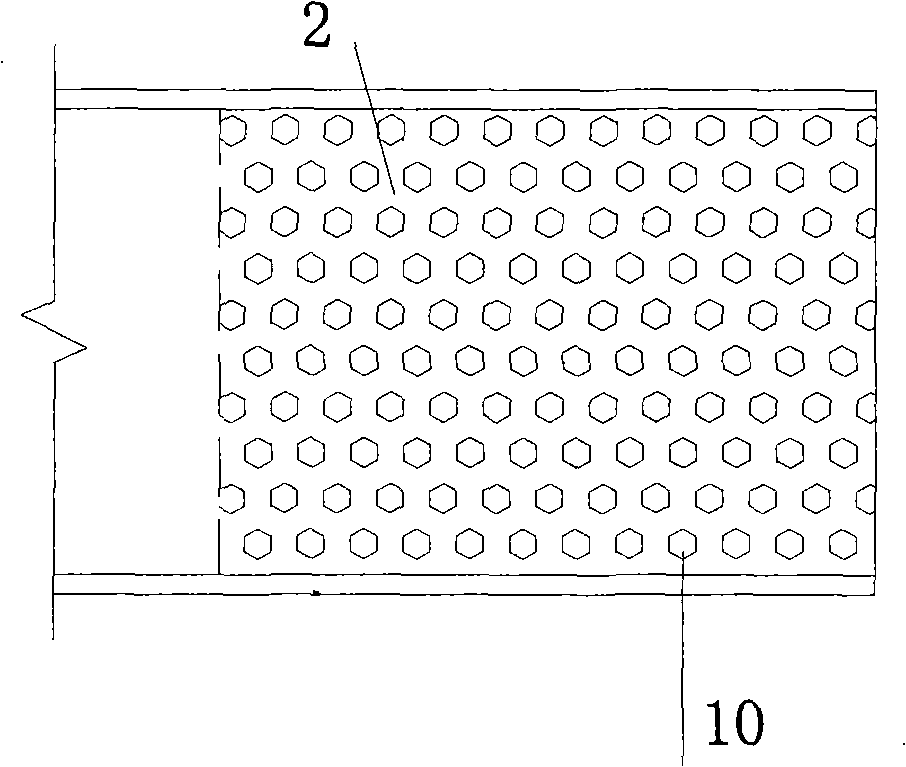

[0021] like figure 1 As shown, as an embodiment of the present invention, the energy-dissipating element of the grouting casing includes an inner pipe 1 and an outer pipe 2, the inner pipe 1 is inserted into the outer pipe 2 along the pipe axis and overlapped coaxially, the outer wall of the inner pipe 1 and the outer The surface of the inner wall of the pipe 2 can be sandblasted or shot blasted. The inner pipe wall of the overlapping section of the outer pipe 2 is provided with a shear key 6. The shear key is a solder joint. The overlapping section of the outer pipe 2 and the inner pipe 1 The outer end of the pipe is provided with an annular outer ring plate 4, and the inner end of the lap section of the outer pipe 2 and the inner pipe 1 is provided with an annular inner ring plate 5 (such as figure 2 shown), the outer ring plate 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com