Furnace cover of closed type calcium carbide furnace and process for producing same

A calcium carbide furnace and furnace cover technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as process operation and furnace difficulty, furnace pressure fluctuations, serious material spraying, etc., to avoid furnace gas and dust falling into the furnace. The effect of improving the quality structure of the material layer and saving the cost of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

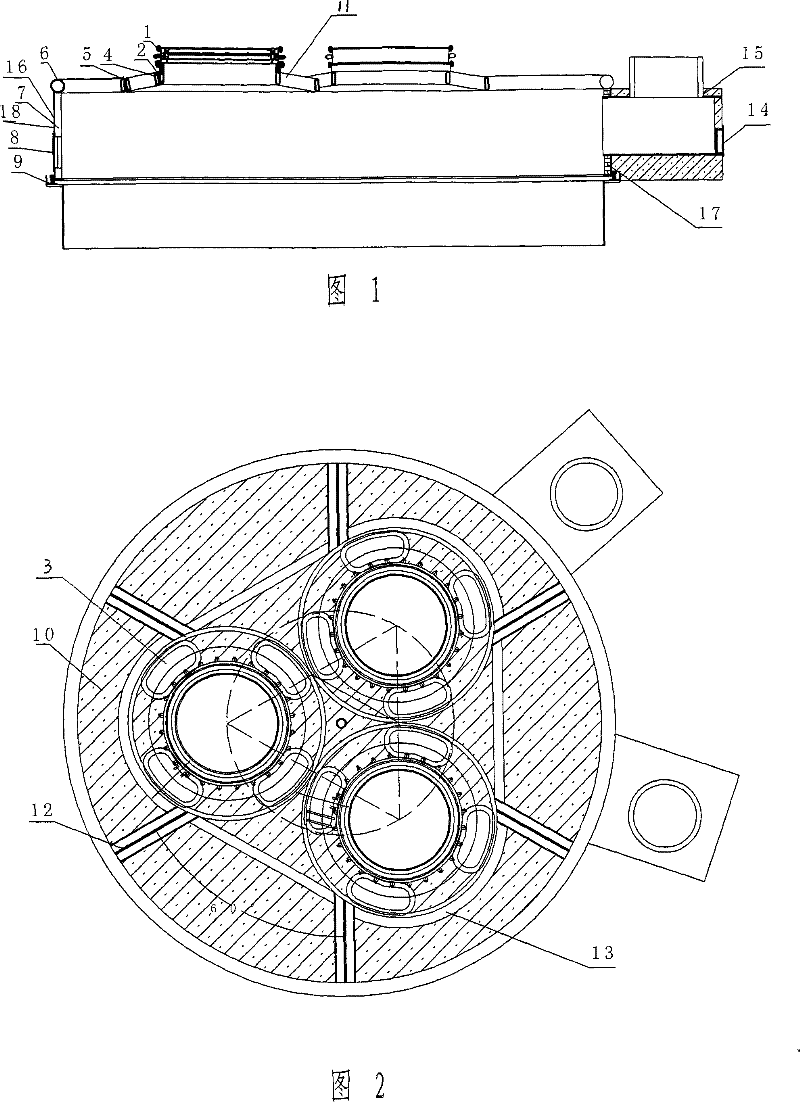

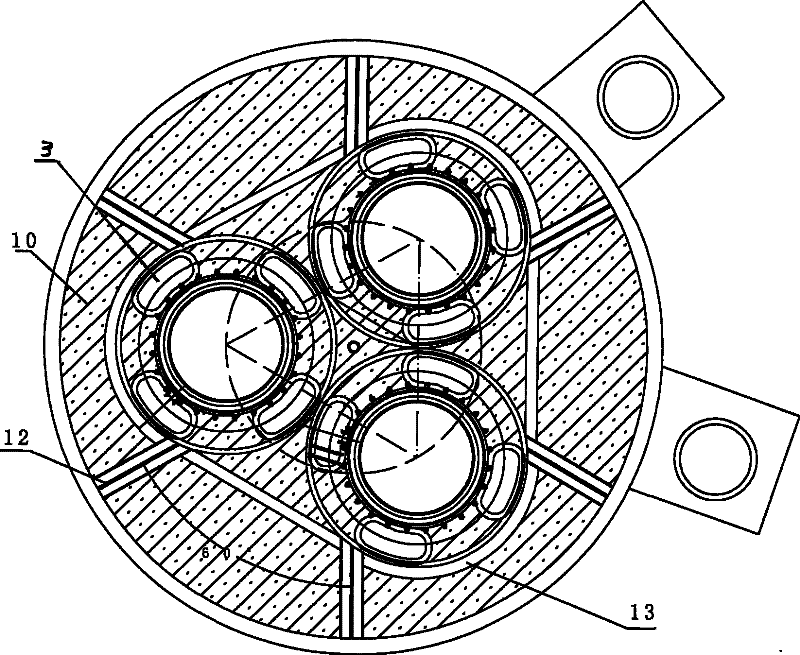

[0017] As shown in Figures 1 and 2, the furnace cover of the present invention is constituted as follows: there are three electrode sealing ring devices 1, and the electrode sealing ring devices are used to seal the furnace gas to prevent the furnace gas from protruding from the electrode column and contacting the air to burn, and the electrodes are sealed The ring device 1 is connected to the electrode water-cooled sealing sleeve 2 made of non-magnetic steel thick-walled seamless steel pipe by means of flange bolt connection, and each electrode water-cooled sealing sleeve 2 is installed with four feeding nozzles by welding The seat plate and the water-cooling ring 4 made of non-magnetic steel thick-walled seamless steel pipe are welded. The water-cooling ring 4 is used to cool the feeding nozzle to install the seat plate. The water-cooled reinforcement ring 5 rolled from steel thick-walled seamless steel pipe is welded, and the water-cooled reinforcement ring 5 is welded to th...

Embodiment 2

[0020] Same as Example 1, the difference is: heat-resistant concrete adopts high aluminum powder, 446 type stainless steel fiber reinforced heat resistant concrete, high temperature resistant aggregate, three sodium phosphate, the first three (high aluminum powder, 446 type stainless steel fiber Reinforced heat-resistant concrete, high-temperature-resistant aggregate) according to the ratio of 1:1.5:2.5 (weight ratio), after mixing evenly, add 15% of its weight of trisodium phosphate, and add an appropriate amount of water to mix evenly, and then directly pour it into the formwork, Use a vibrating pump to vibrate it to make it full, and it will be put into use 36 hours after it is fully formed.

Embodiment 3

[0022] Same as Example 1, the difference is: heat-resistant concrete adopts high aluminum powder, 446 type stainless steel fiber reinforced heat resistant concrete, high temperature resistant aggregate, three sodium phosphate, the first three (high aluminum powder, 446 type stainless steel fiber Reinforced heat-resistant concrete, high-temperature-resistant aggregate) according to the ratio of 1:2.5:3.5 (weight ratio), after mixing evenly, add 15% of its weight of trisodium phosphate, and add an appropriate amount of water after stirring evenly, and then directly pour it into the formwork, Use a vibrating pump to vibrate it to make it full, and it will be put into use 36 hours after it is fully formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com