Photolithographic system and method for measuring deviation between variable gap of photolithographic system and center of mask stage

A technology of lithography system and mask table, which is applied in the measurement field of lithography system and its variable slit and mask table center deviation, which can solve the problem of inaccurate description of relative deviation, low measurement accuracy, and increased measurement cost, etc. Problems, to achieve the effect of low cost, high measurement accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

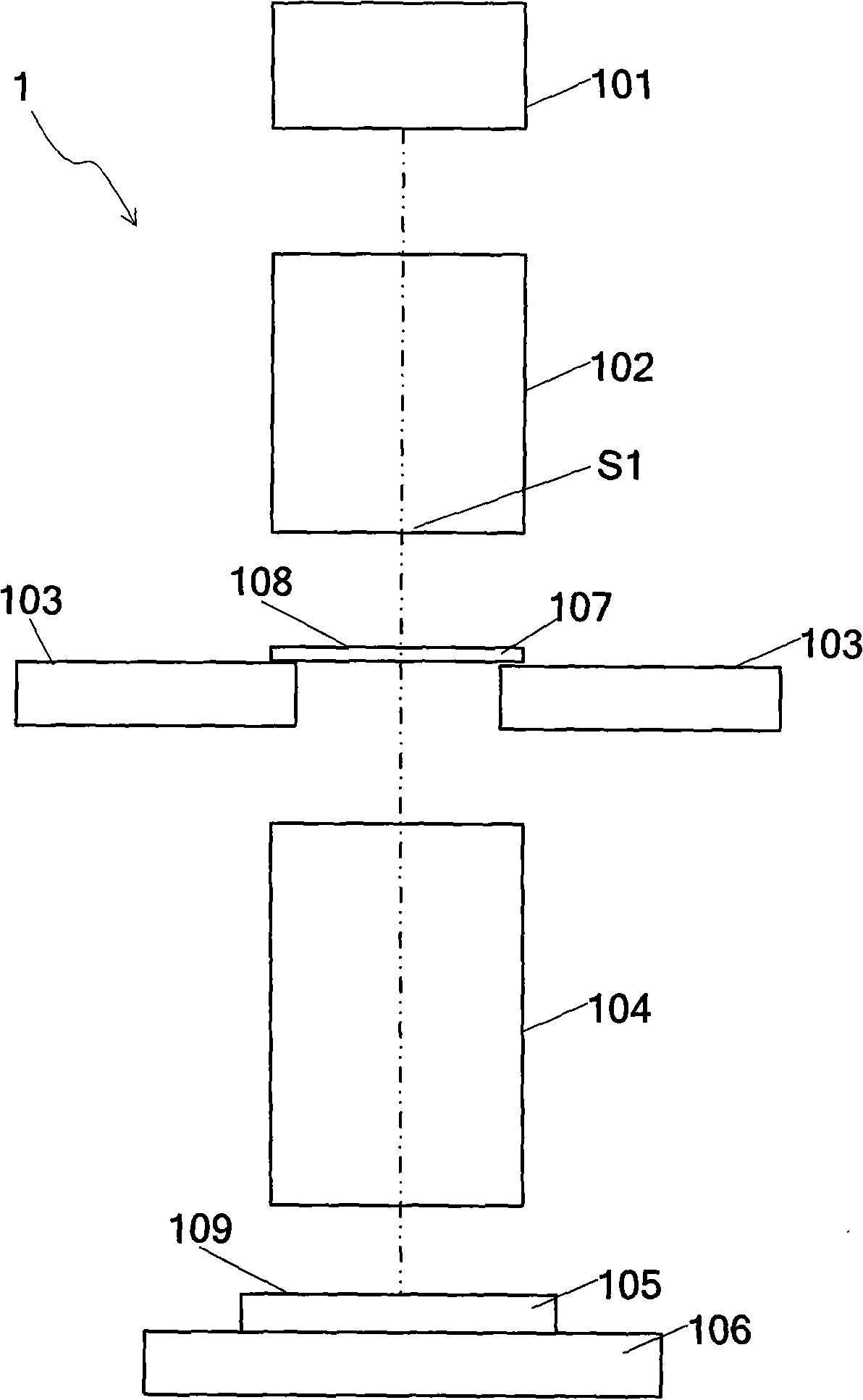

[0017] figure 1 A schematic diagram of a photolithography system according to a first embodiment of the present invention is shown. Such as figure 1 As shown, the lithography system 1 includes a light source 101 , an illumination system 102 with a variable slit S1 , a mask table 103 , a projection objective lens imaging system 104 , a wafer 105 and a table 106 for supporting and fixing the wafer. The photolithography system 1 also includes a reticle 107 . The reticle 107 is set on the mask table 103, and the reticle 107 includes a characteristic pattern 108 for identifying position deviation, and the characteristic pattern 108 forms an image 109 on the wafer 105 through the projection objective lens imaging system, by figure 1 It can be seen that the center of the reticle 107 coincides with the center of the mask table 103 .

[0018] In this embodiment, the light source 101 is a laser light source. The surface of the wafer has photoresist. In addition, in this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com