GU24 pushing-handle switch lamp base

A GU24 and push handle technology, applied in the field of lamp holders, can solve problems such as inconvenient replacement of wires, movement of electrode contact pieces, and influence on the electrical connection of lamp holders, and achieve the effect of simple structure, few connection points, and small quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] Below in conjunction with accompanying drawing, the specific embodiment of the name of the present invention is described in further detail:

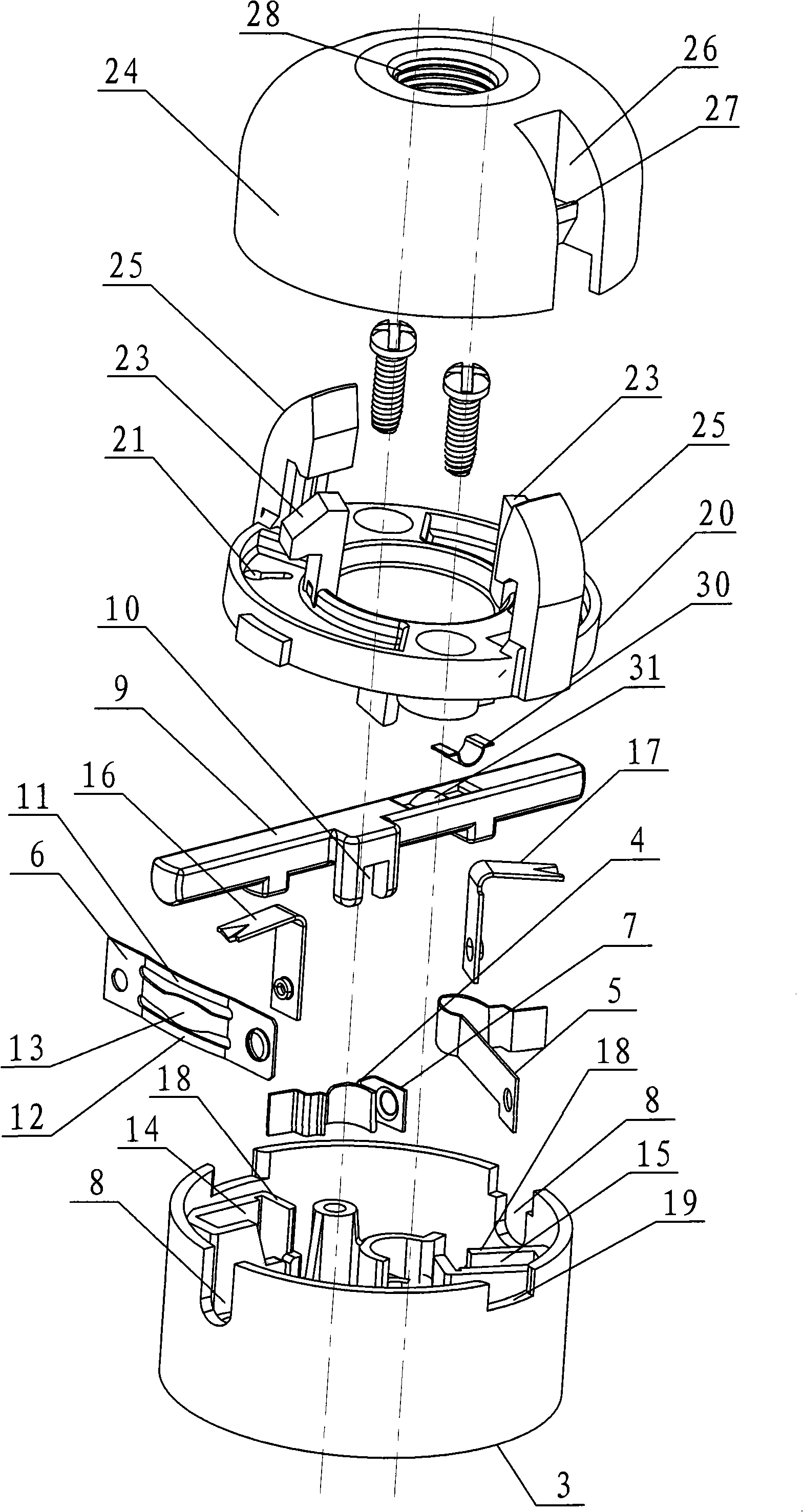

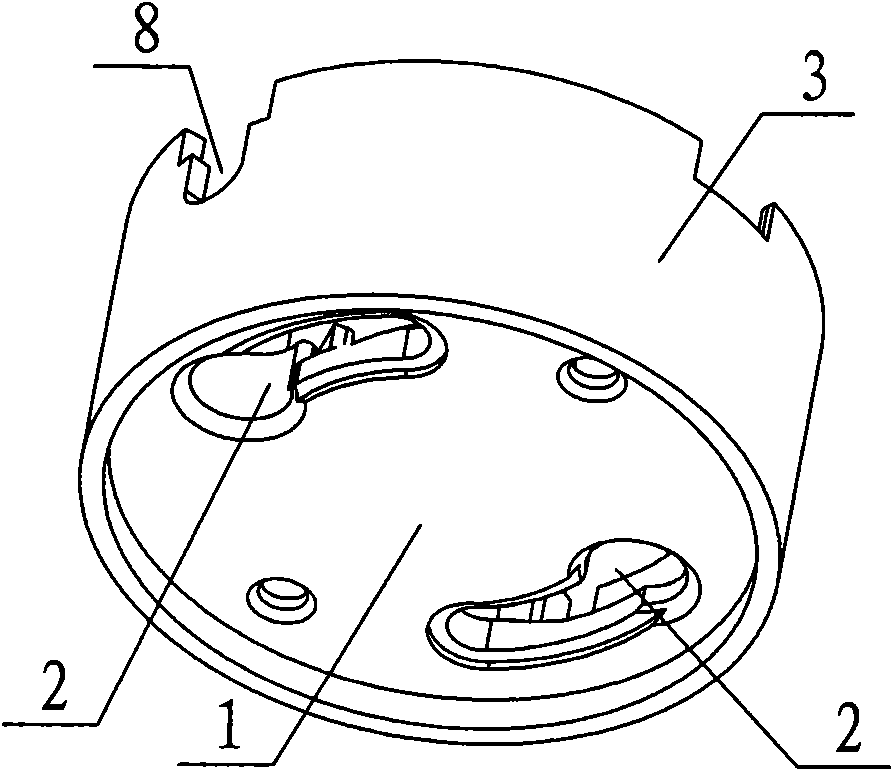

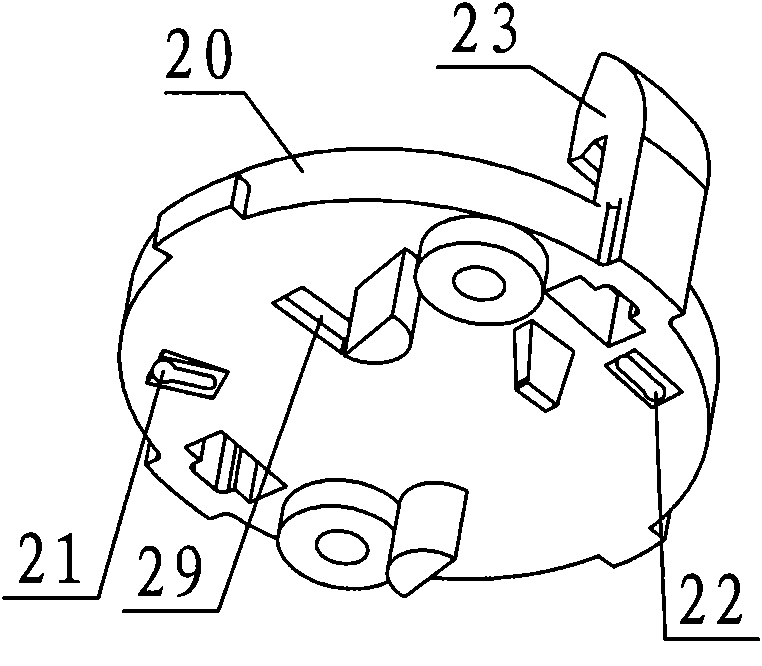

[0016] As shown in Figures 1, 2, 4, and 5, the GU24 push handle switch lamp socket of the present invention includes a cylindrical seat shell 3, and symmetrically arranged on the front baffle 1 of the seat shell 3 The two arc-shaped slot holes 2 are respectively provided with two first electrode contact pieces 4 and second electrode contact pieces 5 beside the slot holes 2 on the inner side of the front baffle 1. The baffle 1 is provided with a movable contact piece 6, and the movable contact piece 6 is made of phosphor bronze and has good elasticity. The first electrode contact piece 4 is provided with a fixed contact piece 7 , the seat shell 3 is provided with a slot 8 , and a push rod 9 is arranged in the slot 8 , and the push rod 9 is A card slot 10 is provided, and the card slot 10 is clipped on the movable contact piece 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com