Magneticflux-switching type composite excitation transverse-magneticflux wind powered generator

A technology of wind power generator and mixed excitation, which is applied to the static parts of the magnetic circuit, the rotating parts of the magnetic circuit, and the shape/style/structure of the magnetic circuit. It can achieve the effect of increasing the torque density, improving the utilization rate and shortening the invalid length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

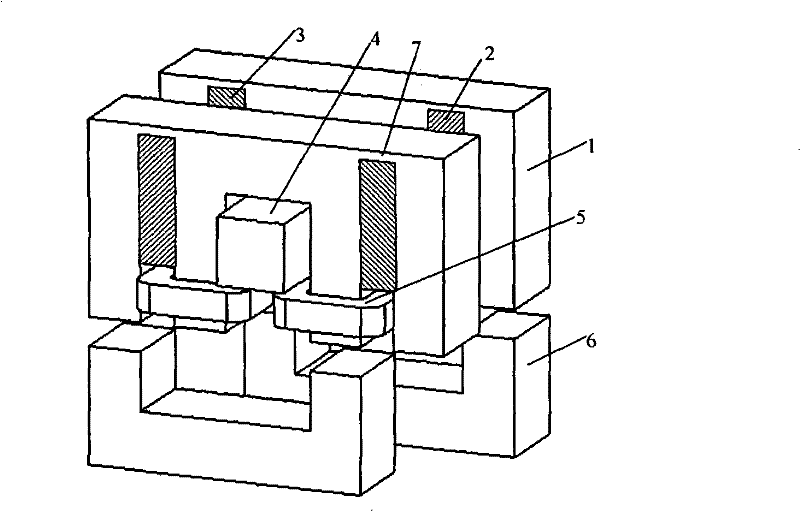

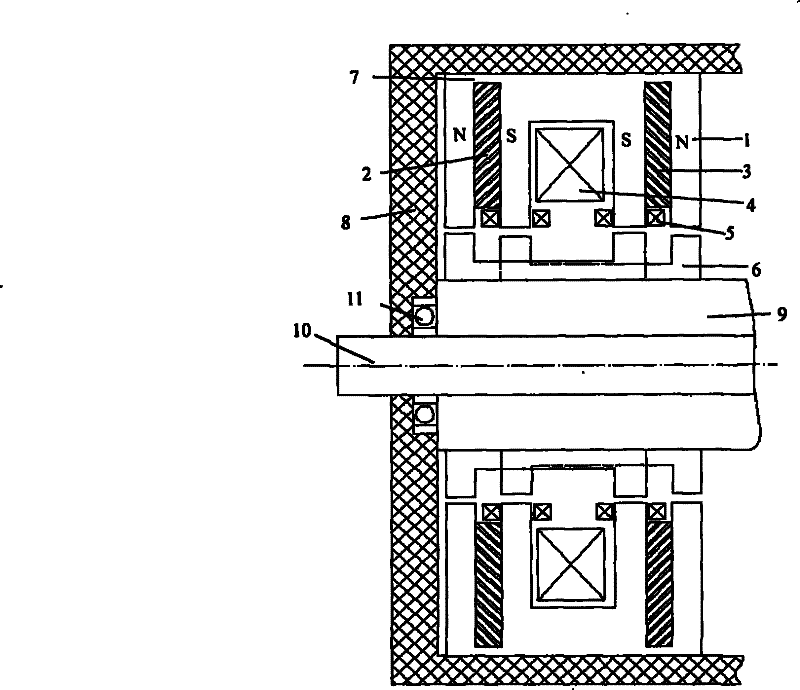

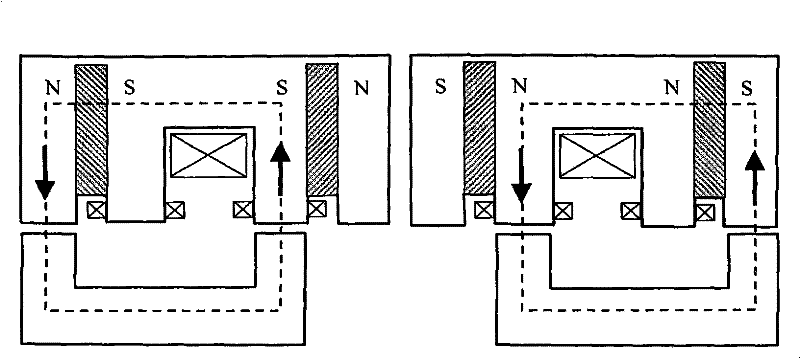

[0018] The magnetic flux switching hybrid excitation transverse magnetic ventilation power generator of the present invention is composed of a stator and a rotor. In order to make better use of the space utilization of the transverse magnetic flux, a permanent magnet with opposite magnetic poles is embedded at both ends of the stator core. The magnetization directions of the permanent magnets in the two adjacent stator cores of each phase are opposite. There is a magnetic bridge at the upper end of the magnet, the armature winding is placed in the stator, and the electric excitation winding is placed in the stator tooth. Each stator core is made of silicon steel sheets, and the size is the same. Inside, the stator is formed as a whole. The permanent magnet in the stator core is made of NdFeB material.

[0019] Each rotor core is only stacked with silicon steel sheets. The structure is simple. The size of each rotor core is the same. The two adjacent rotor cores of each phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com