Electric driver

A nail gun and nailing technology, applied in the field of nail guns, can solve the problem of difficulty in obtaining impact force, and achieve the effect of large friction force and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

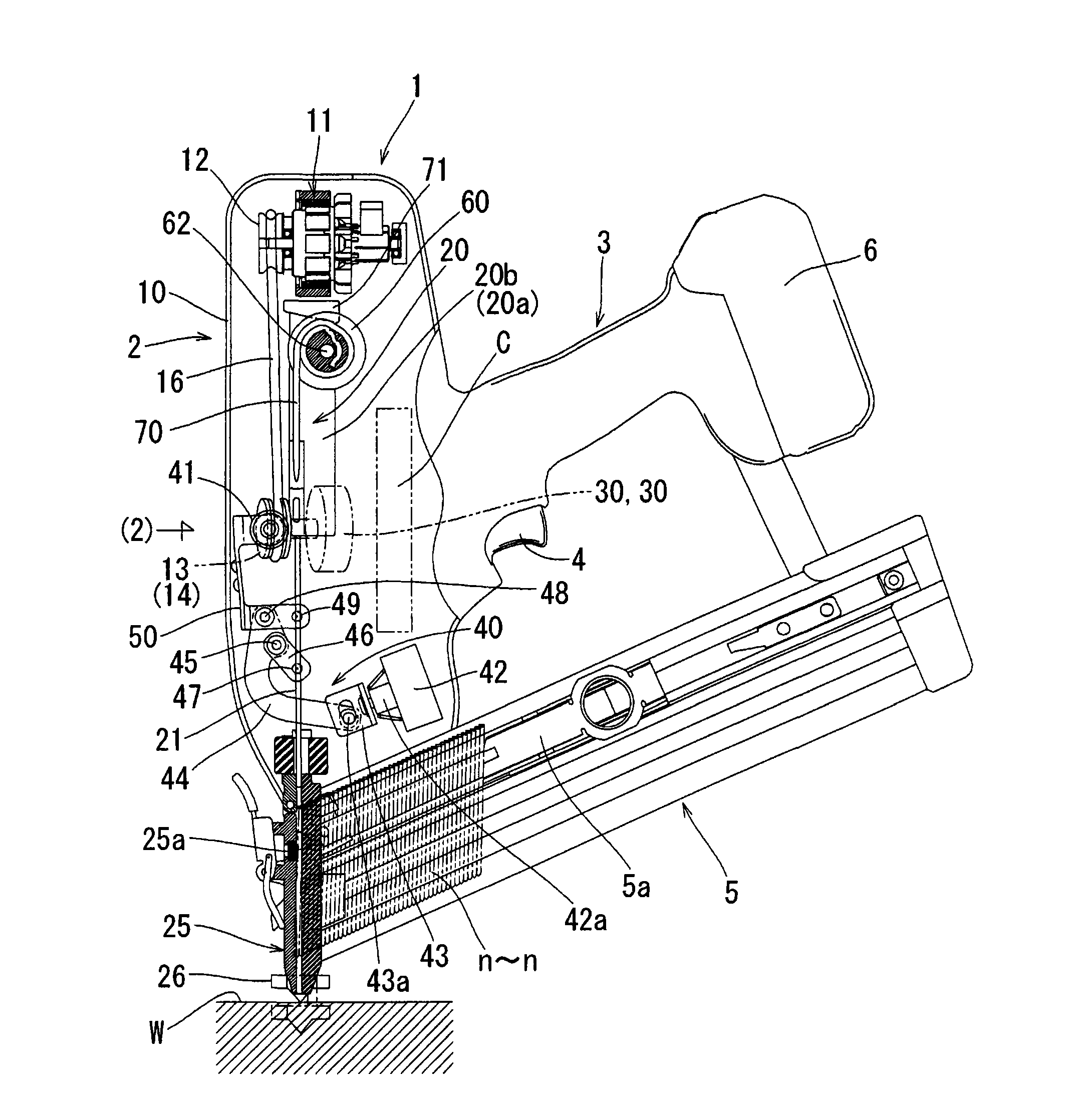

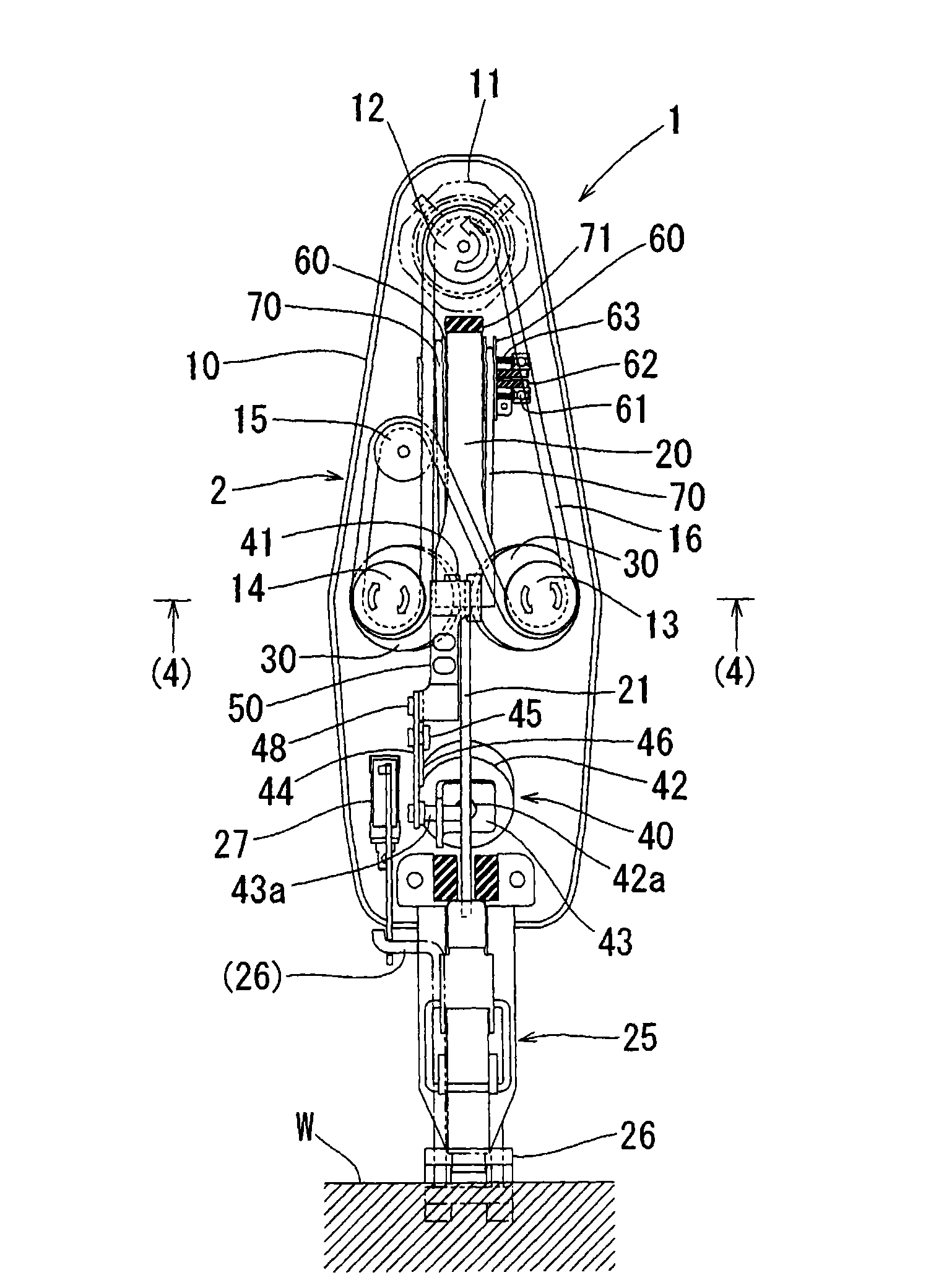

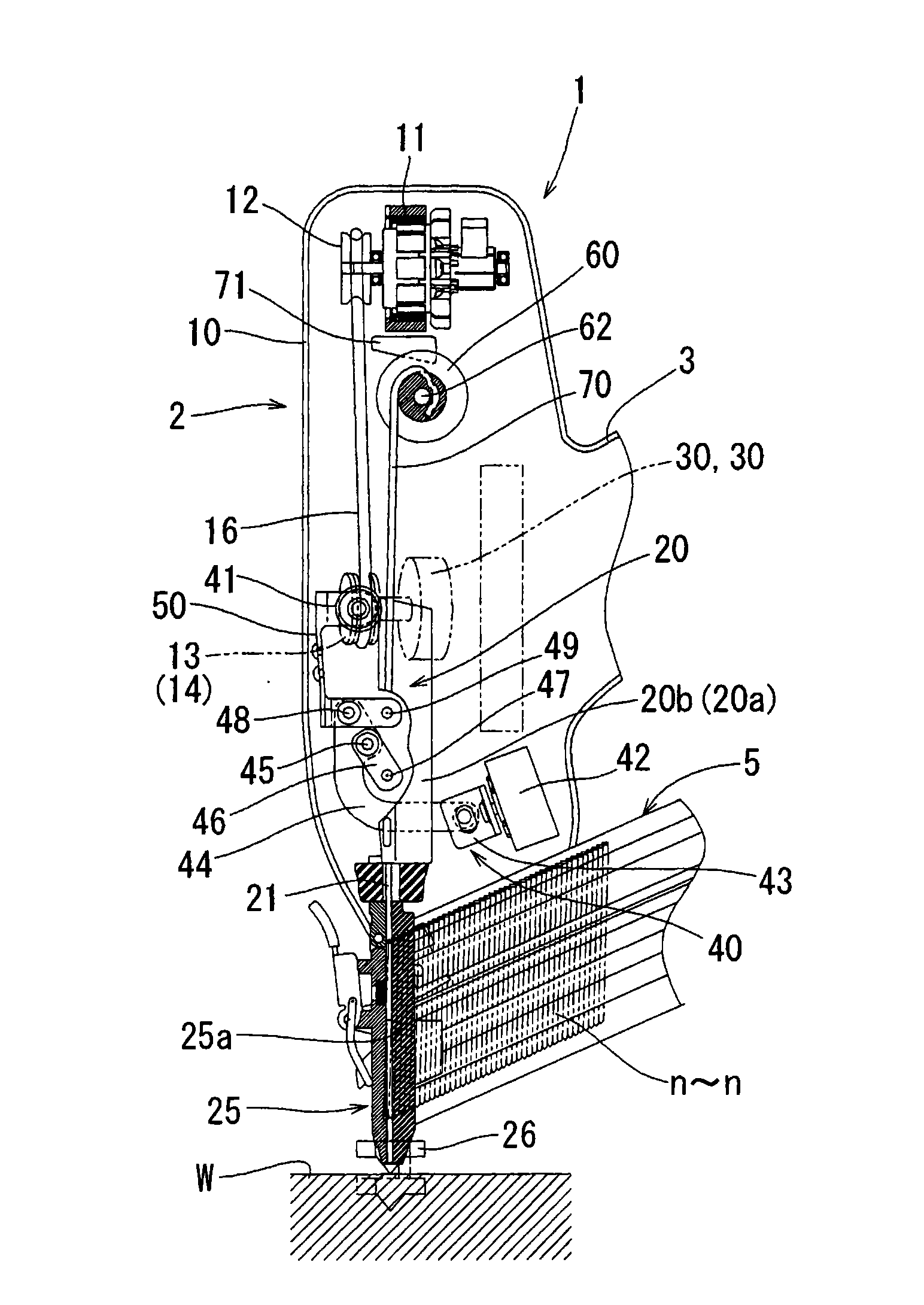

[0040] Below, refer to Figure 1 to Figure 17 Embodiments of the present invention will be described. Figure 1 ~ Figure 3The nail gun 1 of the first embodiment is shown. The nail gun 1 can be roughly divided into a body 2 and a handle 3 . The handle 3 is integrated with the body 2 and protrudes outward from the side of the body 2 . The base of the handle 3 is provided with a trigger switch lever 4 . A nail bin 5 is installed between the fuselage 2 and the handle 3, and the nail bin 5 is in a state spanning between the body 2 and the handle 3, and accommodates a plurality of nailing parts (a nail n is illustrated in this embodiment). ~n). The nail gun 1 of the present embodiment is characterized by a mechanism for driving a nail n which is a nail n. The handle 3 and the staple cartridge 5 are the same as the existing structures, and there is no special change in this embodiment, so the detailed description and illustration thereof are omitted.

[0041] figure 1 Indicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com