Steel wire for spring excellent in fatigue property and drawing property

A fatigue characteristic and wire drawing technology, applied in the direction of spring/shock absorber, coil spring, furnace type, etc., can solve the problem of not necessarily satisfying, and achieve the effect of preventing embrittlement, excellent fatigue characteristic, excellent strength and wire drawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

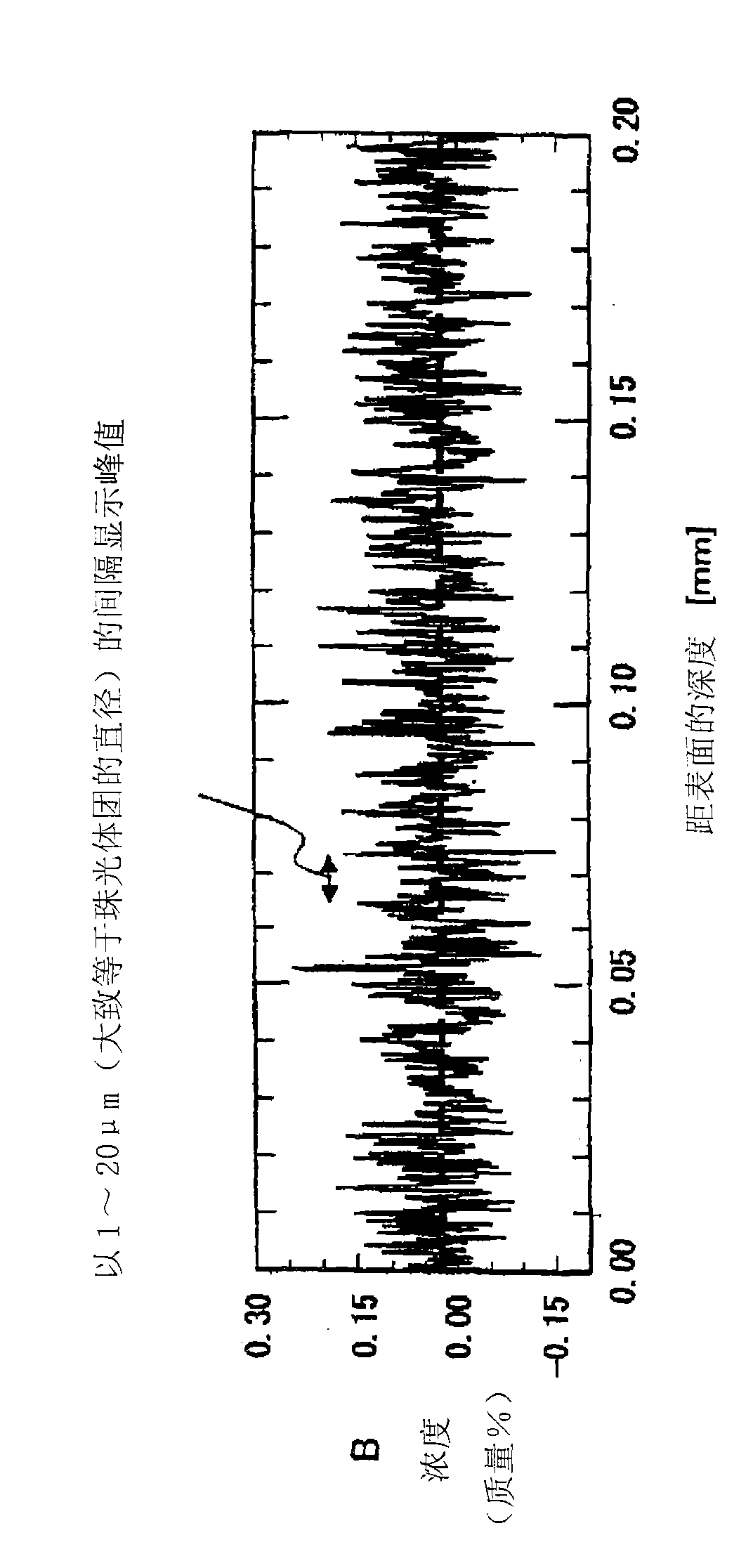

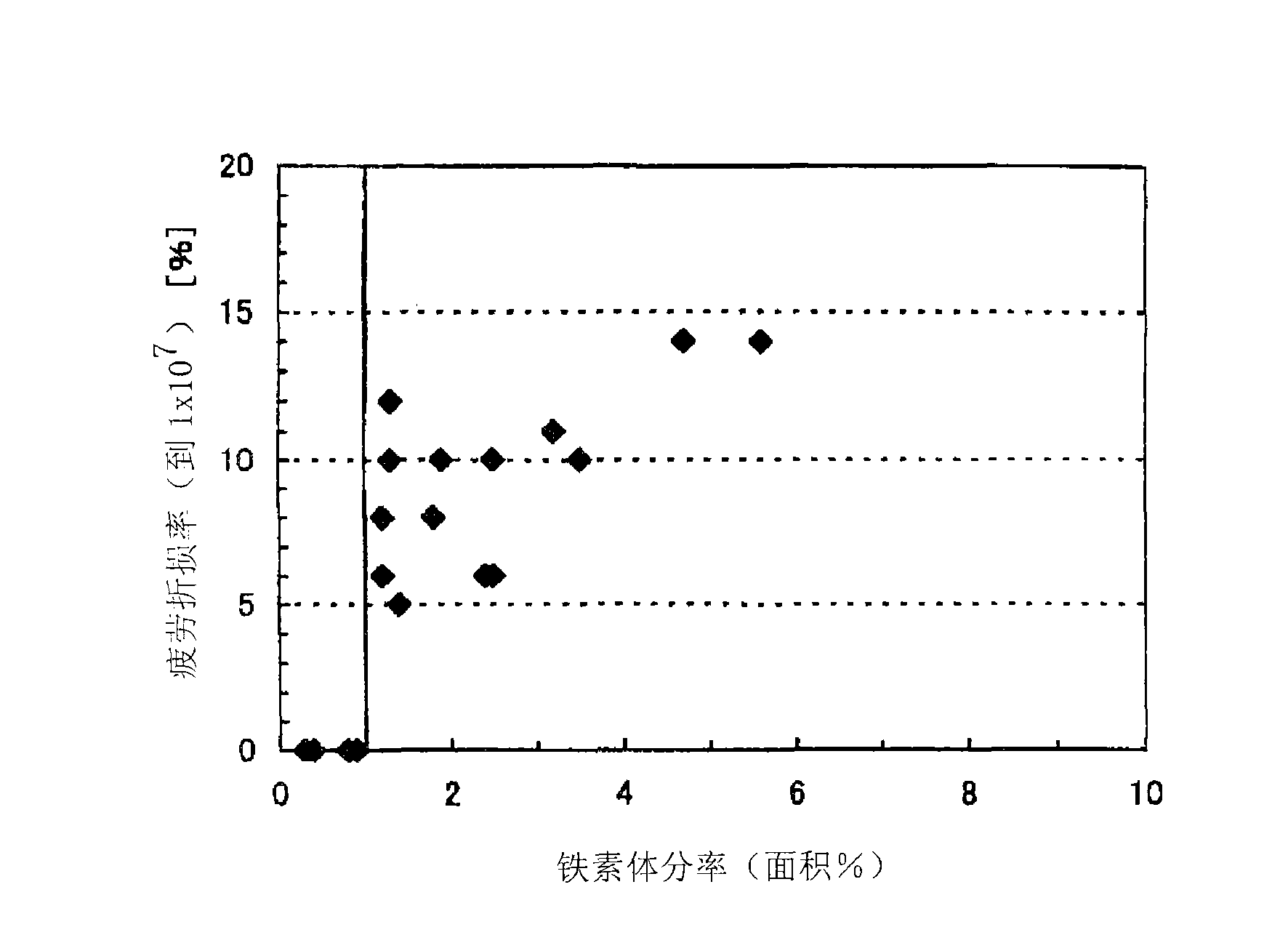

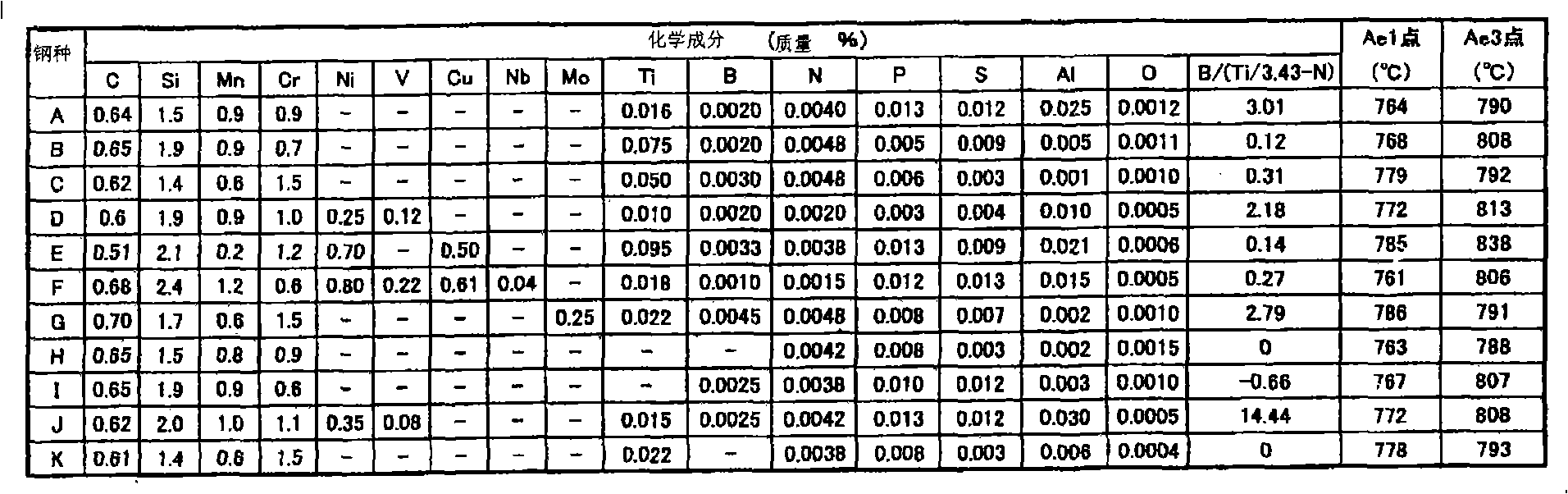

[0097] The steels (steel grades A to K) with the chemical compositions shown in Table 1 were melted in a small vacuum furnace and cast, then cooled at the cooling rate shown in Table 2, and then hot forged to obtain rods with a side of 155 mm. Next, hot rolling was performed under the rolling conditions shown in Table 2 to obtain a steel wire rod with a diameter of 9.0 mm, and then peeled and cut to adjust the diameter to 8.4 mm, and then lead quenching was performed under the conditions shown in Table 2 Afterwards, wire drawing was carried out until the wire diameter shown in Table 2 was obtained to obtain a wire drawing material (steel wire).

[0098] Specifically, in the above-mentioned lead quenching process, as shown in Table 2, the austenitizing heating temperature and heating retention time were changed, and the cooling rate (line speed) was adjusted to vary the lead quenching time for each kind of steel (lead passage time of the line in the bath). The temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap