A same-layer lacquered wooden floor production process and products produced thereby

A production process and wood floor technology, which is applied to wood processing appliances, manufacturing tools, floors, etc., can solve problems such as arching, deformation, inability to effectively waterproof, heat and cold, and improve adhesion and wear resistance. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

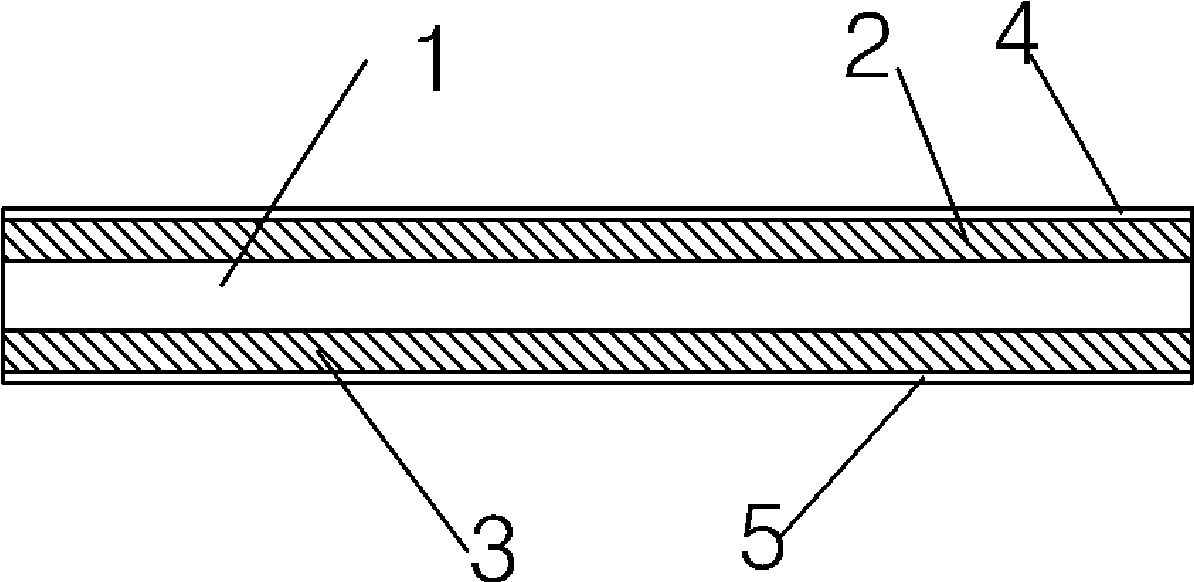

[0016] Example. The production process of the same layer of lacquered wood flooring comprises the steps of assembling the base plate, the surface plate and the bottom plate after gluing the base plate, the surface plate and the base plate by conventional processes, and it is characterized in that it also includes the following steps: performing health preservation on the assembled wooden floor, and the health preservation time is After 7 days, product A is obtained; the upper and lower surfaces of product A are sanded to obtain product B; the upper and lower surfaces of product B are subjected to the same multi-pass painting process, that is, the same paint, the same upper The paint process and the same number of times of painting form a paint layer with the same thickness to obtain a finished product.

[0017] In this example, the structure of the same-layer lacquered wood floor prepared by the above-mentioned process is shown in the attached figure 1 As shown, its compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com