High-temperature hydrothermal synthesis method of phosphorus Al-Si SAPO-34

A SAPO-34, high-temperature hydrothermal technology, applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of reduced catalytic effect, large particle size, etc., and achieve effective control of crystal grains and crystallization The effect of shortening the time and making the crystal grains smaller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Al(OH) in molar ratio 3 : 2H 3 PO 4 : 1SiO 2 :2R:500H 2 O mixed pseudo-boehmite, phosphoric acid, white carbon black and diethylamine raw materials. Mix and stir evenly, seal and heat in an oven at 255°C for 12 hours. After suction filtration, drying, and calcination at 600°C for 24 hours in an air atmosphere in a muffle furnace, the SAPO-34 material can be obtained. The grain size of SAPO-34 is 1-2 microns, and the product yield is 95%.

Embodiment 2

[0022] Al(OH) in molar ratio 3 : 0.3H 3 PO 4 : 0.1 SiO 2 :0.5R:10H 2 O mix aluminum isopropoxide, phosphoric acid, methyl orthosilicate and 2:1 diethylamine and triethylamine raw materials. Mix and stir evenly, seal and heat in an oven at 300°C for 5 hours. After suction filtration, drying, and calcination at 900°C for 12 hours in an air atmosphere in a muffle furnace, the SAPO-34 material can be obtained. The obtained SAPO-34 grain size is 0.5-1.5 microns, and the product yield is 99%.

Embodiment 3

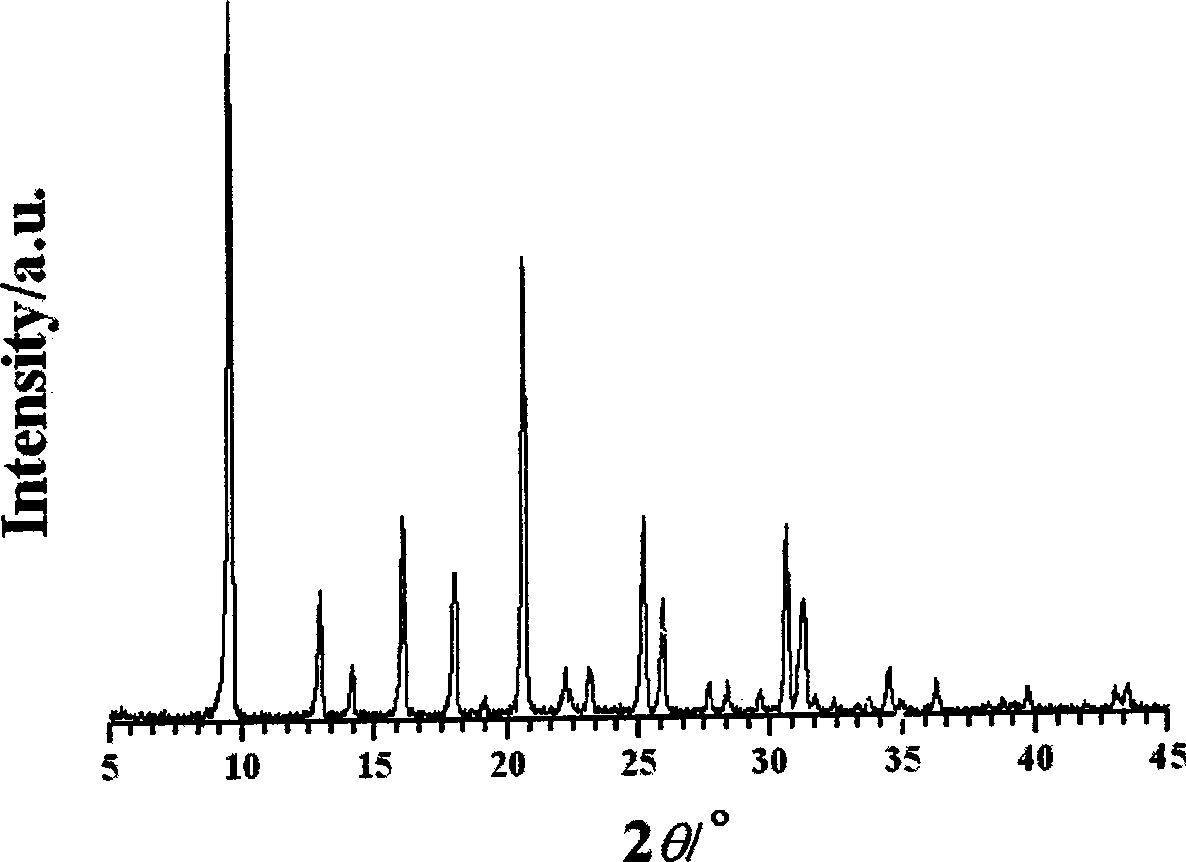

[0024] Al(OH) in molar ratio 3 : 1H 3 PO 4 : 0.5SiO2 2 :1R:100H 2 O mix aluminum isopropoxide, phosphoric acid, silica sol and 4:1 diethylamine and tetraethylammonium hydroxide raw materials. After sealing, heat in an oven at 350°C for 0.2 hours. After suction filtration, drying, and calcination at 400°C for 12 hours in an oxygen atmosphere in a muffle furnace, the SAPO-34 material can be obtained. The product yield was 99%. The XRD and SEM of the obtained SAPO-34 are attached figure 1 and figure 2 shown. from figure 1 It can be seen that the obtained crystals are the pure phase of SAPO-34 without any miscellaneous crystals. from figure 2 It can be seen that the obtained crystals have a size of 2-3 microns and are tetragonal block crystals, which is a typical crystal morphology of SAPO-34.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com