Bar-shaped combination electrode in aluminum foil formation energy-endowing groove and preparation method thereof

A technology of combining electrodes and strip electrodes, applied in the field of electrodes, can solve the problems that the temperature and concentration of the electrolyte cannot be stabilized, and the distribution of the energizing cells cannot be reasonably distributed, so as to improve various properties, improve the structure, and reduce oxygen vacancies. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and specific embodiments.

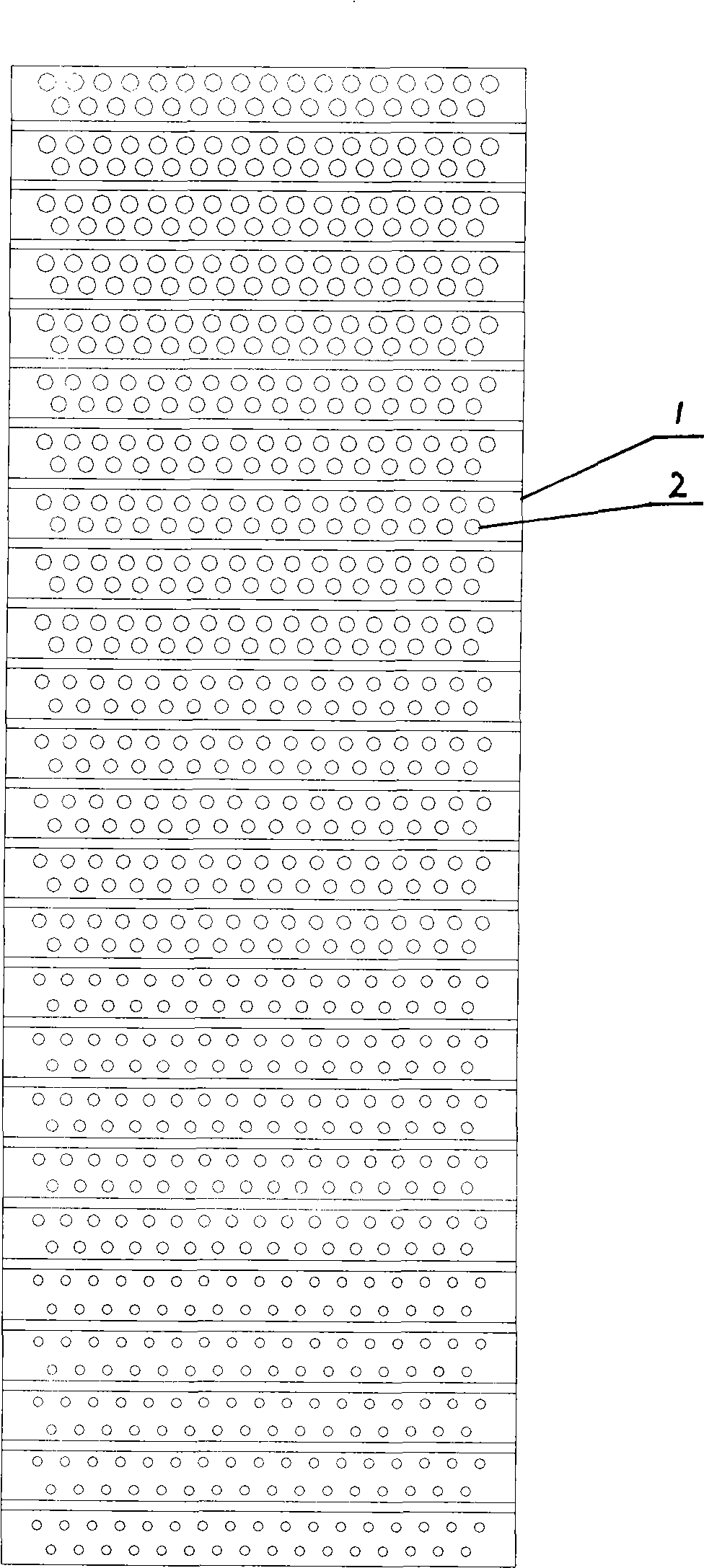

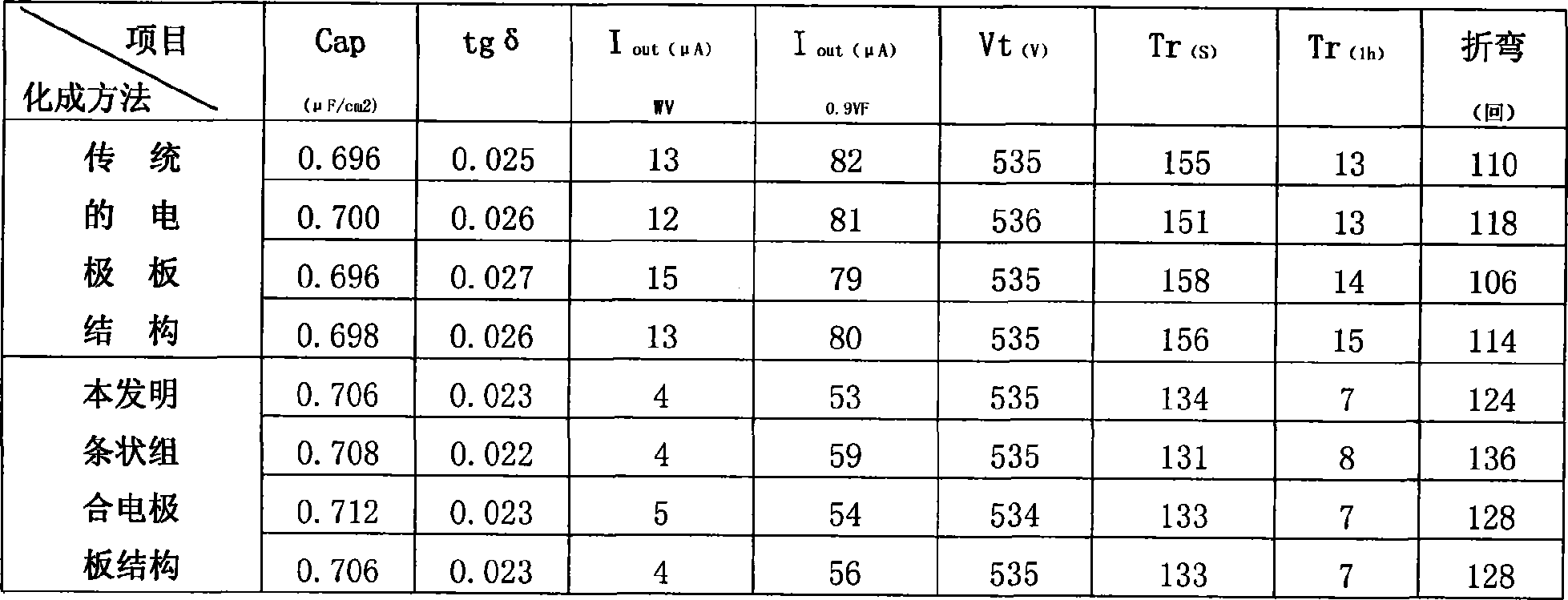

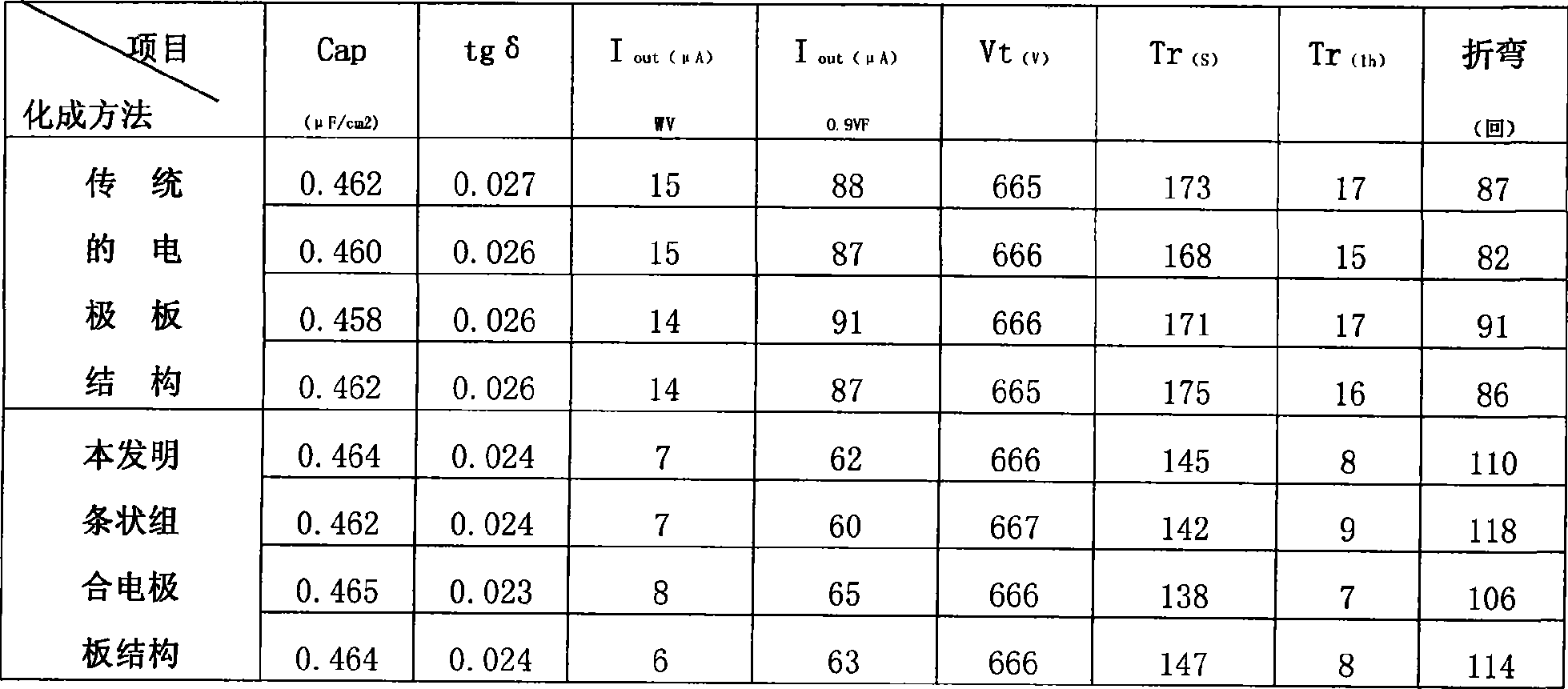

[0013] The strip-shaped composite electrode of the present invention first separates the 1500×520mm electrode plate in the energizing tank into 25 strip-shaped electrode strips 1 of 50×120mm with a spacing of 8-12mm, and the two ends are welded to the stainless steel material like a ladder. According to the distribution law of current density on the aluminum foil, a hole 2 with a diameter of 2-18mm is punched on the strip electrode strip 1 (the larger the current density, the smaller the hole diameter), and the hole of the first composite electrode plate is from the top To the bottom, from large to small, the holes on the adjacent second combined electrode plate from bottom to top, from large to small, forming a combined strip electrode plate, adding electrolyte to the energizing tank, and placing the aluminum foil in the strip shape Between the combined electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com