Device for detecting ash content at coal bypass on line and method thereof

A technology of ash content detection and coal, which is applied in the field of rapid automatic detection devices, can solve the problems of outweighing the gains, the influence of detection instruments, and the inability to use radiation measurement technology, etc., and achieve the effects of low cost, interference elimination, and measurement error elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

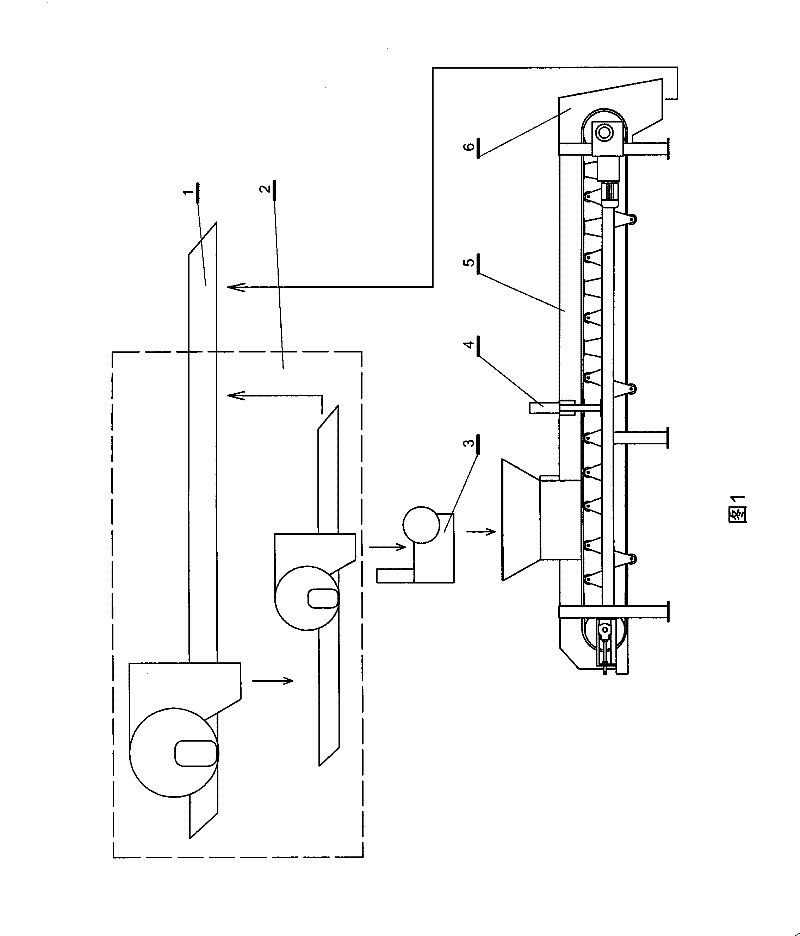

[0020] This embodiment is a coal bypass online ash detection device, such as figure 1 shown. The device includes: a sampling system 2 installed on the main line 1 of the transport coal flow, a crusher 3 connected to the sampling system, a sample regularization mechanism 5 connected to the crusher, installed on the sample regularization mechanism The ultra-low radiation radiation detection instrument 4, and the discarding mechanism 6 connected with the sample regularization mechanism to send the measured coal powder into the main line of transport coal flow.

[0021] The sampling system described in this embodiment may be a sampling system installed directly on the main line of coal transportation, and the collected samples are directly crushed. In actual production, there are usually two stages of sampling. Because the coal on the main line of transport coal flow is very different, one sampling cannot meet the requirements. In order to meet the needs, multiple sampling can ...

Embodiment 2

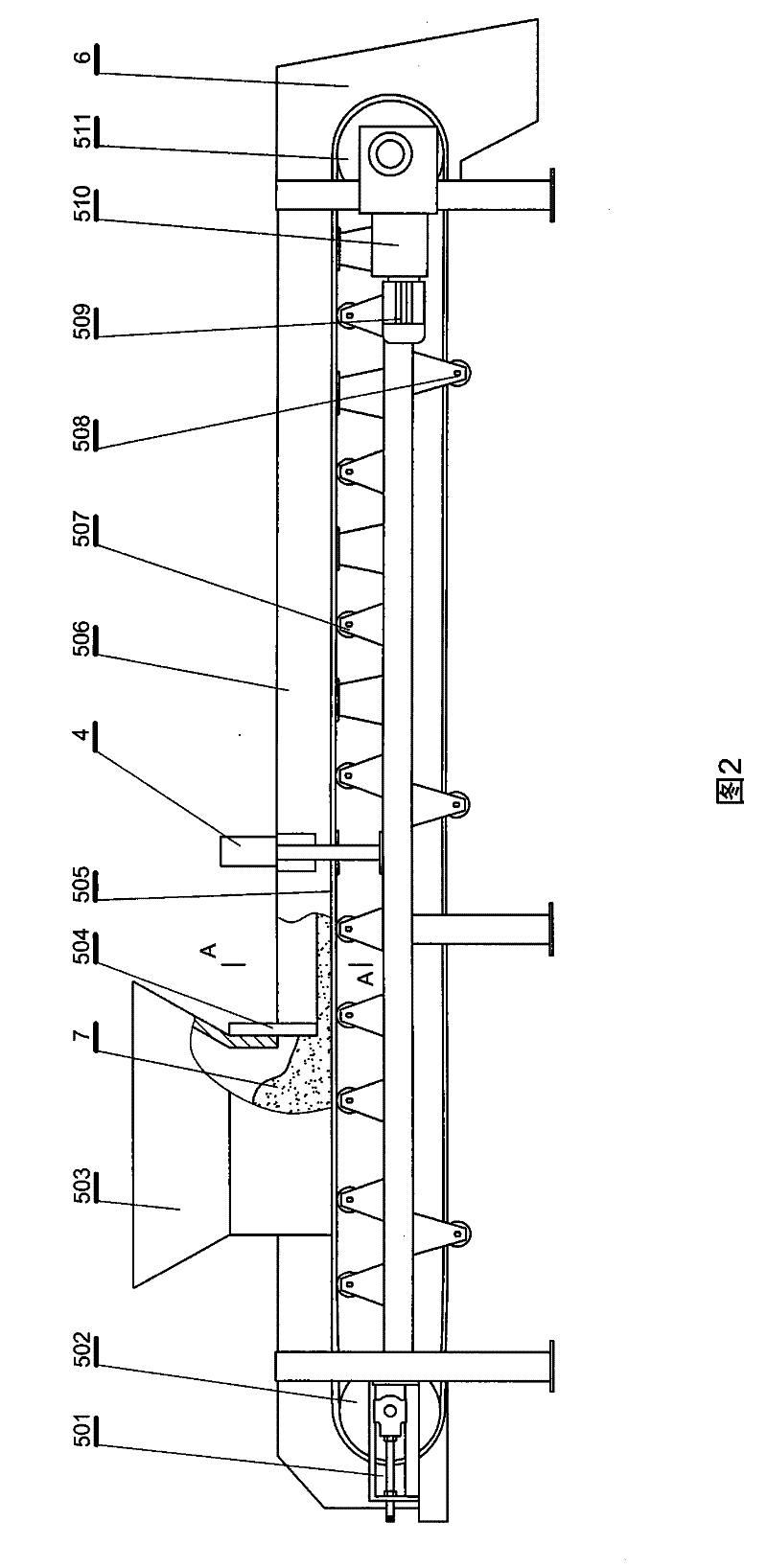

[0026] This embodiment is an improvement of the device described in Embodiment 1, and is a refinement of the sample regularization mechanism, such as figure 2 shown. The sample regularization mechanism described in this embodiment includes: the driving wheel 511 and the driven wheel 502 of the conveying belt installed at both ends of the frame, the conveying belt 505 sleeved on the driving wheel and the driven wheel, and the driving wheel passes through the reducer 510 is connected with the motor 509, the belt tensioning mechanism 501 is housed on the driven wheel, and the upper and lower support pulleys 507, 508 are respectively installed on the upper and lower sides of the conveying belt. A feeding hopper 503 is installed on the conveying belt, side plates 506 are respectively installed on both sides of the conveying belt along the conveying direction, and a scraper 504 is installed at the outlet of the conveying hopper, and the scraper and the scraper are connected to each...

Embodiment 3

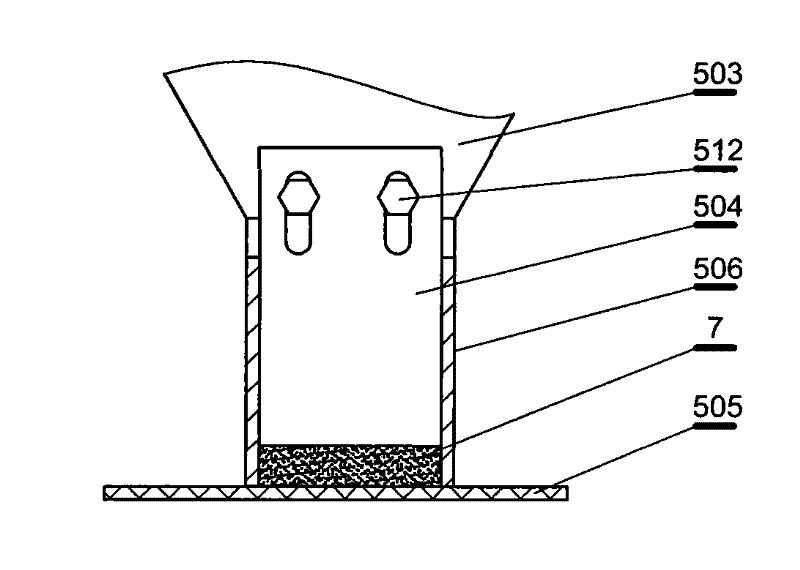

[0030] This embodiment is an improvement of Embodiment 1 or 2, and is a refinement of the scraper of the above embodiment, such as image 3 shown. The scraper described in this embodiment is fixed on the hopper by adjusting bolts 512 .

[0031] In order to adjust the size of the rectangular material outlet, an adjusting bolt is provided in this embodiment. The bolt hole on the scraper plate is a long hole, so that the scraper plate can move up and down by adjusting the bolt, so that the size of the discharge port can be adjusted, and the actual effect changes the height of the strip-shaped test sample with a rectangular cross section to meet the Requirements for various radiation detection instruments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com