Digital multifunctional special fire water supply device controller

A technology for water supply equipment and controllers, applied in electric controllers, controllers with specific characteristics, and program control in sequence/logic controllers, etc., can solve problems such as poor accuracy and reliability, single function, easy "crash" problems, to achieve the effect of improving accuracy and reliability, enriching functional modules, and improving program efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

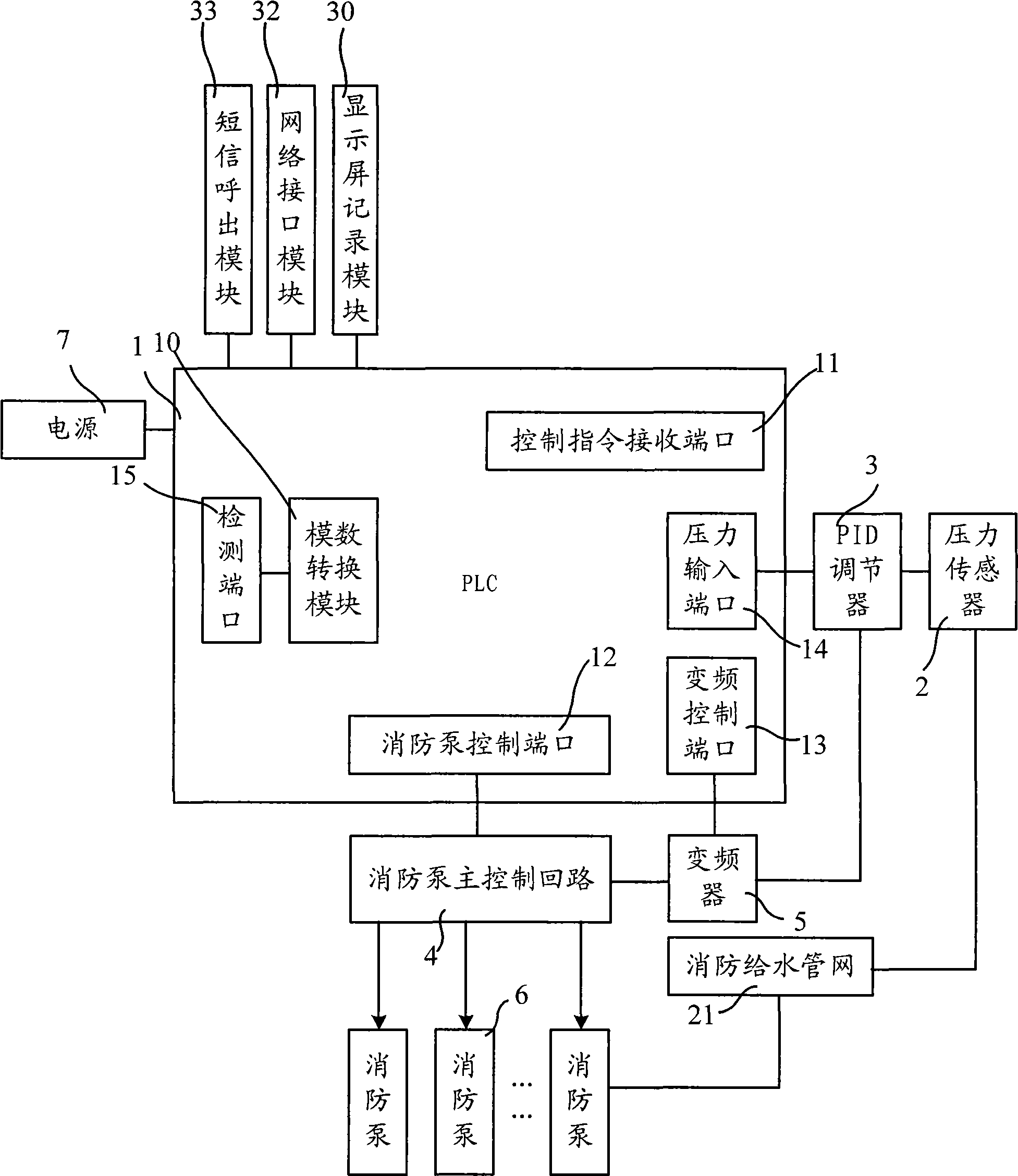

[0021] figure 1 It is a schematic diagram of the structure of the digital multi-functional dedicated fire-fighting water supply equipment controller provided by the first embodiment of the present invention. The fire-fighting water supply equipment controller is a digital controller dedicated to fire-fighting water supply equipment. The structure of the controller includes: PLC 1, pressure The sensor 2 and the PID regulator 3 also include any one or more of the analog-to-digital conversion module 10 , the display screen recording module 30 , the network interface module 32 and the short message calling module 33 .

[0022] Among them, PLC 1 is the core control component of the control system, including arithmetic units and controllers, capable of storing system programs and user programs. The PLC 1 is provided with a plurality of input ports and output ports, specifically including at least a control command receiving port 11 , a fire pump control port 12 and a frequency conve...

no. 2 example

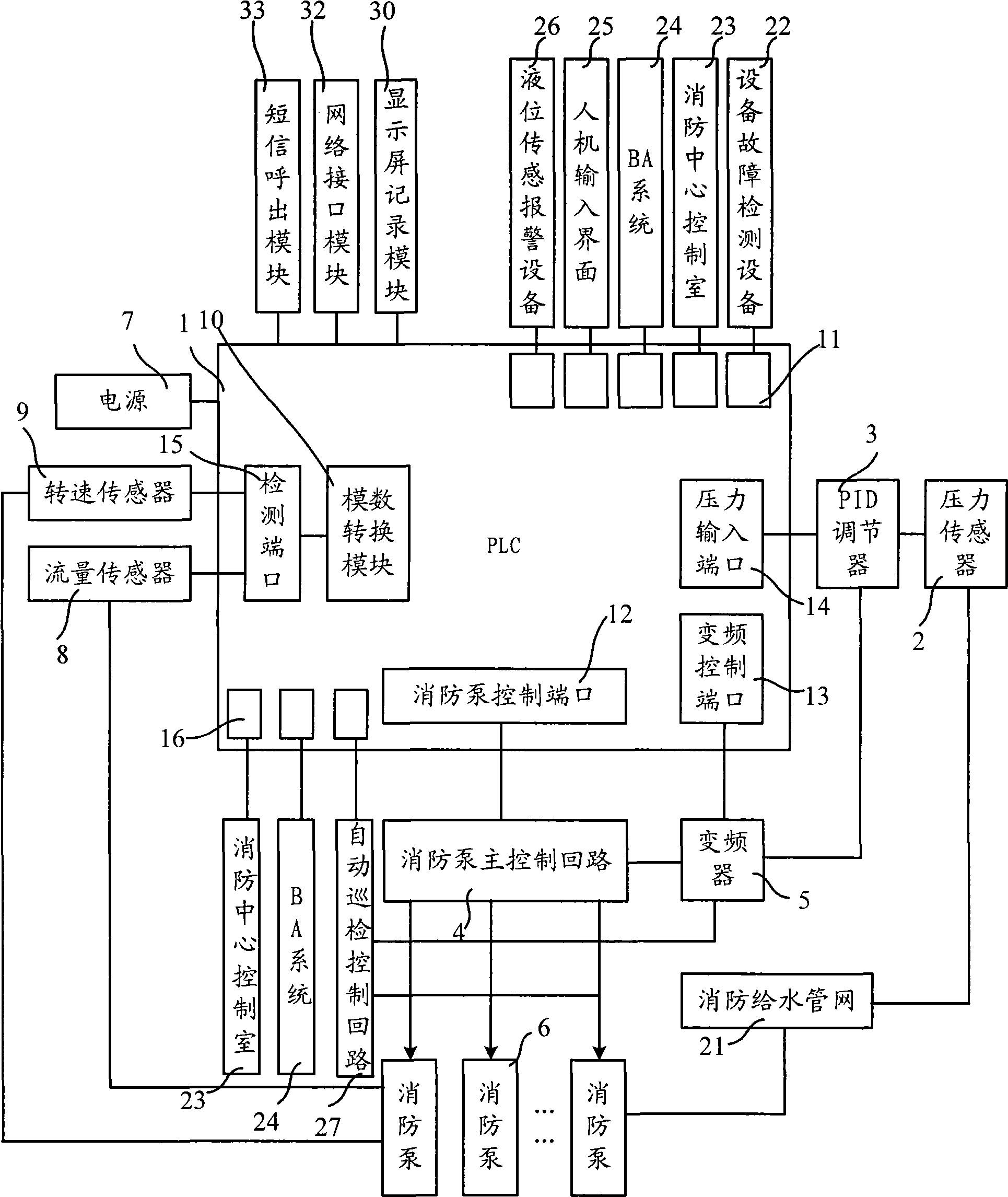

[0032] figure 2 It is a schematic diagram of the structure of the digital multifunctional dedicated fire water supply equipment controller provided by the second embodiment of the present invention. This embodiment can be based on the above-mentioned first embodiment, and further includes a flow sensor 8 and a rotational speed sensor 9 .

[0033]Wherein, the flow sensor 8 is connected to the detection port 15 of the PLC 1 for connecting to the fire pump 6 to detect the flow of the fire pump 6 , and generates a flow signal to be transmitted to the detection port 15 . The rotational speed sensor 9 is connected to the detection port 15 of the PLC 1 for connecting to the fire pump 6 to detect the rotational speed of the motor of the fire pump 6 , and generates a rotational speed signal to be transmitted to the detection port 15 .

[0034] In this embodiment, sensors are added to the digital multifunctional special fire water supply equipment controller, which can enrich the dete...

no. 3 example

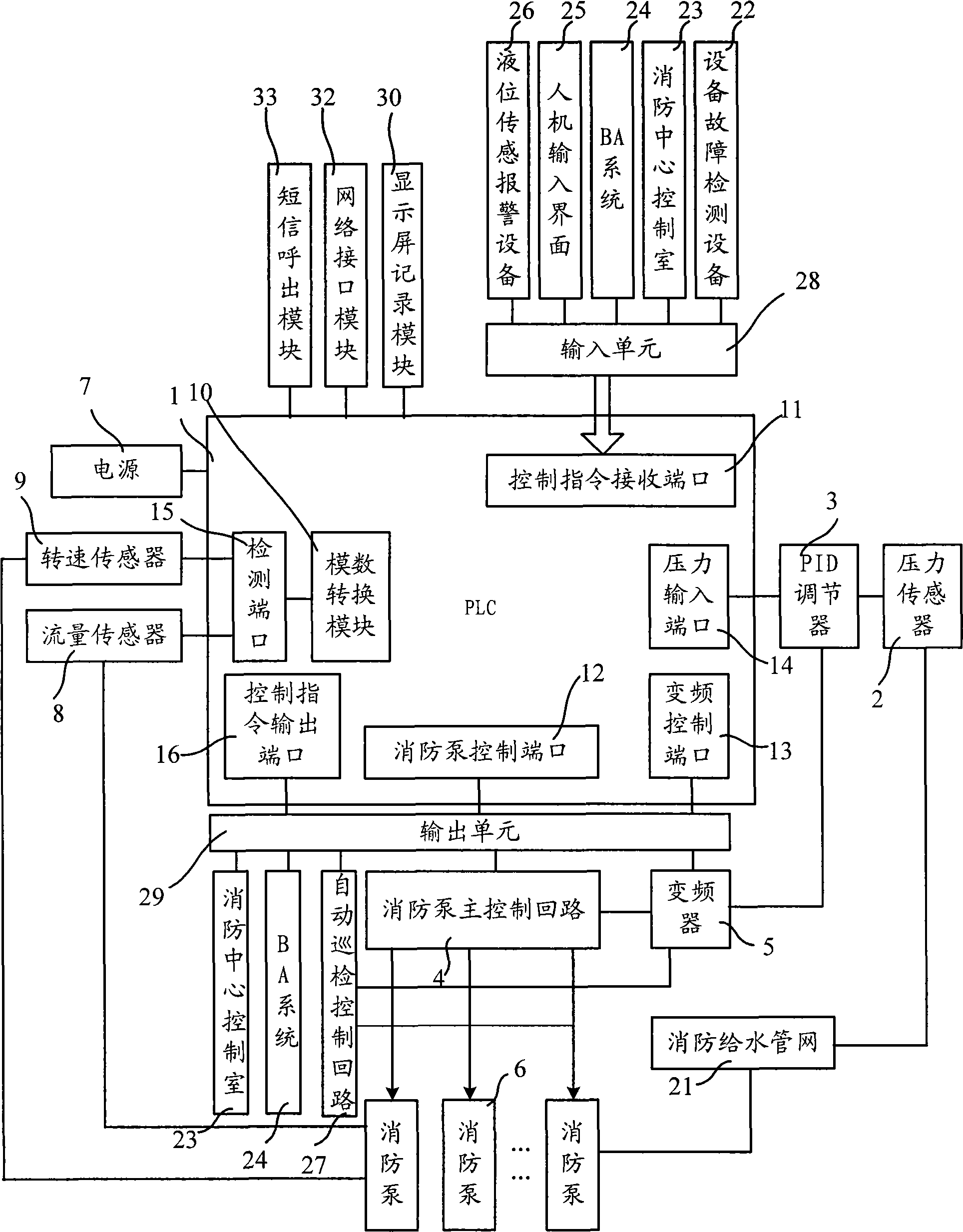

[0045] image 3 It is a schematic diagram of the structure of the digital multifunctional special fire water supply equipment controller provided by the third embodiment of the present invention. This embodiment can be based on the above-mentioned second embodiment, and an input unit 28 and an output unit 29 are further added.

[0046] The input unit 28 includes a plurality of relays, which are respectively connected between each control instruction receiving port 11 and the correspondingly connected equipment, for example, connected to the equipment fault detection equipment 22, the fire control center control room 23, the BA system 24, the man-machine input interface 25 and Between the liquid level sensing alarm device 26 and the control instruction receiving port 11 . The control commands and alarm signals issued by the above-mentioned devices all control the respective connected relays with switching values, and the output terminals of the relays are connected to the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com