Flat display

A flat-panel display, display panel technology, applied in static indicators, instruments, nonlinear optics, etc., can solve the problems that display panels and PCBs cannot use wireless communication, inconvenience, damage maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

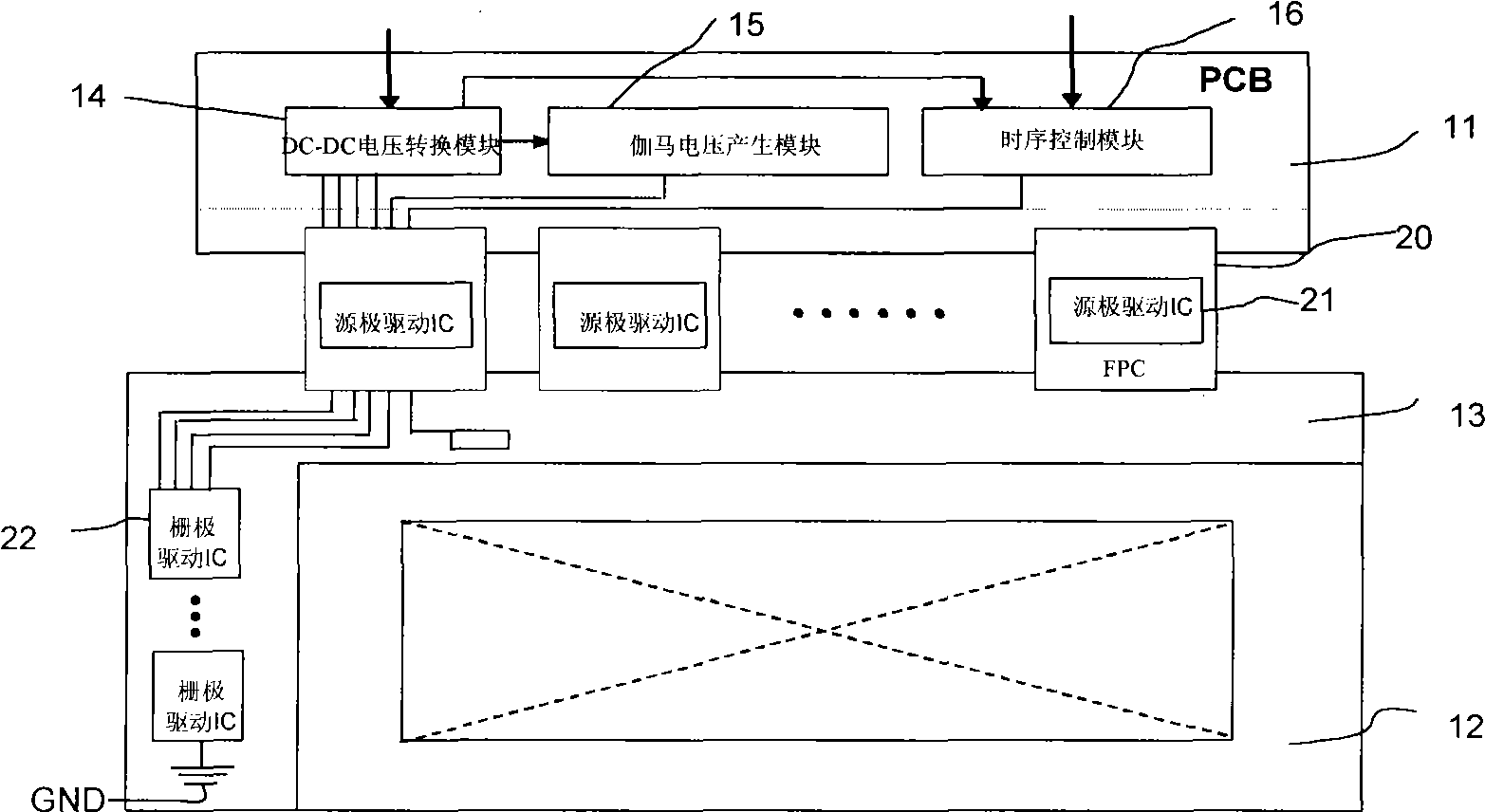

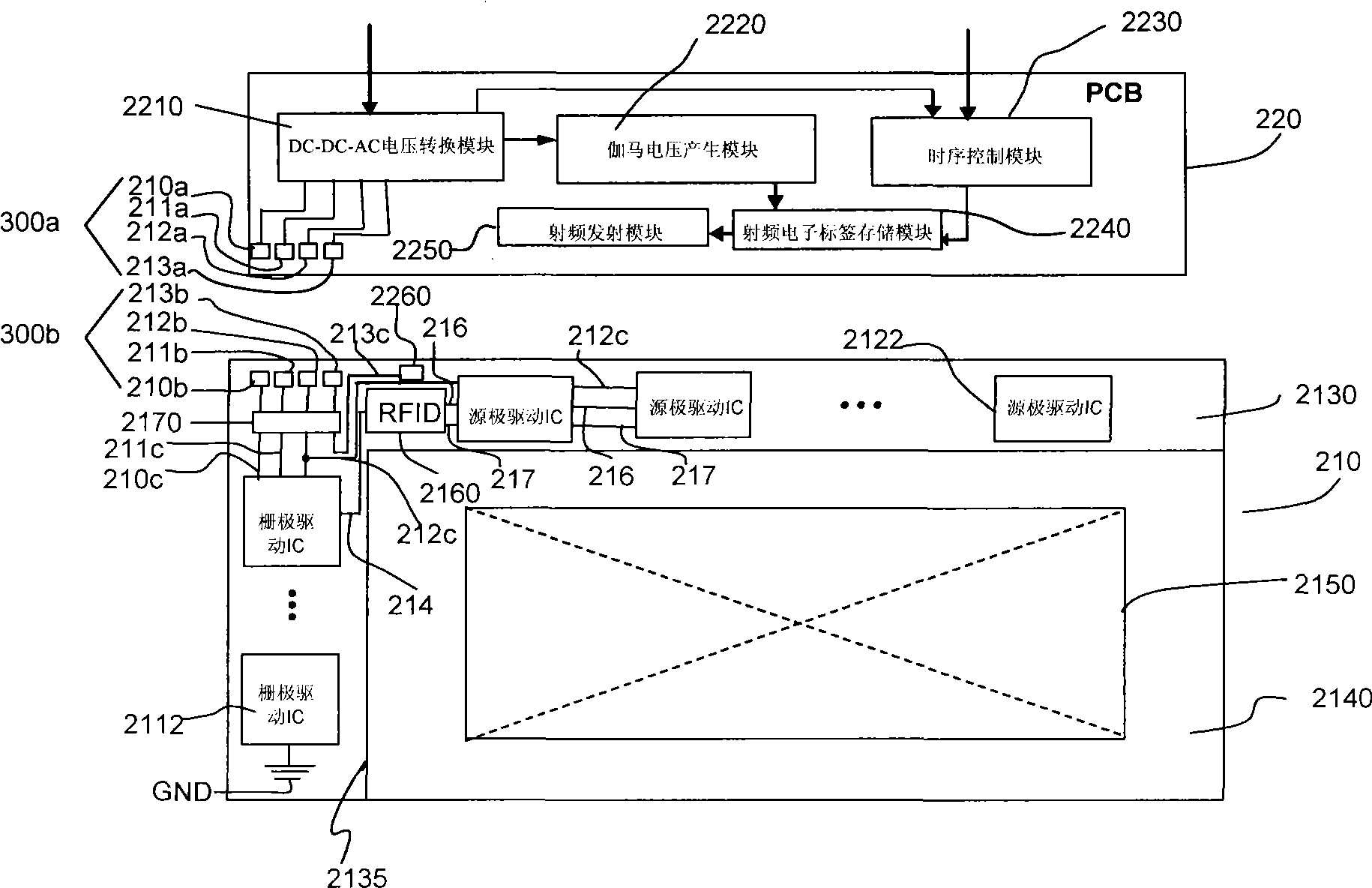

[0056] figure 2 It is a schematic diagram of the connection method between the PCB and the display panel of the first embodiment of the liquid crystal display of the present invention. Such as figure 2 As shown, the liquid crystal display includes: a display panel 210 , a PCB 220 and a wireless signal transmission device, and the wireless signal transmission device is used to realize wireless signal transmission between the PCB 220 and the display panel 210 .

[0057] Wherein, the display panel 210 includes two opposite substrates, that is, a first substrate 2130 and a second substrate 2140 . The gate driving IC 2112 is bonded on the side of the first substrate 2130 facing the second substrate 2140 through COG, and is located beside the display area 2135 , for example, on the left side. The source driver IC 2122 is COG bonded on the side of the first substrate 2130 facing the second substrate 2140 , and is located beside the display area 2135 , for example, above it. Ther...

Embodiment 2

[0093] In the second embodiment, the same part as the first embodiment will not be repeated, the difference is:

[0094] Such as Figure 8 As shown, the data signal transmission module includes a plurality of RFIDs arranged on the display panel, such as RFID 2160a, 2160b, 2160c, 2160d, 2160e, 2160f, and the plurality of RFIDs correspond to the gate drive IC and the source drive IC respectively. Conductive interconnection. Different source driver ICs use their corresponding RFIDs to directly receive signals, and different gate driver ICs use their corresponding RFIDs to directly receive signals. In this embodiment, the data signals corresponding to the corresponding gate driver ICs and source driver ICs are directly supplied through respective RFIDs, so that the stability and speed of data signal transmission are improved.

Embodiment 3

[0096] In the third embodiment, the same part as the first embodiment will not be repeated, the difference is:

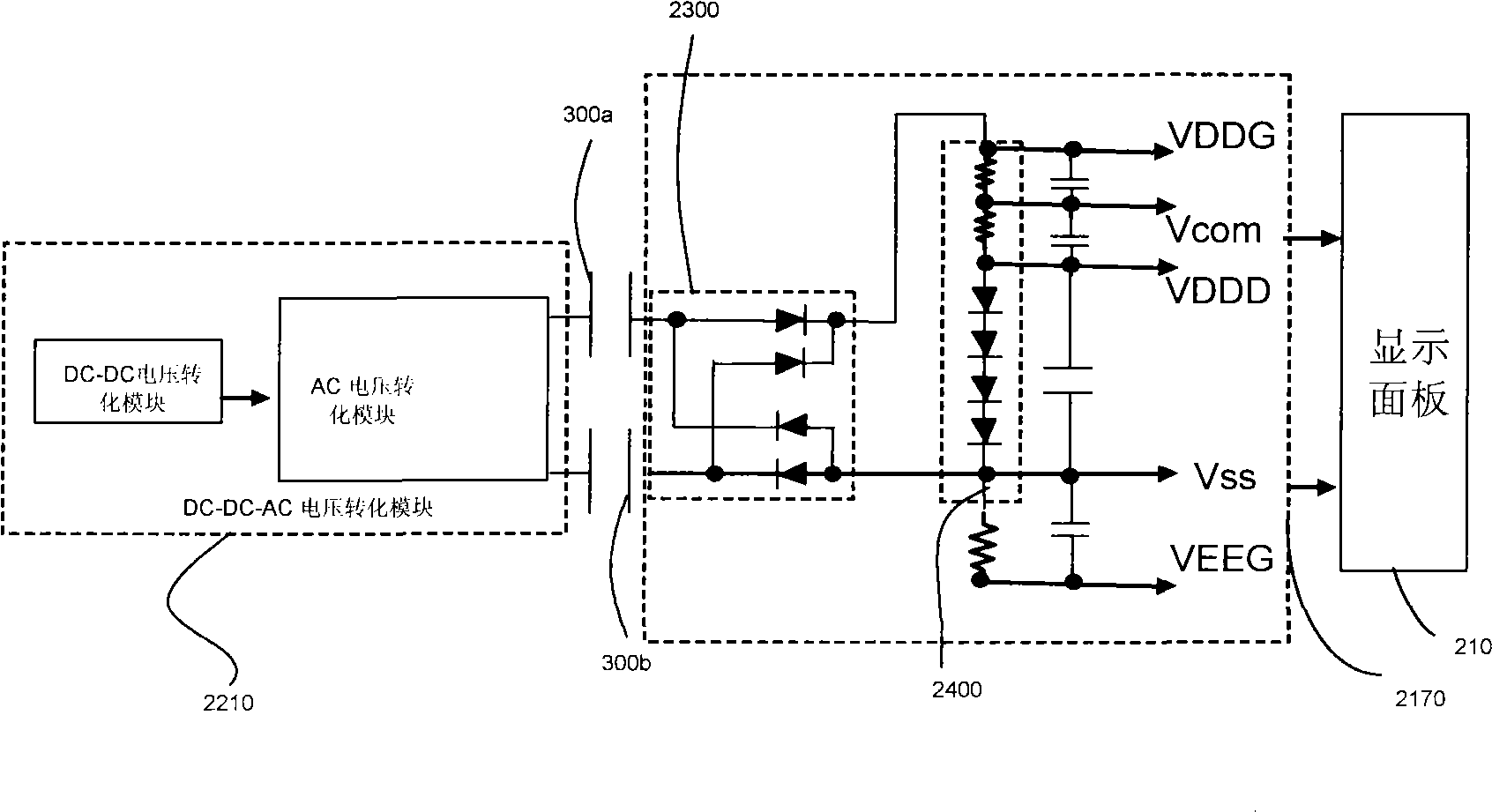

[0097] Such as Figure 9 As shown, the second capacitive coupling electrode 300b is respectively arranged beside the gate drive IC 2112, the source drive IC 2122, the common electrode connection terminal (not shown) and the RFID (not shown), the first capacitive coupling electrode 300a and the second The positions of the capacitive coupling electrodes 300b are in one-to-one correspondence. The liquid crystal display also includes an FPC810, and a gate drive IC side circuit board 820 connected to the PCB220 through the FPC810, a part of the first capacitive coupling electrodes 300a is located on the PCB, and another part of the first capacitive coupling electrodes 300a is located on the gate drive IC side circuit board . The power signal output by the DC-DC-AC voltage conversion module on the PCB is connected to the first capacitive coupling electrode 300a on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com