Refrigerator oil composition

一种冷冻机油、组合物的技术,应用在润滑组合物、石油工业、基料等方向,能够解决没有节能性研究等问题,达到节能性优异、摩擦系数低的效果

Inactive Publication Date: 2009-09-16

IDEMITSU KOSAN CO LTD

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] However, in the refrigerating machine oil composition of the above (1), the main purpose of research is wear resistance and capillary blockage prevention; in the refrigerating machine oil composition of the above (2), the main purpose of wear resistance is studies conducted, none of them studied energy efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~15 and comparative example 1~6

[0181] Prepare the refrigerating machine oil with the composition shown in Table 1, calculate the coefficient of friction, reduction rate of power consumption, and reduction rate of capillary flow rate, and conduct shielded tube test at the same time. The results are shown in Table 1.

[0182]

[0183]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| dynamic friction coefficient | aaaaa | aaaaa |

Login to View More

Abstract

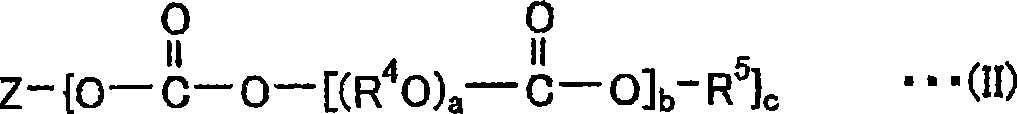

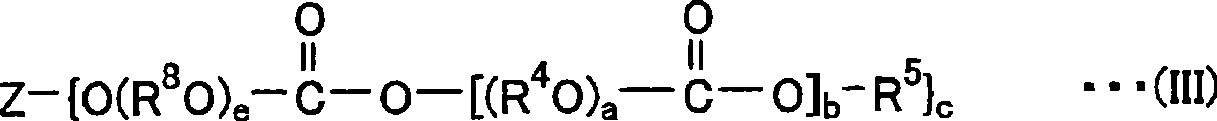

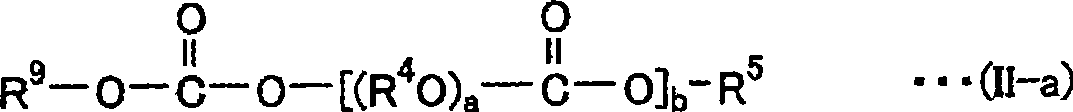

Disclosed is a refrigerator oil composition characterized by containing a synthetic base oil and a partial hydrocarbyl ether of an aliphatic polyhydric alcohol condensate. This refrigerator oil composition is also characterized in that the aliphatic polyhydric alcohol condensate is a hindered glycol and / or a 4-20 molecule condensate of an aliphatic polyhydric alcohol having 3-6 hydroxy groups. This refrigerator oil composition is preferably used for compression type refrigerating machines wherein a hydrofluorocarbon, a natural refrigerant such as a hydrocarbon, carbon dioxide or ammonia, a mixed refrigerant of fluorinated methyl iodide and propene, or an unsaturated fluorinated hydrocarbon, a fluorinated ether, a fluorinated alcohol, a fluorinated ketone or one of their mixtures is used as a refrigerant.

Description

technical field [0001] The present invention relates to a refrigerating machine oil composition, and in more detail relates to a low friction coefficient, excellent energy saving, suitable for various refrigerating fields (automotive air conditioners, gas heat pumps, air conditioners, refrigerators, vending machines, showcases, hot water supply systems, flooring Heating) for compression-type refrigerators and refrigerator oil compositions for refrigeration systems. Background technique [0002] In general, a compression refrigerator consists of at least a compressor, a condenser, an expansion mechanism (expansion valve, etc.), an evaporator, or a dryer, and its structure is a mixed liquid of refrigerant and lubricating oil (refrigerator oil) Circulate in this closed system. In this type of compression refrigerator, although the type of device is also affected, generally, the temperature in the compressor is high and the temperature in the cooler is low, so the refrigerant a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10M105/18C10M105/38C10M105/48C10M107/24C10M107/34C10M129/16C10N20/00C10N20/02C10N20/04C10N30/06C10N40/30

CPCC10M2223/041C10N2220/302C10N2220/021C10M2209/1023C10M2209/043C10M2207/042C10M171/008C10M2207/2835C10M2229/02C10N2230/10C10M2207/026C10N2230/02C10N2240/30C10M169/041C10N2230/06C10M2209/103C10M2209/1033C10M2207/046C10N2220/022C10N2020/04C10N2020/101C10N2020/02C10N2030/02C10N2030/10C10N2030/06C10N2040/30C10M105/18C10M107/24

Inventor 时合健生金子正人甲嶋宏明

Owner IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com