Intelligent automatic water filling system applicable to various water containers

A technology for automatic water filling and water containers, applied in applications, beverage preparation devices, household appliances, etc., can solve the problems of no drinking water outlets, inconvenient water cups, and inconvenient carrying, so as to promote the habit of using water bottles multiple times and improve Utilization, the effect of reducing the impact on human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

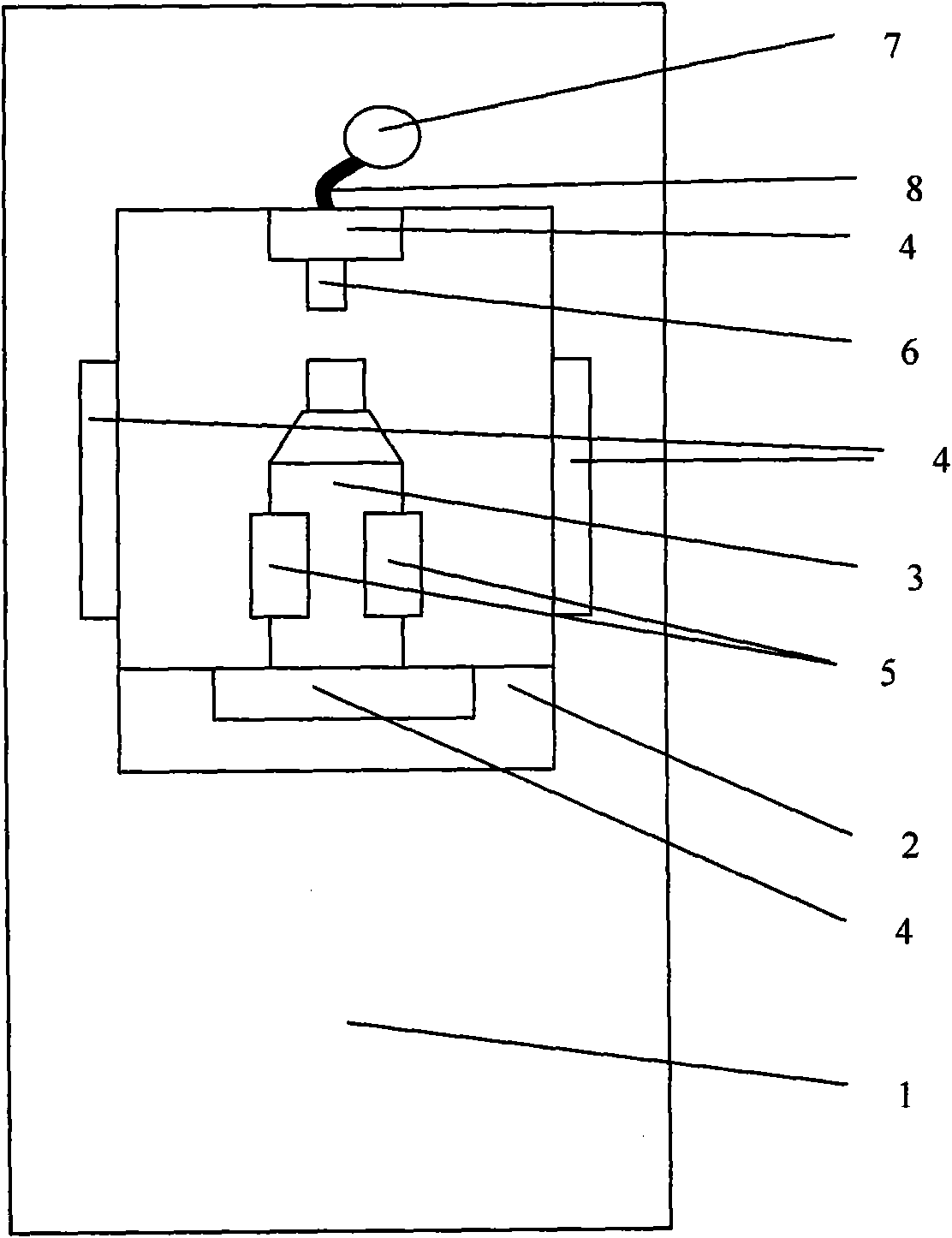

[0021] Implementation case 1: For specific implementation, please refer to figure 1 , there is a sunken platform 2 on the cabinet 1 for placing the water container 3, a movable water injection port 6 is installed above the platform 2, the diameter of the movable water injection port is 22 mm, and the platform 2 and the movable water injection port 6 There are fixing devices 5 manipulators between them, and sensor devices 4 ultrasonic detectors are installed on both sides of the fixing device 5, and a sensor device 4 is also installed on the movable water injection port 6, and the movable water injection port passes through the connecting conduit 8 Connect with metering pump 7 and connect with water source. When a water container 3 is put into the platform 2, the sensor device 4 transmits the detected signal to the control circuit, and the control circuit starts the fixing device 5 manipulator according to the signal of the sensor device 4 to fix the water container 3, and the ...

Embodiment example 2

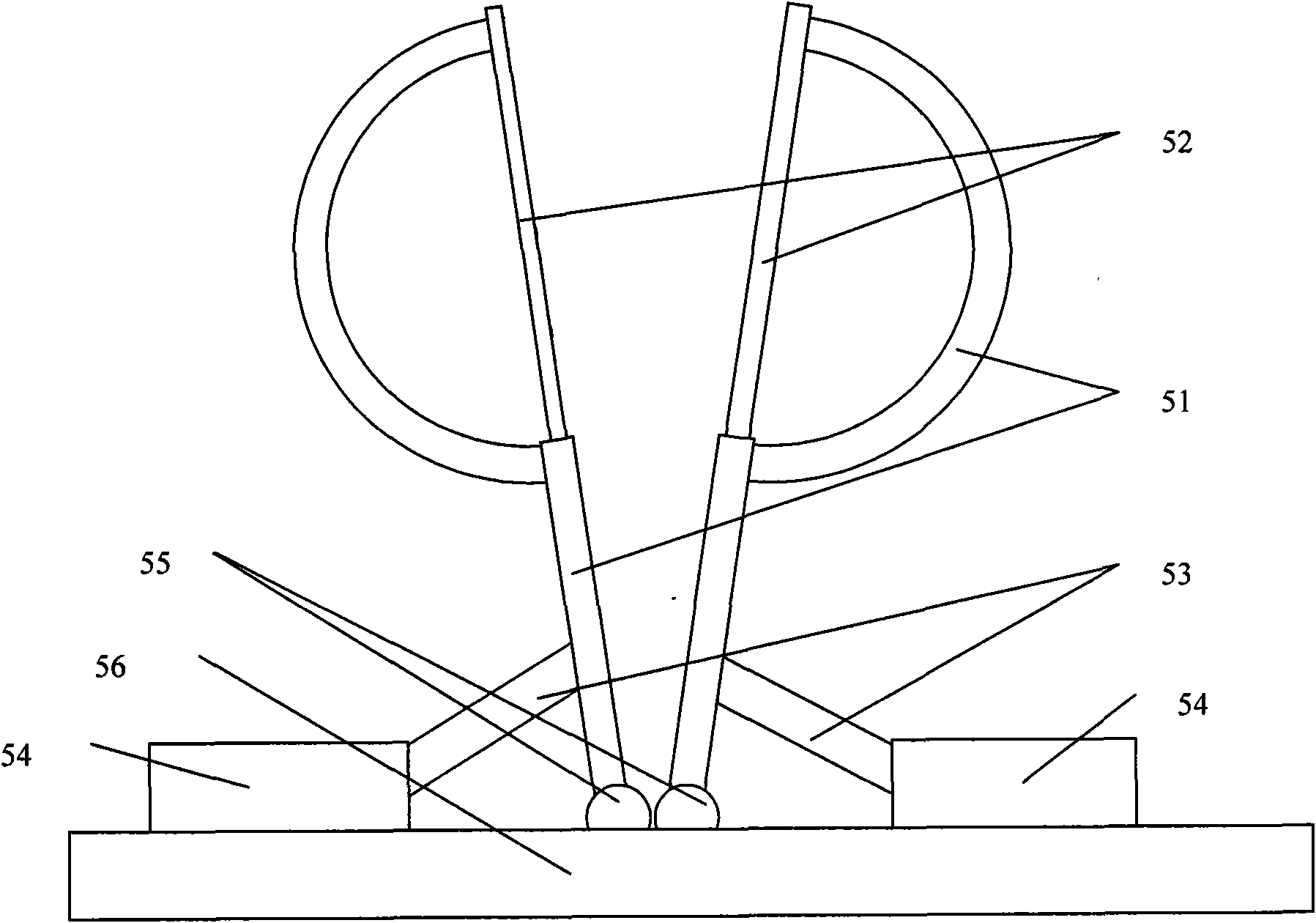

[0022] Implementation Case 2: As in Implementation Case 1, the fixing device can be fixed in other ways, such as using elastic straps, see figure 2 , the clamp arm 52 and the solenoid valve 54 of an automatic clamp similar to an enlarged test tube clamp are fixed on the fixed plate 56, and an elastic belt 52 is placed at the position of the clamp arm 51 semicircle, when a water container is put into the clamp that is opened After receiving the command from the control circuit, the solenoid valve 54 drives the connecting rod 53 to move, so that the clamp arms 52 move closer to each other with the hinge 55 as the center, so that the clamp arms 52 contact the water container and undergo elastic deformation, so as to achieve the purpose of fixing the water container and The effect of not destroying the outer wall of the water container.

Embodiment example 3

[0023] Implementation case 3: As in implementation case 1, the sensor uses a microwave detector to judge the physical and chemical characteristics of the water container through microwave detection of objects placed on the platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com