Preparation method for increasing content of total saponin, low polarity saponin and argininyl fructosy glucose in red ginseng

A technology of arginine disoside and total saponin, which is applied to the processing of small polar saponins and arginine disoside content, increases the field of total saponins in red ginseng, and can solve the problem that ginsenosides are easily lost, lost, and the yield of AFG decreases. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Processing method

[0021] Select 6-8 fresh ginseng, clean them, seal some of them, put them in the steamer box, and steam them at 100°C for 3 hours. When the steaming time is over, let the ginseng cool in the steamer box to 60°C naturally. Then take them out and put them into an oven to dry at 50° C. for 5 days to obtain red ginseng with increased content of total saponins, small polar saponins and arginine diglucoside.

[0022] A part of the above-mentioned washed fresh ginseng was directly put into the above-mentioned drawer as a control group, steamed and dried according to the same conditions, and the red ginseng processed by the traditional method was obtained.

[0023] (2) Sample solution preparation

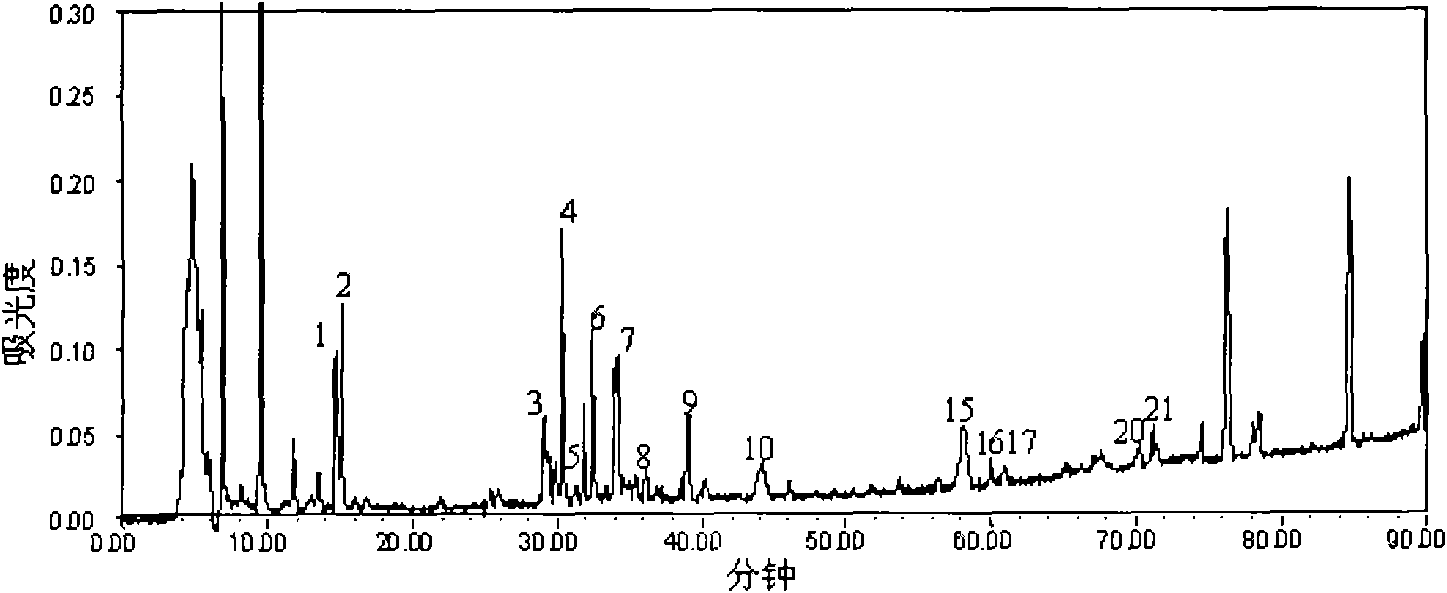

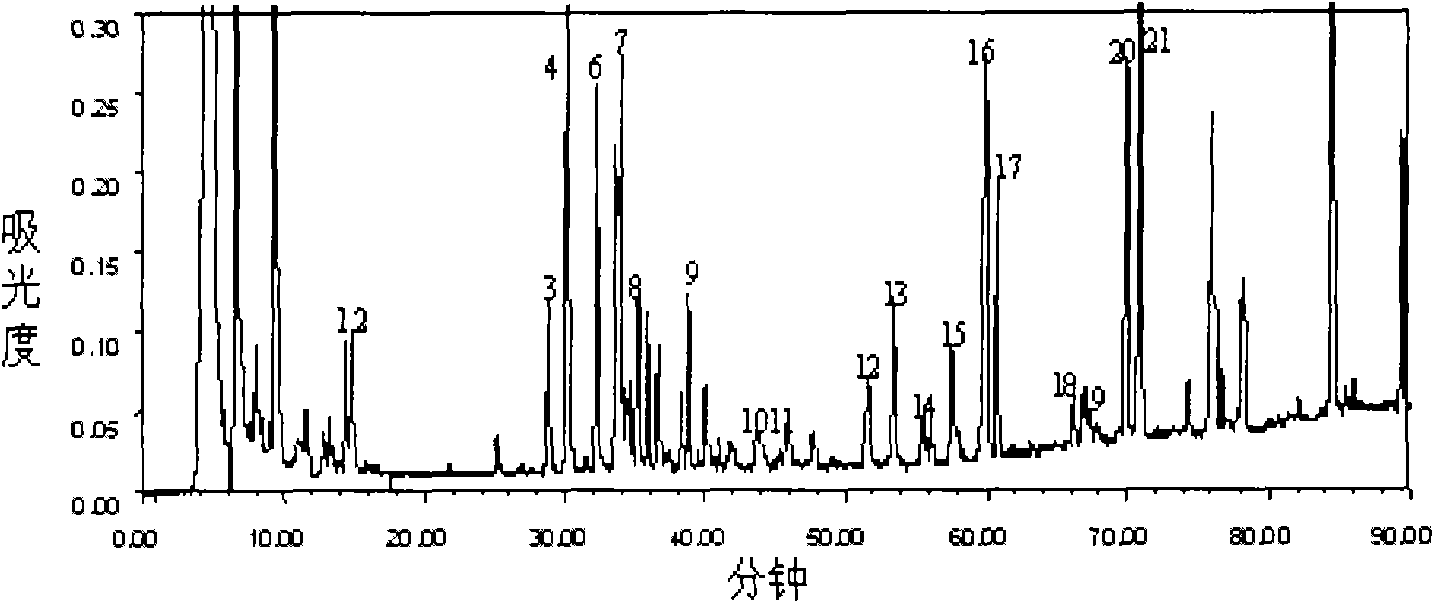

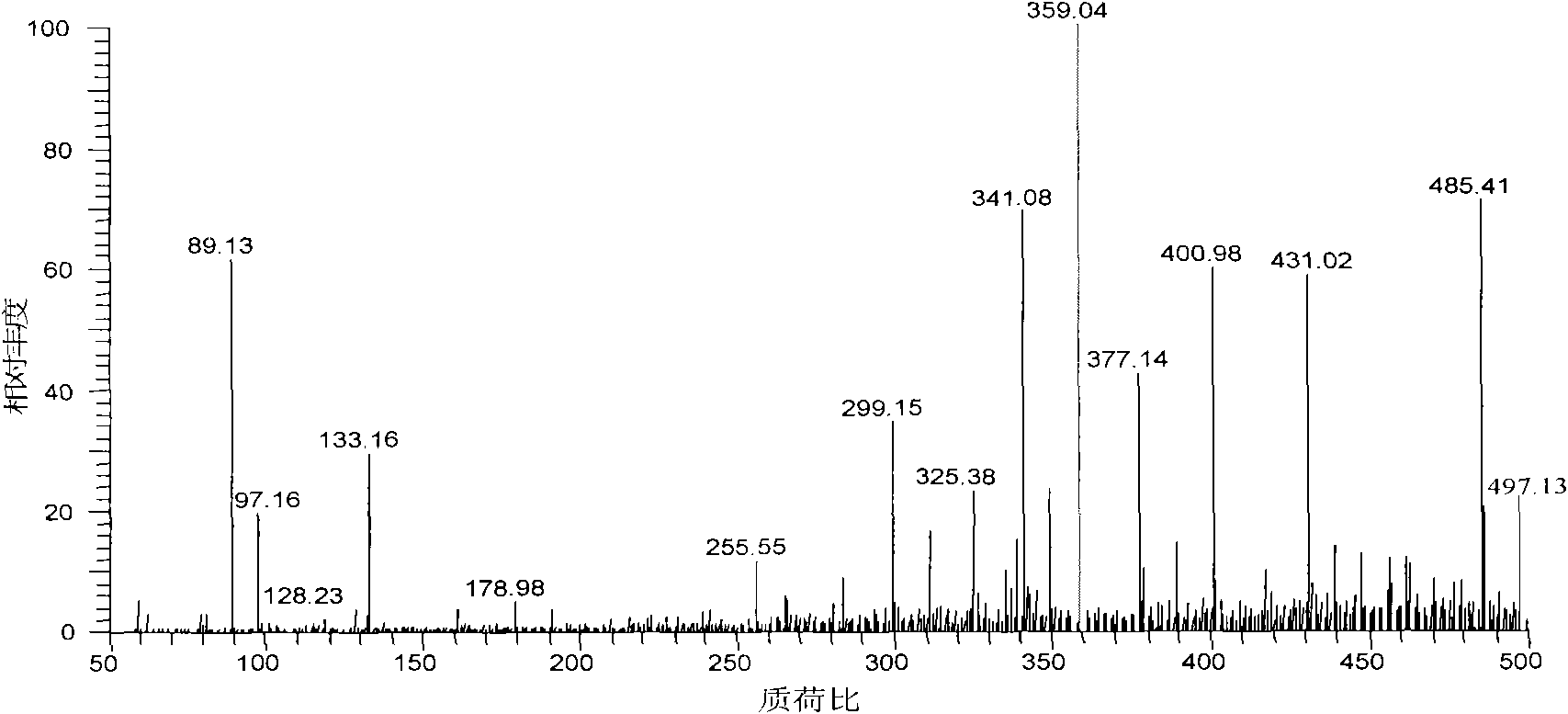

[0024] Take 1g powder of the red ginseng obtained by the method provided by the present invention and the red ginseng reference standard obtained by the traditional method, add 20ml of methanol, ultrasonically extract at 40°C for 1h, filter, evaporate the meth...

Embodiment 2

[0029] Select 6-8 fresh ginseng, clean them, seal some of them, put them in the steamer box, and steam them at 110°C for 1.5 hours. When the steaming time is over, let the ginseng cool naturally in the steamer box to 60°C, and then take them out. Finally, put them into an oven and dry them at 50°C for 5 days to obtain red ginseng with increased contents of total saponins, small polar saponins and arginine diglucoside.

[0030] A part of the above-mentioned washed fresh ginseng was directly put into the above-mentioned drawer as a control group, steamed and dried according to the same conditions, and the red ginseng processed by the traditional method was obtained.

[0031] Sample solution preparation and sample detection are the same as in Example 1.

[0032] As a result, the content of total saponins of red ginseng obtained by the method provided by the invention increased by 21.73%, the content of small polar saponins increased by 25.41%, and the content of AFG increased by ...

Embodiment 3

[0034] Select 6-8 fresh ginseng, clean them, seal some of them and put them in the steamer of the ginseng box, and steam them at 110°C for 3 hours. When the steaming time is over, let the ginseng cool naturally in the steamer box to 60°C, and then take it out Then put them into an oven and dry them at 50° C. for about 5 days to obtain red ginseng with increased content of total saponins, small polar saponins and arginine diglucoside.

[0035] A part of the above-mentioned washed fresh ginseng was directly put into the above-mentioned drawer as a control group, steamed and dried according to the same conditions, and the red ginseng processed by the traditional method was obtained.

[0036] Sample solution preparation and sample detection are the same as in Example 1.

[0037] As a result, the content of total saponins of red ginseng obtained by the method provided by the invention increased by 51.22%, the content of small polar saponins increased by 83.48%, and the content of AFG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com