Oil-water separation method and device

An oil-water separation device and technology for oil-water separation, applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve problems that have not been widely used, and achieve the effects of reducing volume, improving separation efficiency, and accurate oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

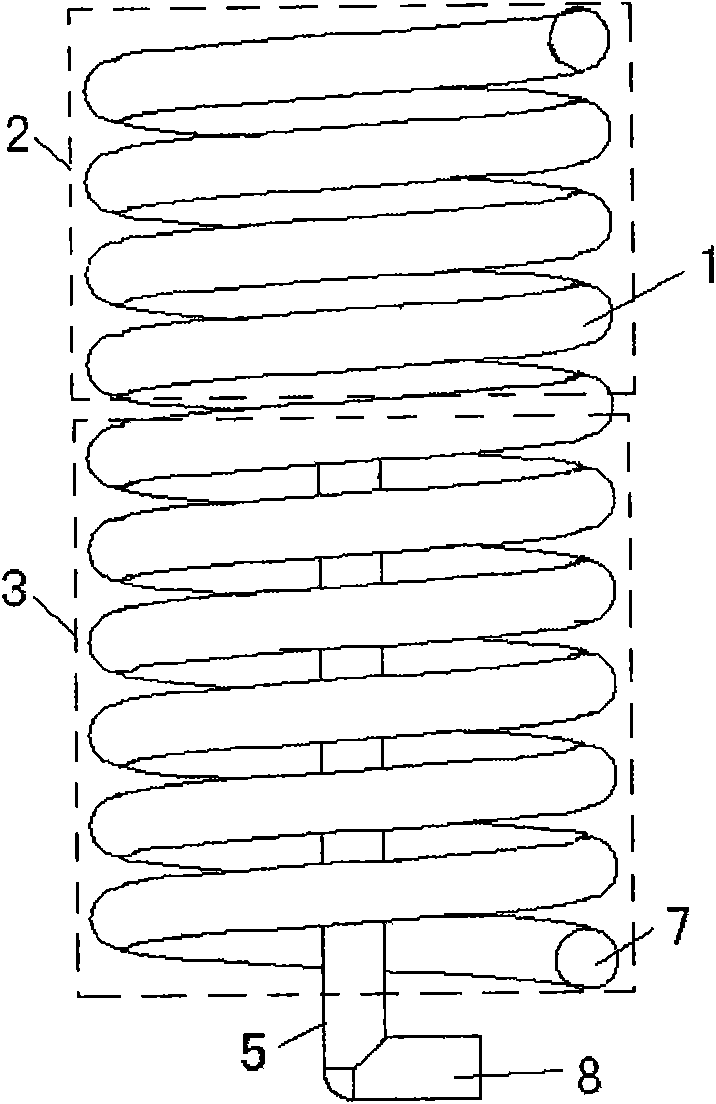

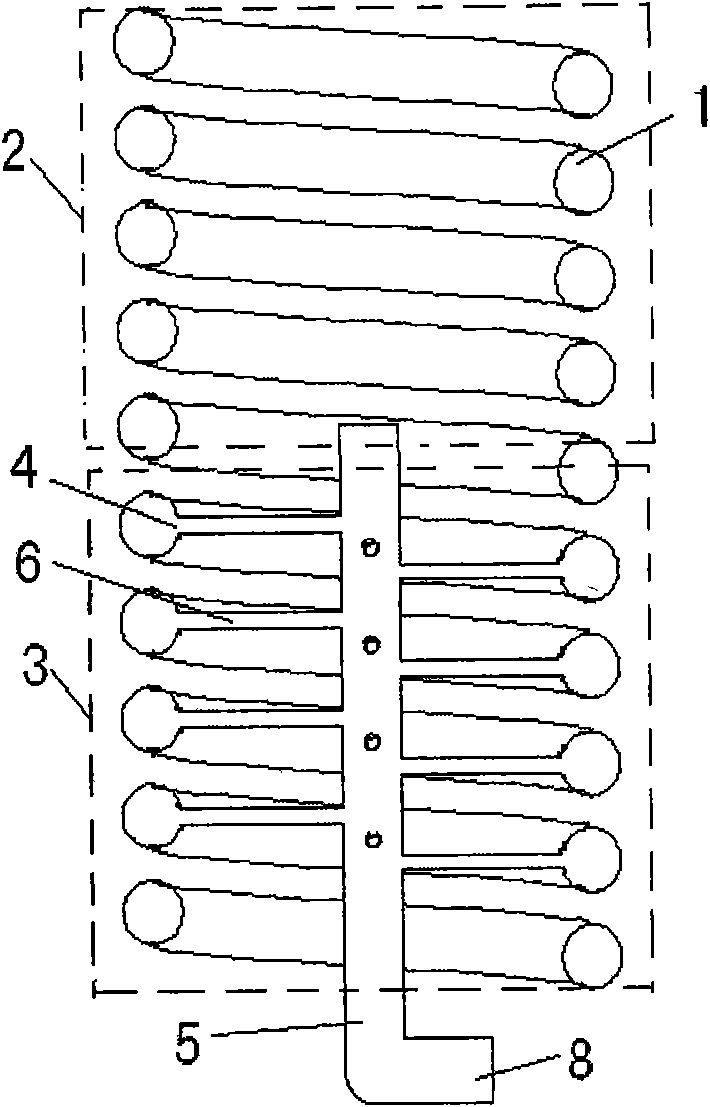

[0017] Such as figure 1 , figure 2 As shown, a helical pipe 1 is provided, and the helical pipe 1 is divided into an upper pipe 2 and a lower pipe 3 connected as a whole, and a plurality of holes 4 are arranged at intervals on the inner side of the pipe wall of the lower pipe 2, and an oil collecting pipe is arranged in the center of the lower pipe 2 5. Connect the pipe wall of the oil collecting pipe 5 to the corresponding hole 4 on the inner wall of the lower pipe 2 through several connecting pipes 6 .

[0018] The present invention makes use of the density difference between oil and water and the centrifugal force generated by the rotating flow of the oil-water mixture in the spiral tube 1, so that the oil-water mixture gradually separates from the top to bottom oil-water interface in the upper tube 2, and a stable oil-water mixture is formed aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com