Bottle pipe conveying mechanism for full automatic heating blowing machine

A technology of conveying mechanism and stretch-blow machine, which is applied in the field of plastic machinery, can solve problems such as inaccurate positioning of stretch-blow mechanism, elongated transmission chain, complex equipment structure, etc., and achieve the effects of saving heating power, simplifying structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

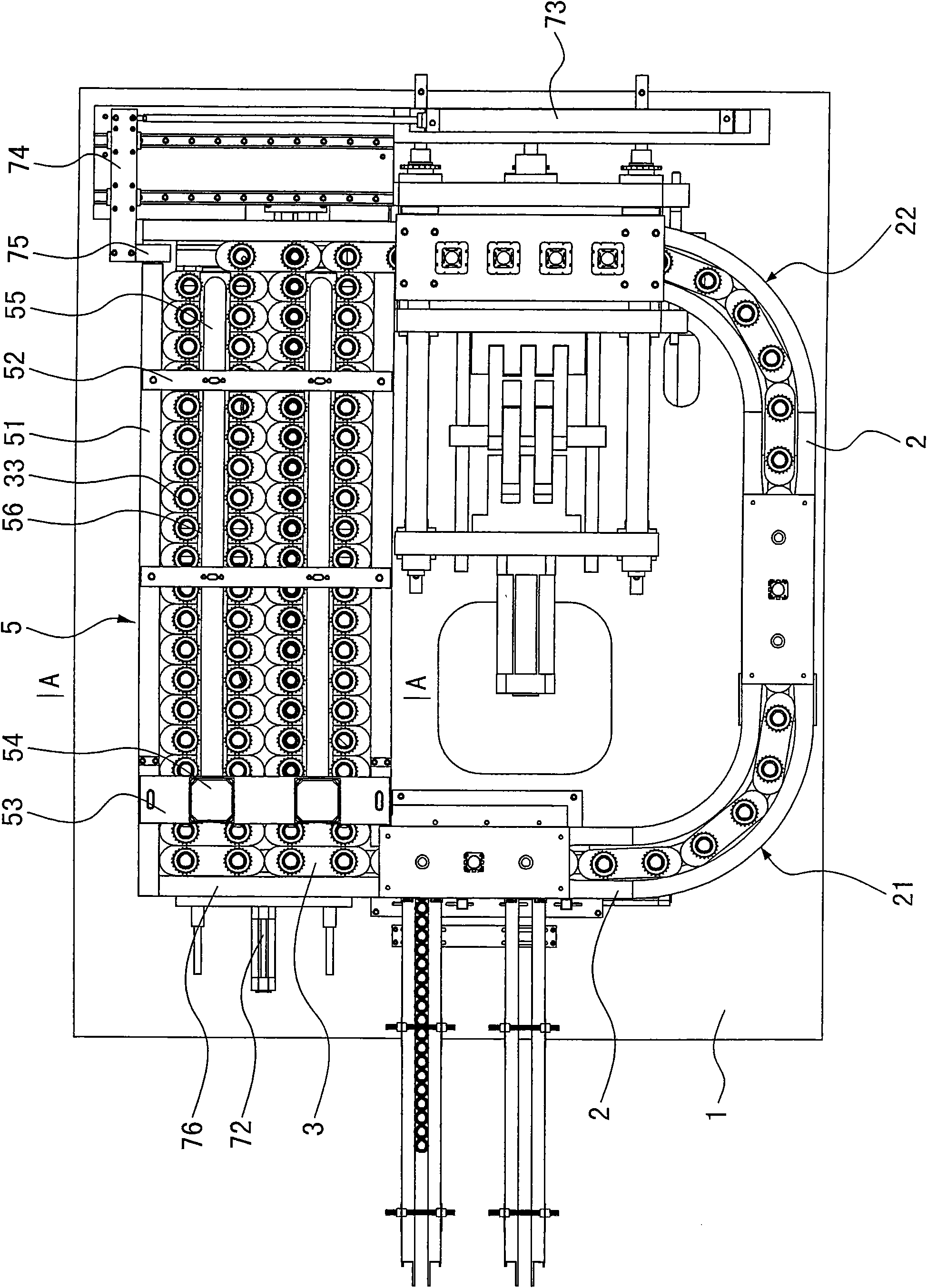

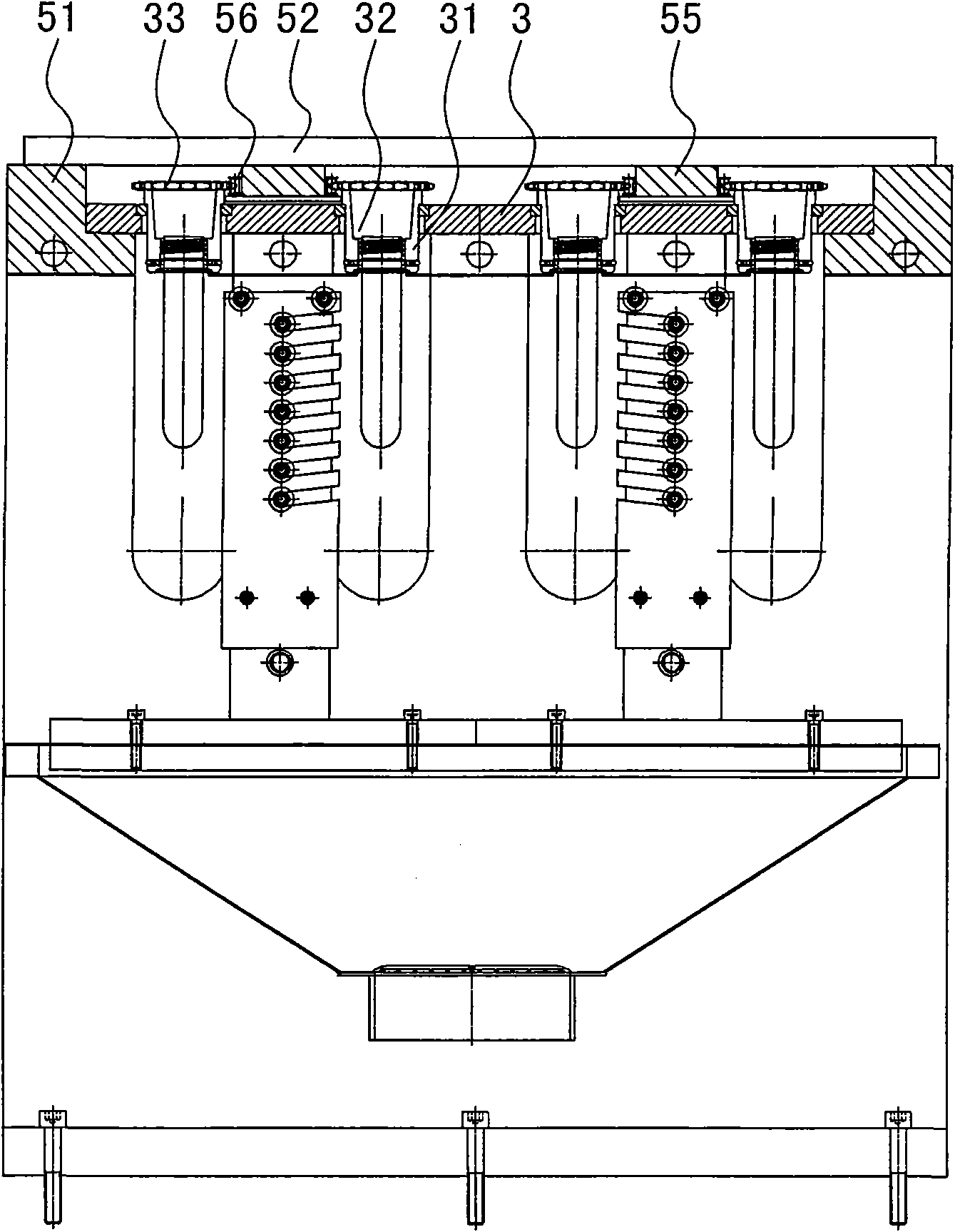

[0009] The invention relates to a bottle tube conveying mechanism of a fully automatic heating stretch blowing machine, such as figure 1 , figure 2 As shown, it includes frame 1, on which the bottle tube conveying track is installed, and the bottle tube support is installed in the track. The bottle tube support is driven by power. The track is divided into feeding area, heating area, stretch blow molding area and bottle ejection The area is characterized in that the track is a slide rail 2, and the support includes a slider 3, a rotating shaft 31 is installed in the sliding block, and a bottle insertion tube shaft hole 32 is formed in the rotating shaft, and there is a self- Runner 33, bottle tube supporting member is promoted by cylinder in slide rail 2, and slide block 3 enters heating zone 5 and changes into horizontal arrangement and advances, and the rotating shaft 31 after horizontal arrangement is 2 rows or 4 rows or more than 4 rows. In this scheme, the support for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com