Preparation method of induced texture ferroelectric film at buffer layer

A ferroelectric thin film and buffer layer technology, applied in the field of ferroelectric thin film preparation, can solve the problems of poor performance of ferroelectric thin films, achieve good dielectric and piezoelectric properties, reduce formation and accumulation, and achieve good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

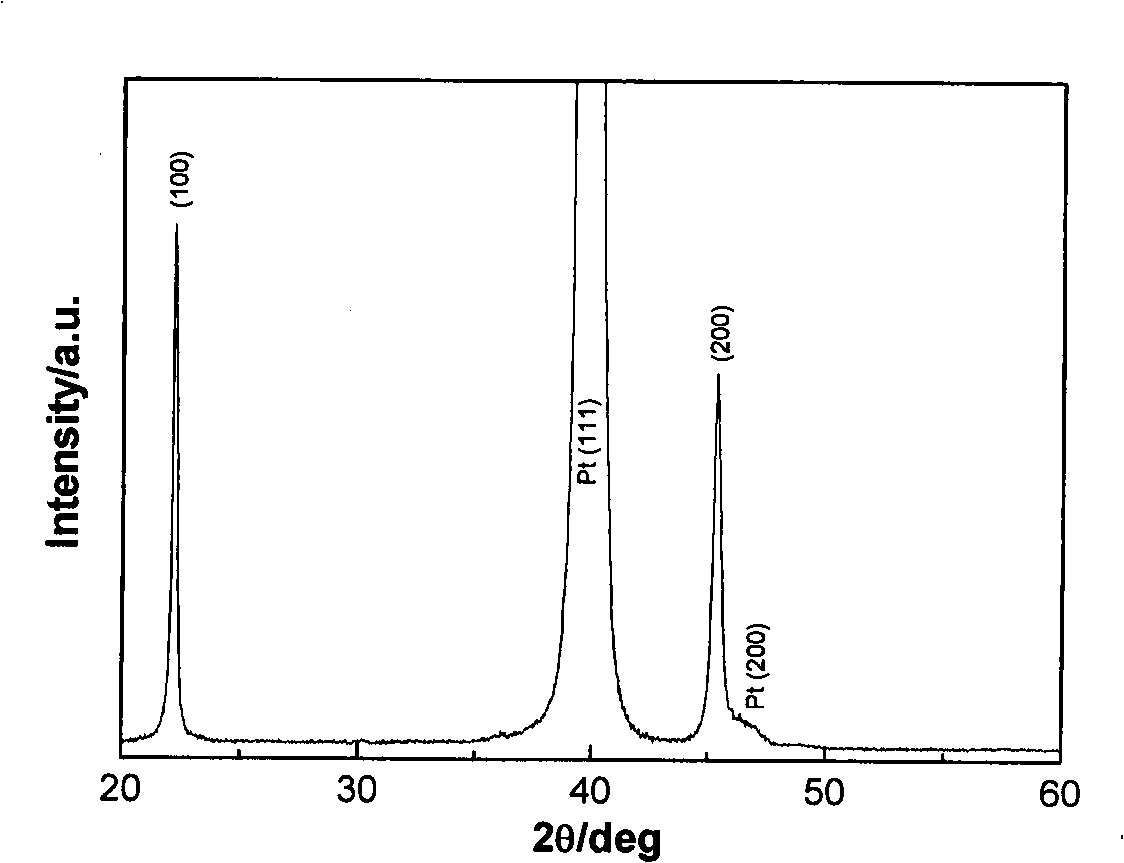

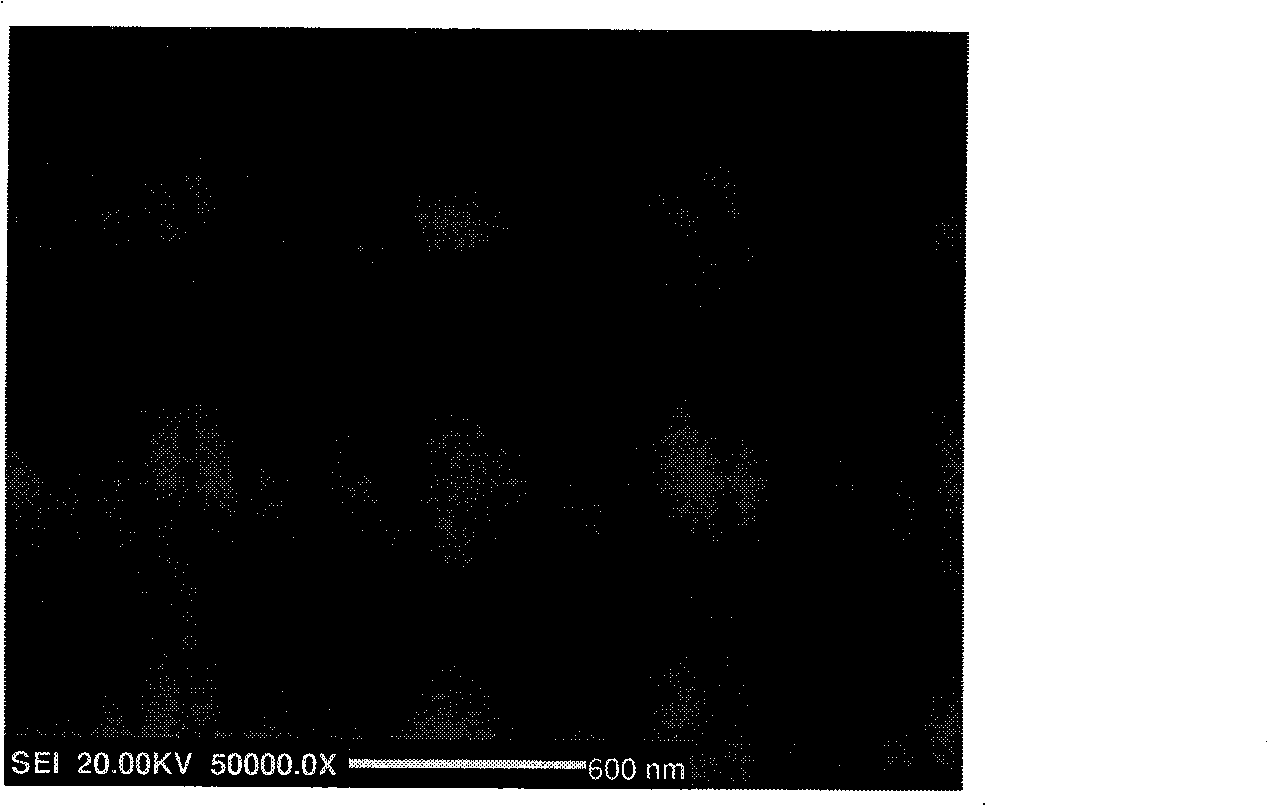

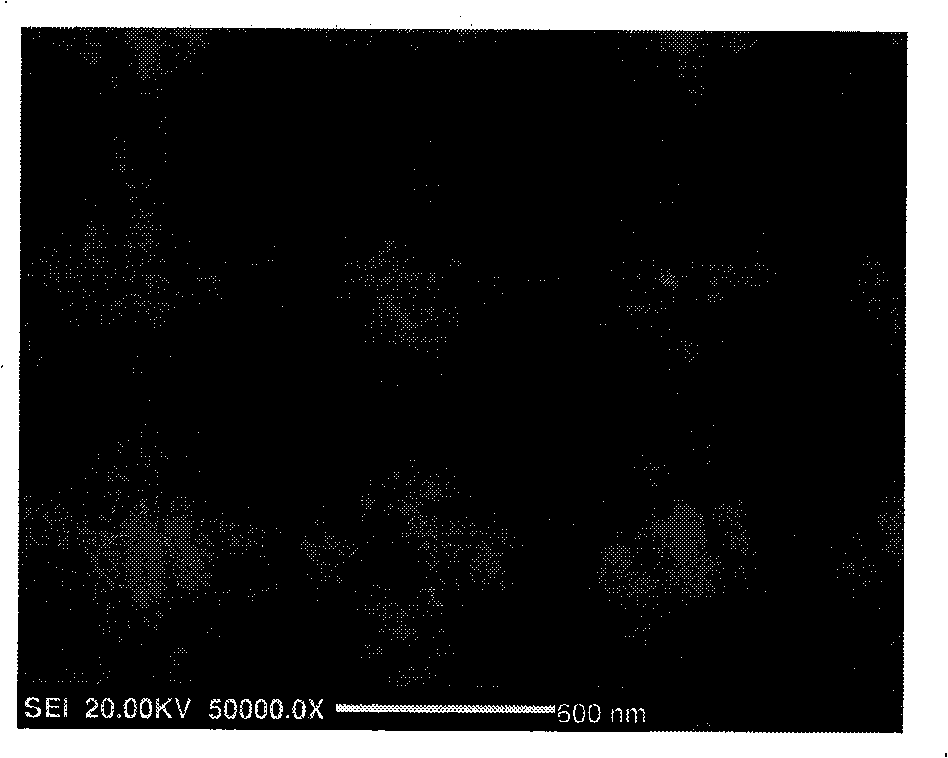

[0009] Specific embodiment one: the preparation method of the buffer layer induced texture ferroelectric thin film of the present embodiment is carried out according to the following steps: 1. According to the ratio of parts by weight, 1.6 to 2 parts of lanthanum nitrate, 1 to 1.2 parts of nickel acetate and 10 to 10 parts of 30 parts of ethylene glycol methyl ether were mixed, then stirred and heated until completely dissolved; namely, to obtain LaNiO 3 Buffer layer sol; 2. Add the buffer layer sol dropwise on the substrate, spin coating at 1000-2000r / min for 5-15s, then spin-coat at 3500-4500r / min for 15-25s, and keep warm at 300-450°C for 4- 5min, then annealed at 600-800°C for 5-15min, and cooled to room temperature to form a buffer layer film; 3. Add ferroelectric oxide sol onto the buffer layer film, and spin coat at 1000-2000r / min for 5- 15s, spin coating at 3500-4500r / min for 15-25s, keep warm at 300-450°C for 4-5 minutes, then anneal at 600-800°C for 5-15 minutes, coo...

specific Embodiment approach 2

[0011] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 1.7 to 1.9 parts of lanthanum nitrate, 1.05 to 1.15 parts of nickel acetate and 15 to 25 parts of ethylene glycol methyl Ether mixed, then stirred and heated until completely dissolved; that is, LaNiO 3 Sol. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment two is that in step one, 1.8 parts of lanthanum nitrate, 1.2 parts of nickel acetate and 20 parts of ethylene glycol methyl ether are mixed according to the ratio of parts by weight, and then stirred and heated until completely dissolved; that is, to obtain LaNiO 3 Sol. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com