Method for constructing highly plastic clay core wall

A high-plasticity clay and construction method technology, applied in the direction of wall dams, dams, barrages, etc., can solve the problems of destroying the permeable capillaries of high-plasticity clay, unable to meet the plasticity of construction performance, high-plasticity of high-plasticity clay, etc., to achieve good operating conditions , Guarantee the quality of rolling and improve the anti-seepage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

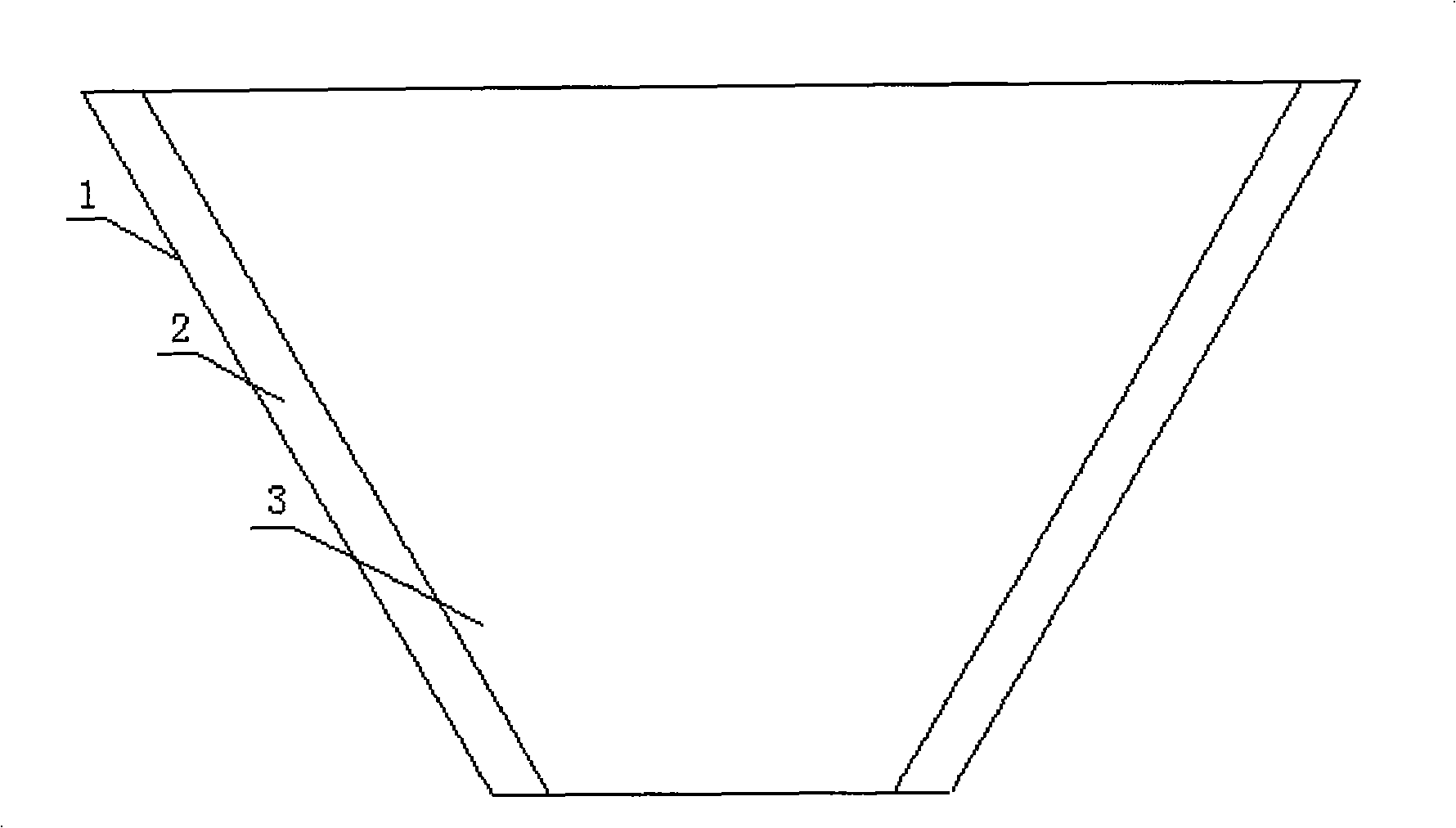

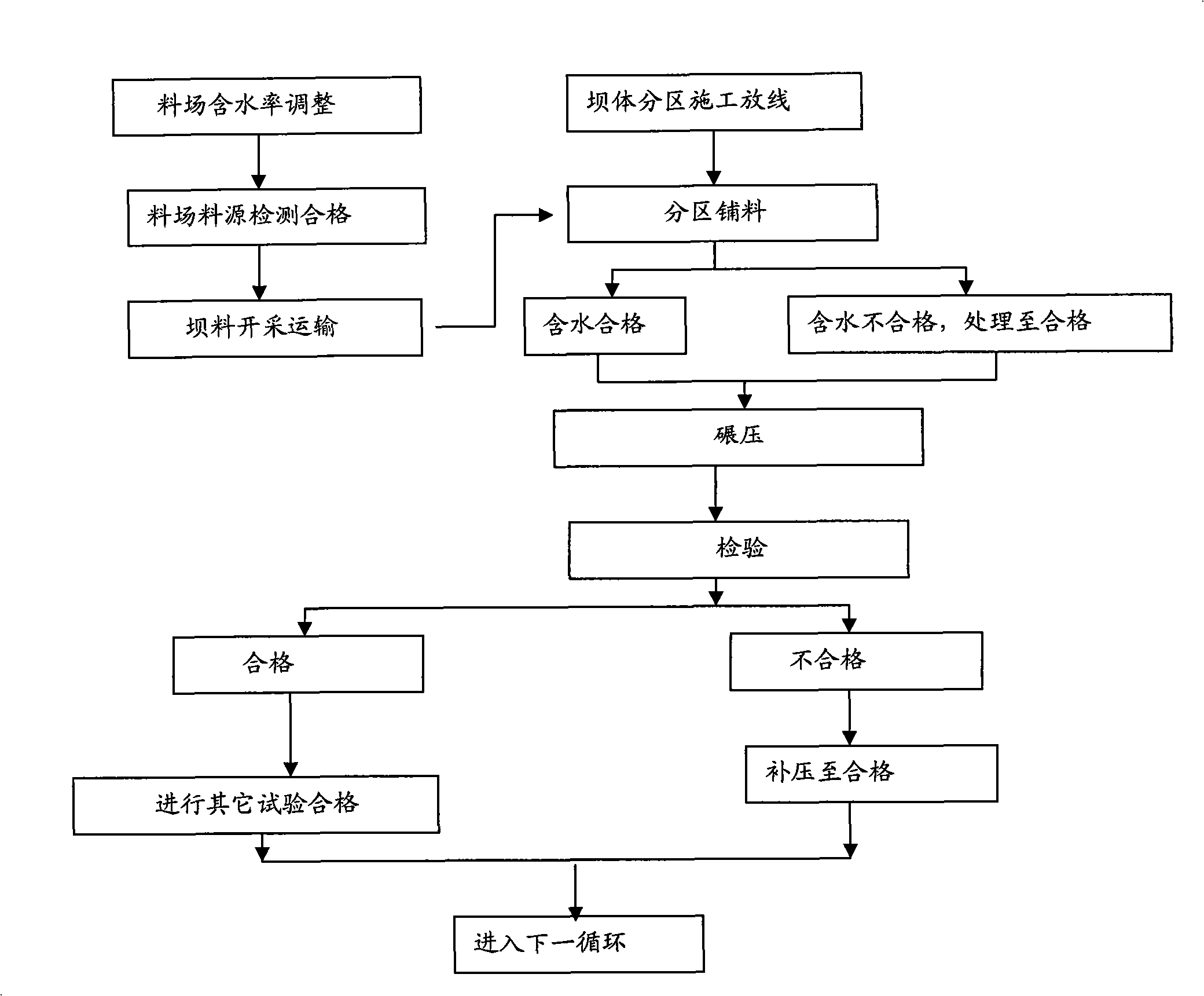

[0016] see figure 1 and figure 2 , construction method of the present invention comprises the following steps:

[0017] 1) Adjust the moisture content of high plastic clay in the stockyard.

[0018] Adopt high moisture content direct dam filling technology, directly excavate and transport from the stockyard to the storage site downstream of the dam, pile up into "earth cows" and cover them with colored strips of cloth, and directly dig into the dam for filling when in use; according to According to the test results, when the surface of the soil layer on the dam surface is dry and needs to be supplemented with water, the sprinkler is used to sprinkle water directly on the dam surface. It is required to mix the pressure water and compressed air to spray in the form of mist to make the water evenly distributed. After watering, use a disc harrow Blend well.

[0019] 2) The high plastic clay in the stockyard is qualified: compaction degree ≥ 99%, permeability coefficient -5 cm / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com