Pile extraction construction method

A construction method and technology on the construction site, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as exceeding the compressive strength of concrete, requiring high pile head strength, and unable to pull out multi-section piles, etc., to avoid skewing , good pore forming effect, and strong promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

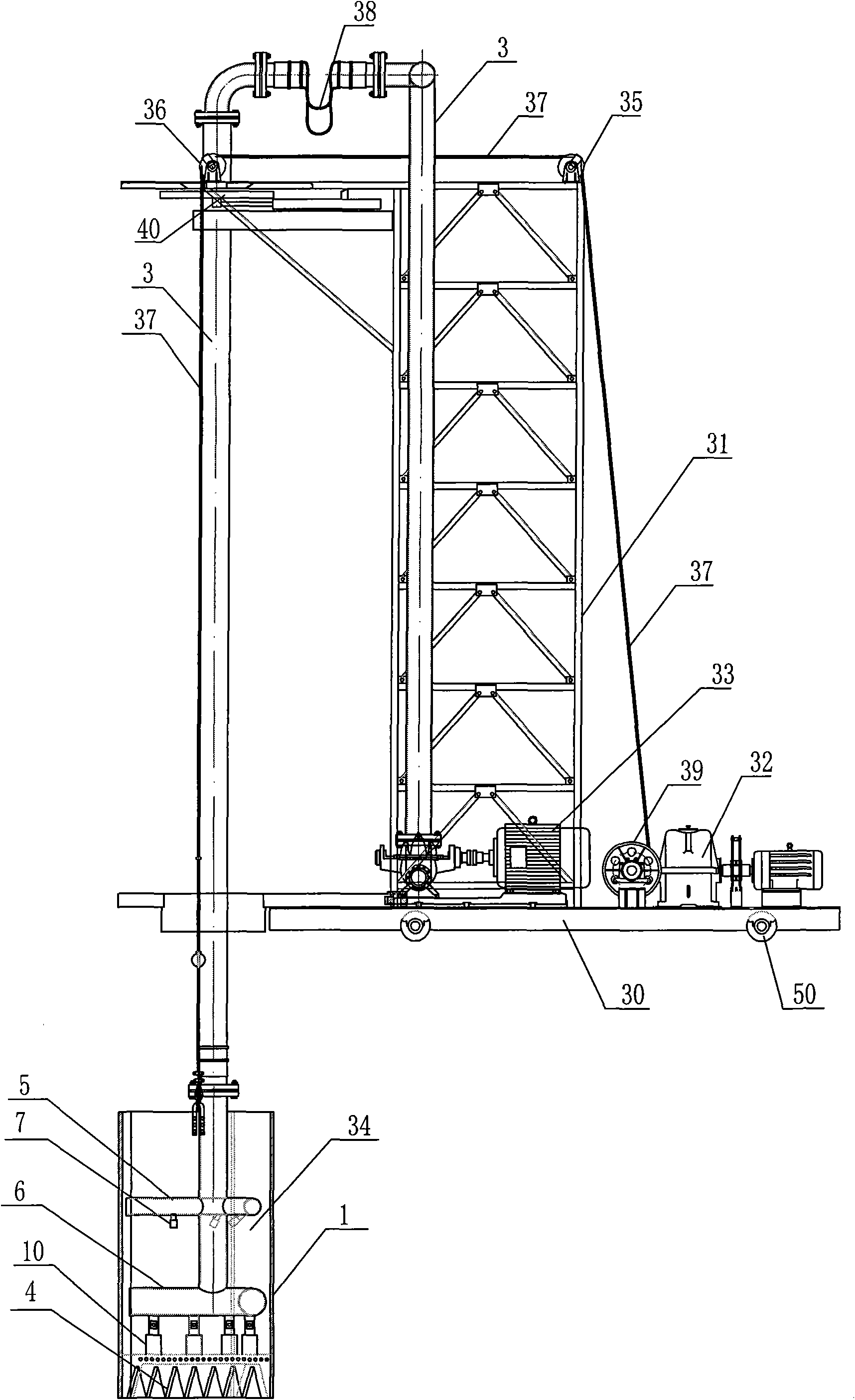

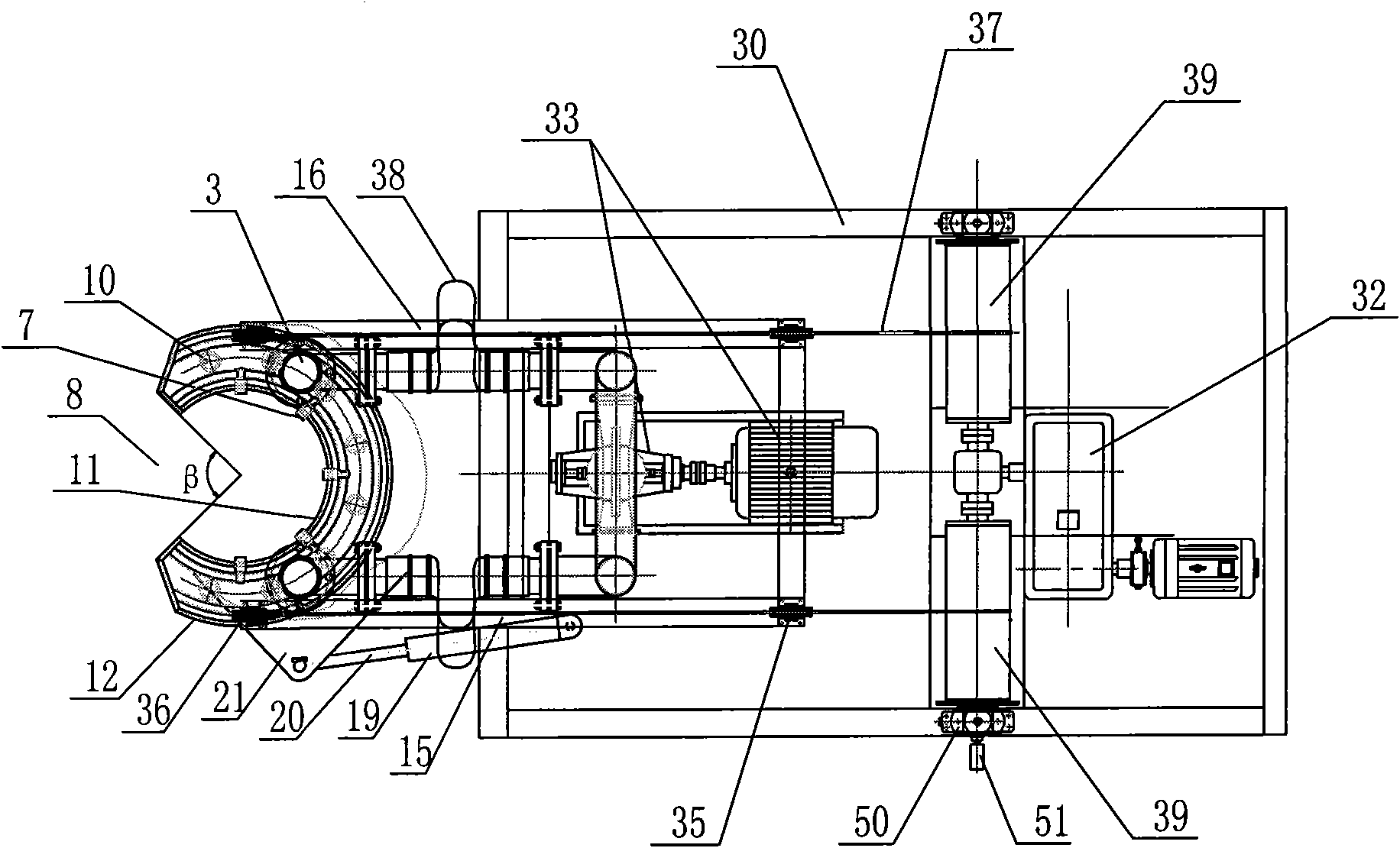

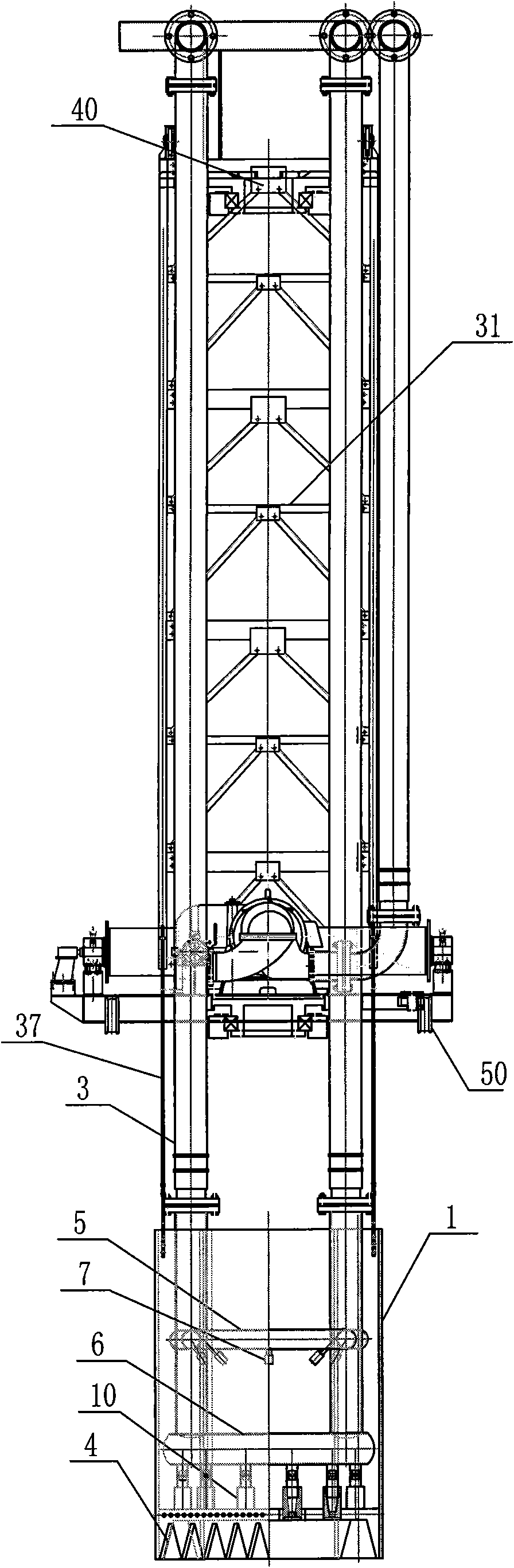

[0019] Such as figure 1 , figure 2 and image 3 Shown, each equipment / component among the present invention comprises chassis frame 30, vertical frame 31, winch 32, water pump-motor 33 (water supply system) and hole former 34, and vertical frame 31, winch 32 and water pump-motor 33 are arranged On the chassis frame 30, the vertical frame 31 is welded or bolted by channel steel and diagonal braces. The top of the vertical frame 31 is provided with a pulley 35 and a pulley 36. The hoist 32 and the hole forming device 34 are wound on the pulley 35 and the pulley 36. The rope 37 transmission connection, the rope 37 is a steel wire rope, the size and model are determined according to the actual situation, the water outlet of the water pump-motor 33 is connected with the hole forming device 34 through the water inlet pipe 3, and the water inlet pipe 3 above the stand 31 is provided with a section of flexible pipe 38. The hole forming device 34 comprises a hole forming device bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com