Intelligent device for testing tensile force of electric capstan in real time

A real-time detection and intelligent technology, applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of insufficient accuracy and low efficiency, so as to improve production efficiency and accuracy, high precision, and operation Convenient and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

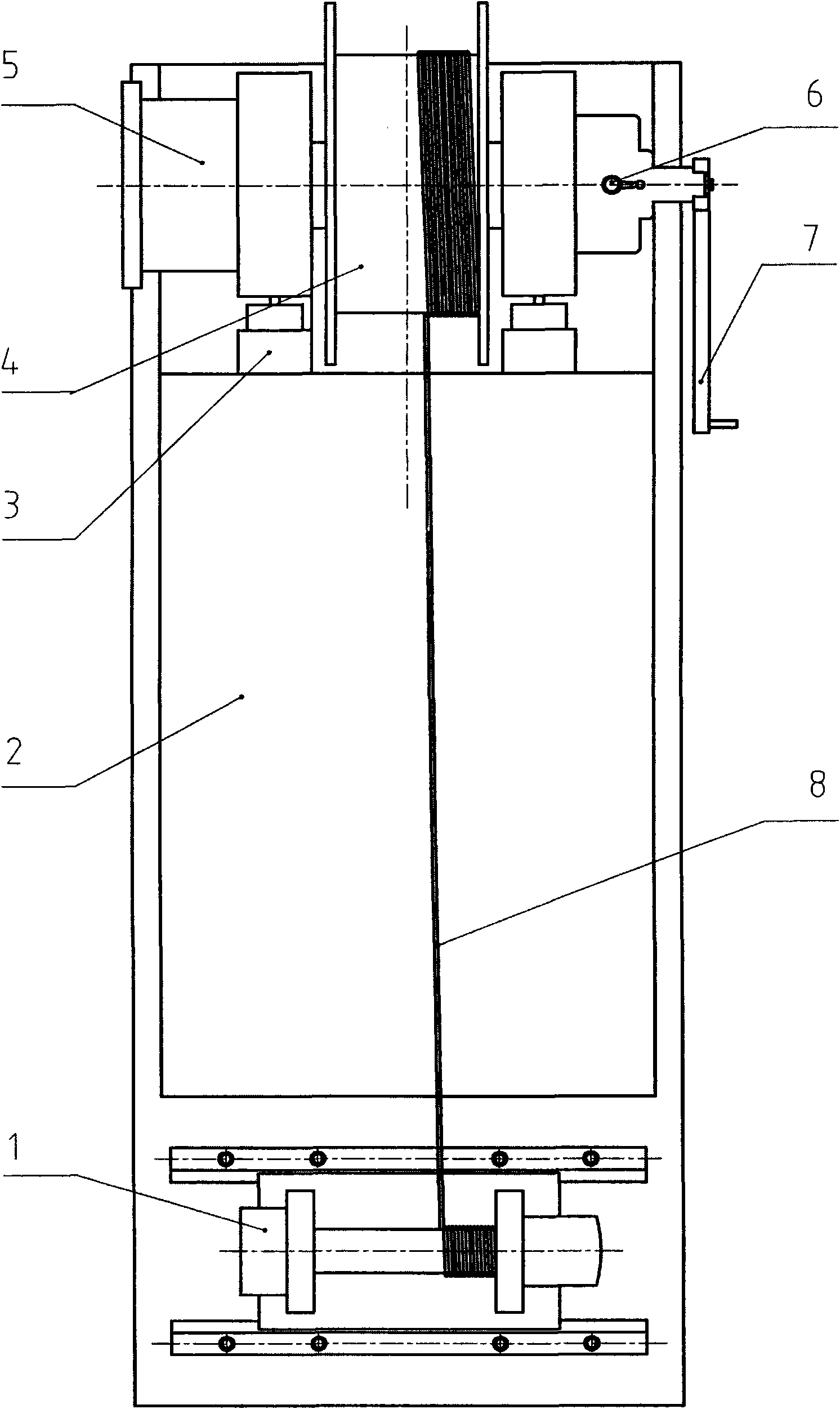

[0010] During the test, the electric winch (1) is supplied with normal operating current and voltage, and the electric winch (1) works to pull the wire rope (8) to drive the drum assembly (4) to rotate. Since the roller assembly (4) and the magnetic powder brake (5) jointly generate load, and act on the torque sensor (3) installed at both ends of the roller assembly (4), the load roller (4) is measured by the torque sensor (3). torque. The signal obtained by the torque sensor (3) is collected by a PLC (programmable logic controller), and the sampled data is synchronously transmitted to a computer for calculation, archiving, and later data processing. The start and stop of the electric winch (1) under test is automatically controlled by the computer; the change of the tension of the electric winch (1) can be observed in real time through the computer, and a real-time tension characteristic curve and inspection report can be drawn as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com