Explosion-proof module structure for power components, particularly power semiconductor components, and production thereof

A power module and power device technology, which is applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as high conduction voltage, overheating of power semiconductor devices, and damage of power semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

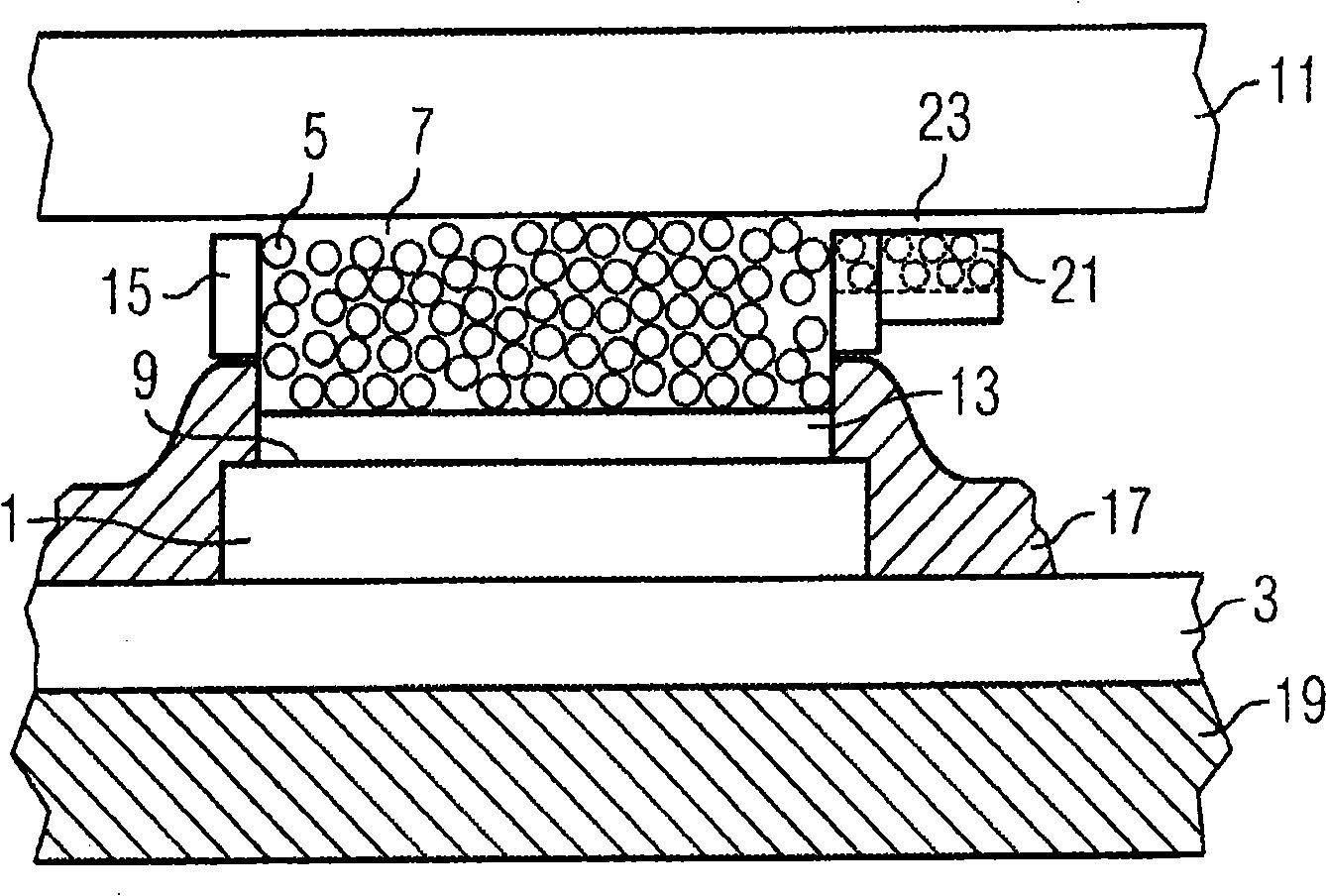

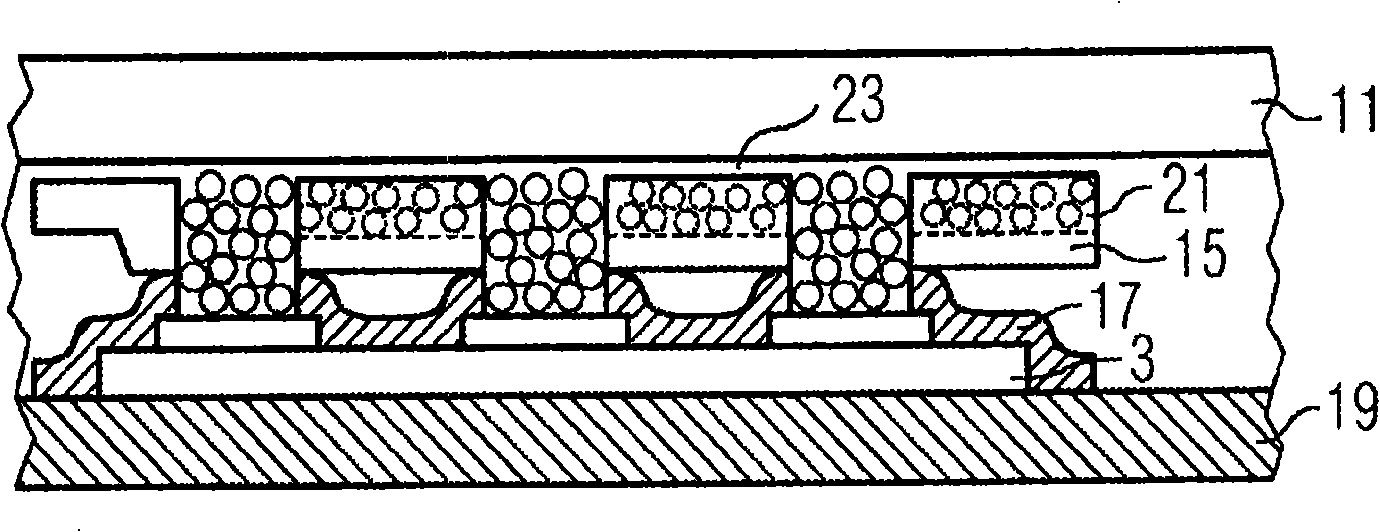

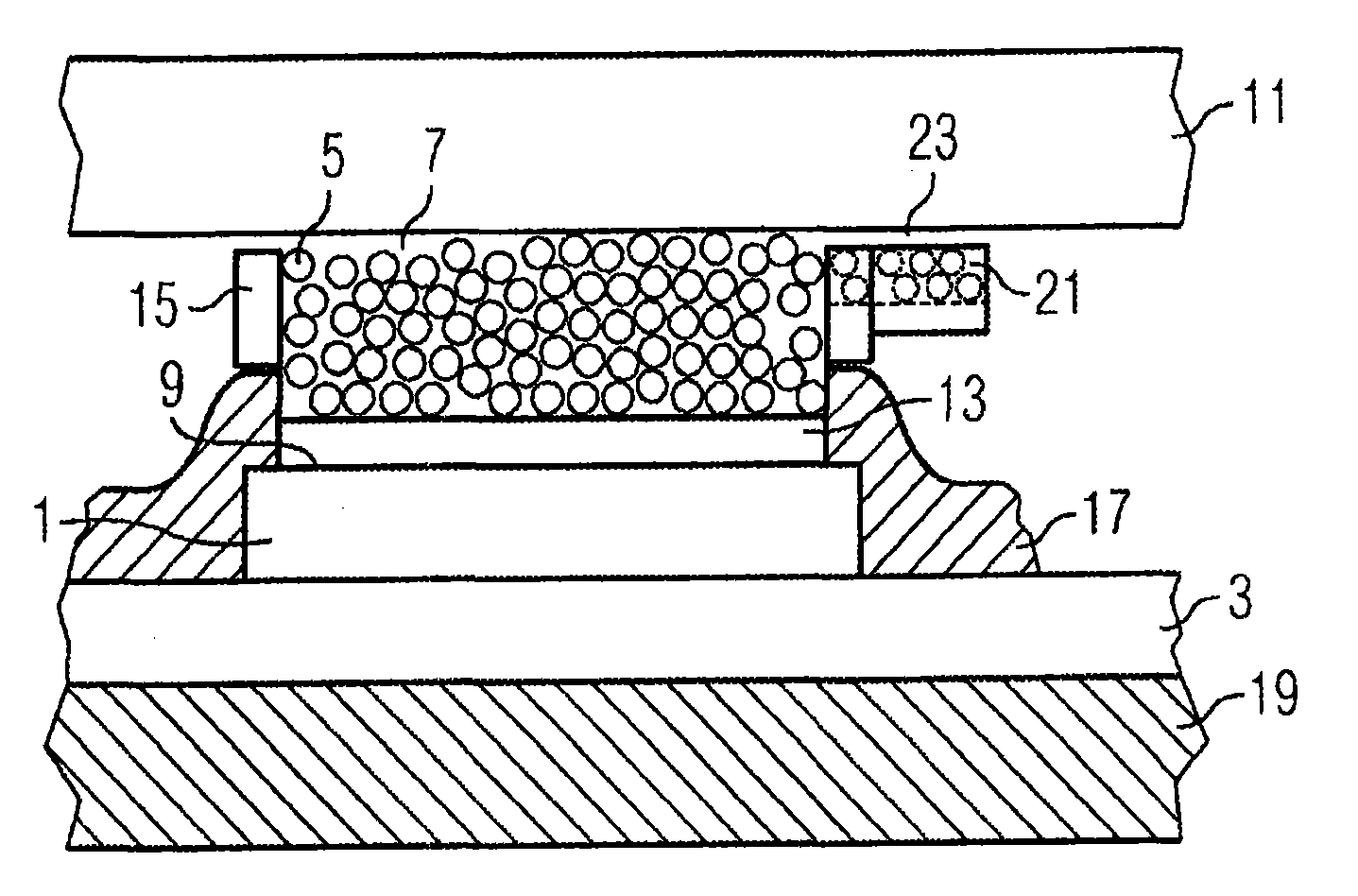

[0029] figure 1 The first embodiment of the power module according to the present invention is shown. According to the explosion-proof module structure, the explosion pressure is leaked by the filling consisting of conductive particles 5 (for example, metal balls with a diameter of 0.5 mm to 2 mm) and a channel 23 for pressure reduction, where the channel 23 for pressure reduction is along Box 15 is generated. According to this embodiment, a power device is realized, in particular, an electronic power semiconductor device 1 is realized. The electronic power semiconductor device 1 has a first load current generated on the bottom side of the power semiconductor device 1. Electrical contact. Furthermore, by means of the electrical contact surface 9, a second electrical contact for the load current is produced on the upper side of the power semiconductor component 1. The power semiconductor device 1 is arranged on a substrate 19. The first electrical contact on the side facing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com