Fuel cell, method for manufacturing fuel cell, and unit cell assembly

A single battery and fuel cell technology, applied to fuel cell parts, fuel cells, solid electrolyte fuel cells, etc., can solve problems that cannot be said to be easy, and achieve the effects of suppressing deformation, improving maintainability, and being easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, a fuel cell, a fuel cell manufacturing method, and a cell module according to the present invention will be described based on examples with reference to the drawings.

[0043] A. Example:

[0044] Composition of fuel cells

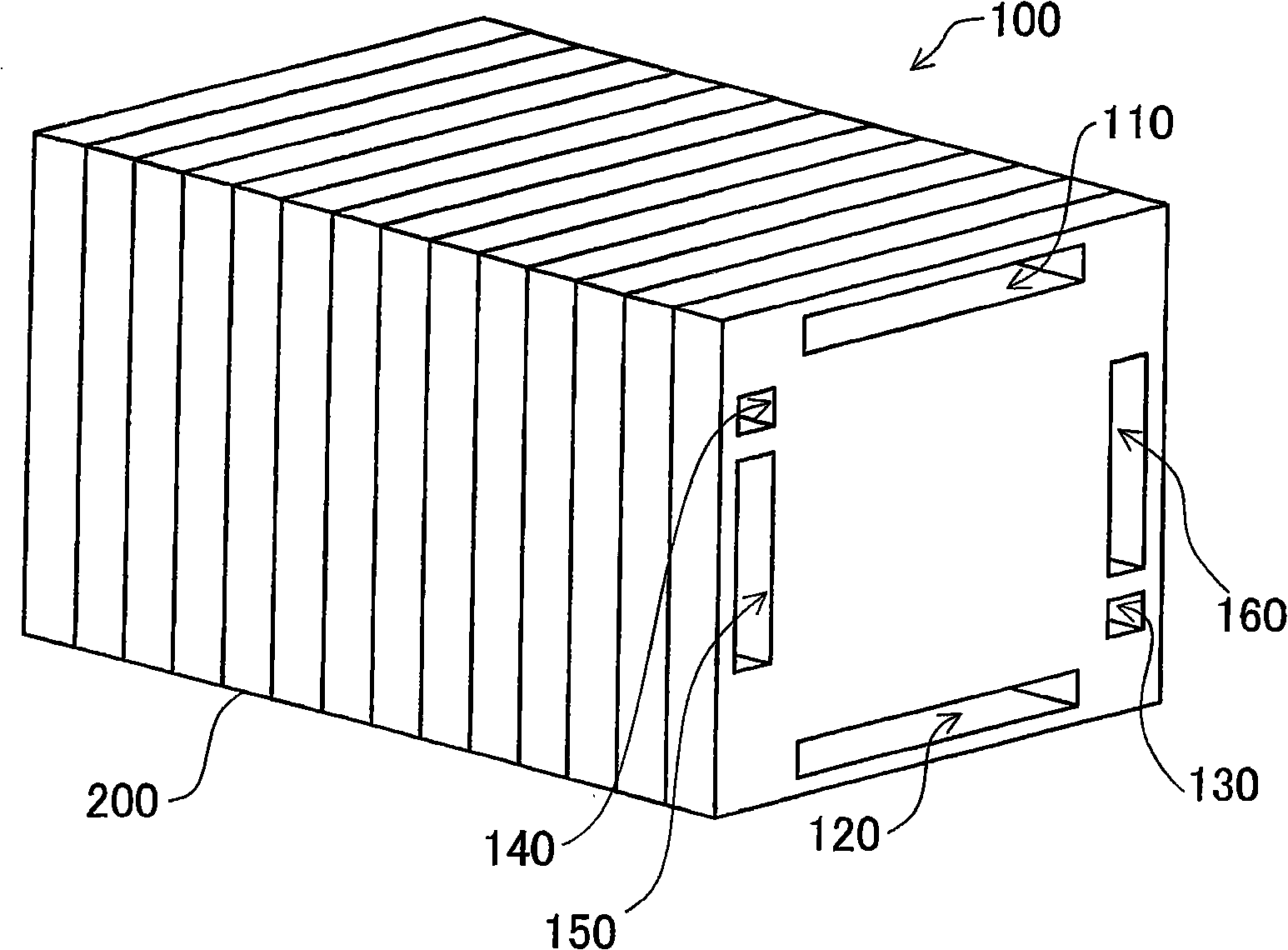

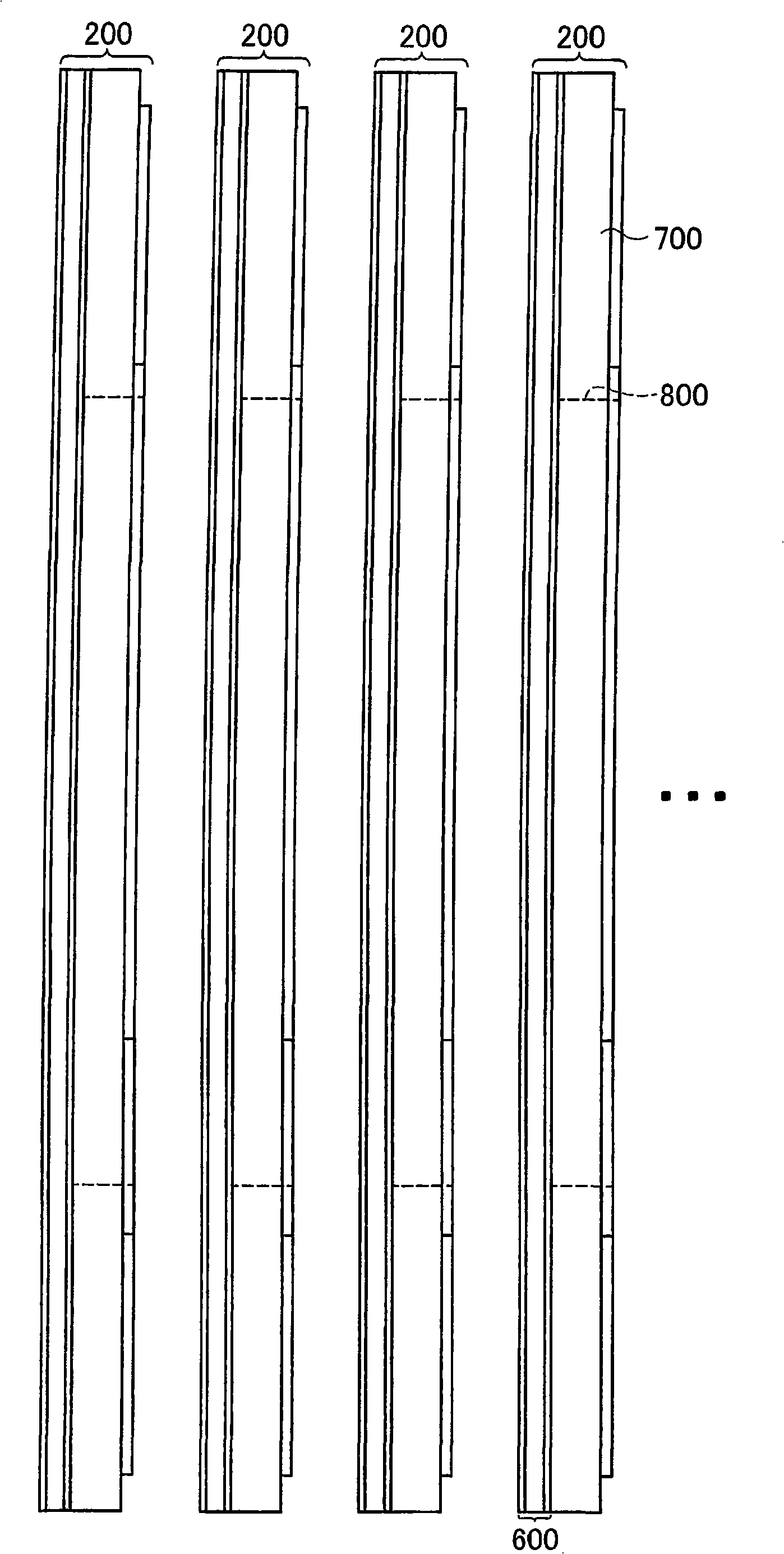

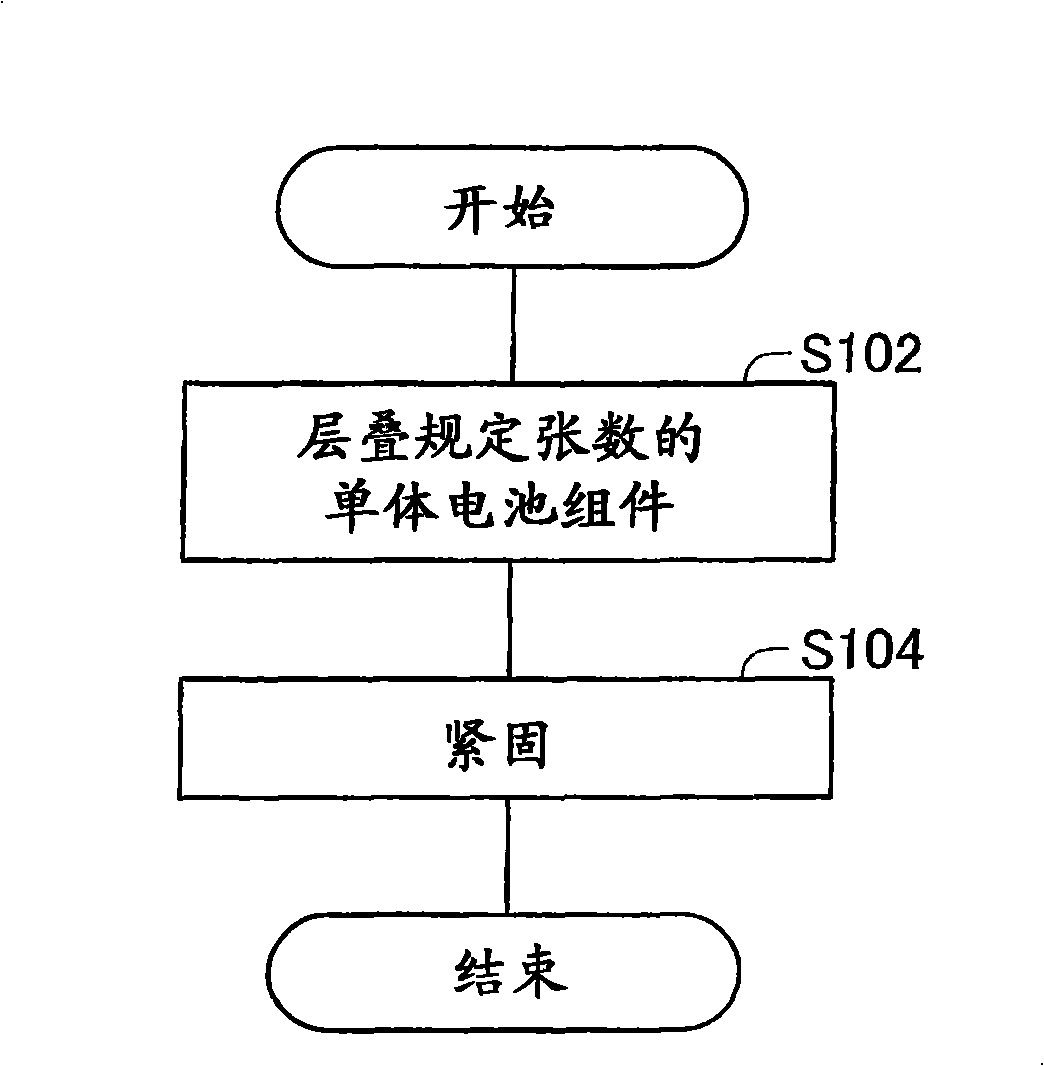

[0045] A schematic configuration of a fuel cell according to an embodiment of the present invention will be described. figure 1 and figure 2 It is an explanatory diagram showing the configuration of the fuel cell in the example. image 3 It is a flowchart showing the manufacturing steps of the fuel cell in the example.

[0046] Such as figure 1 and figure 2 As shown, the fuel cell 100 has a structure in which a plurality of unit cell assemblies 200 are stacked (so-called stack structure). Such as image 3 As shown, the fuel cell 100 is manufactured through the following steps: stacking a predetermined number of unit cell assemblies 200 (step S102), and applying a predetermined fastening force in the stacking direction to tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com