Method for producing renewable aggregate by using construction waste

A technology of construction waste and recycled aggregates, which is applied in the field of construction waste treatment in cities, can solve the problems of increasing the workload of crushers, easy dust flying, environmental pollution, etc., to reduce dust flying, reduce workload, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

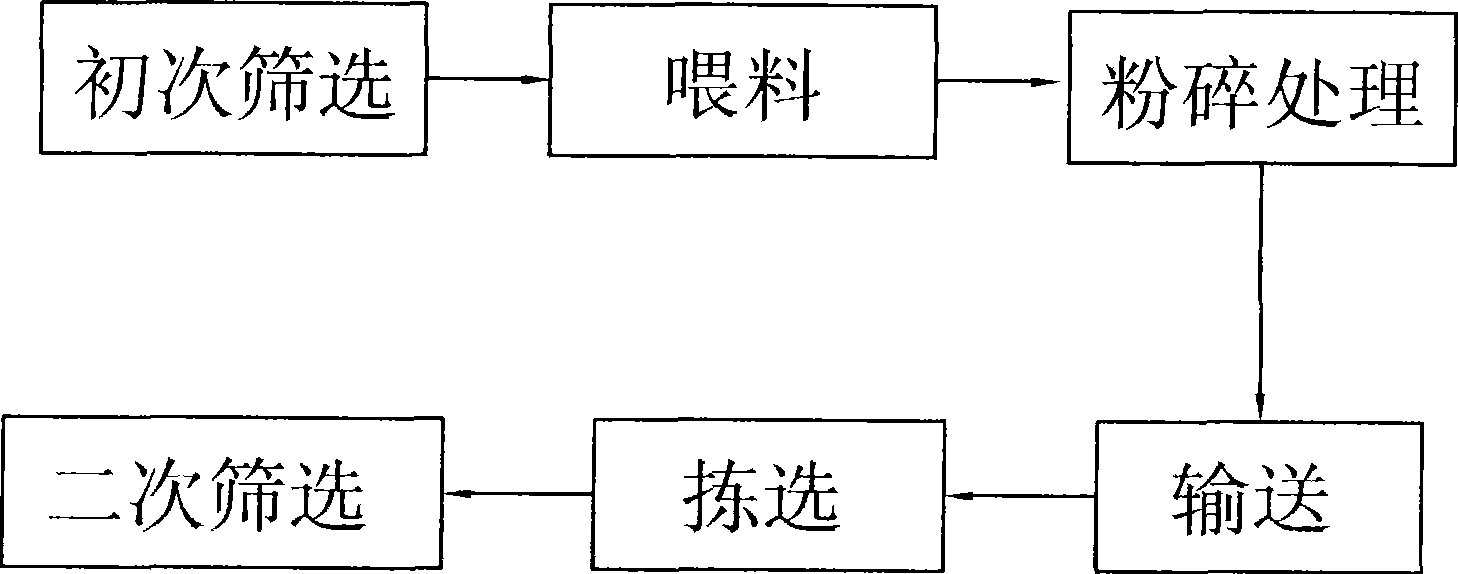

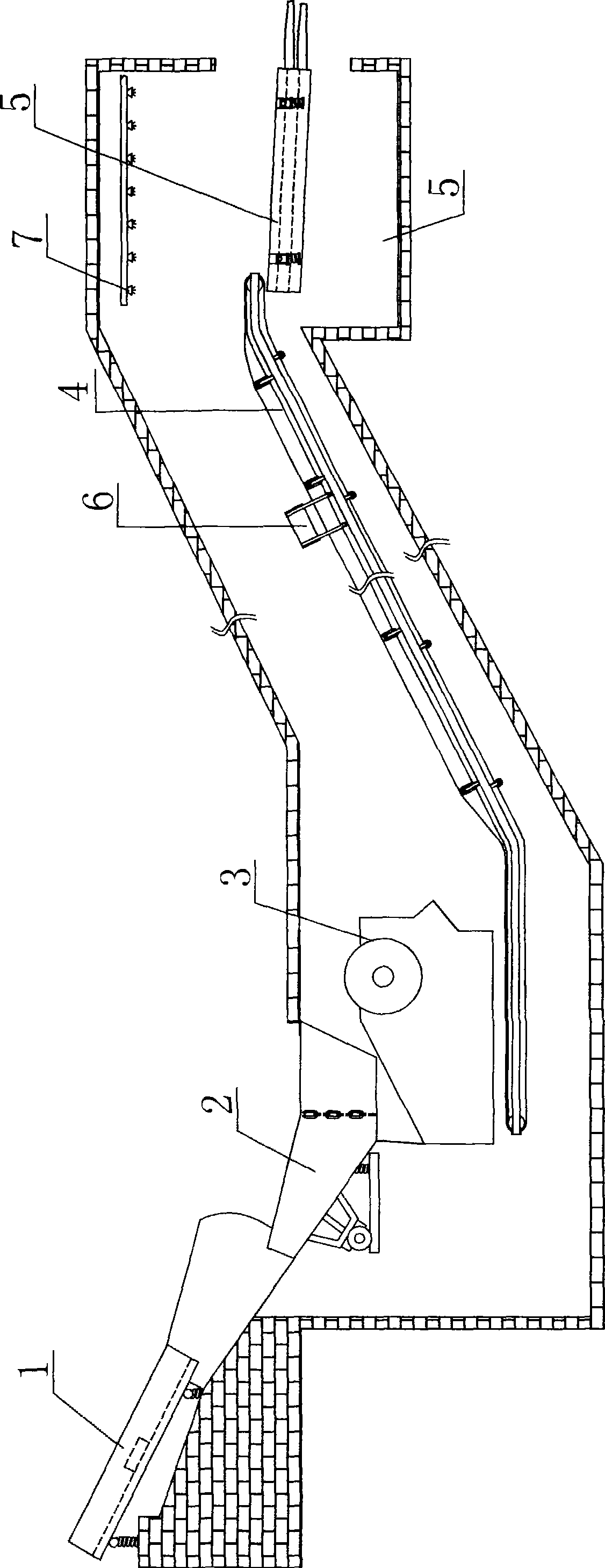

[0019] Such as figure 1 As shown, the present invention utilizes the construction waste whose main components are demolition of buildings, house renovation and road reconstruction, first properly crushes the construction waste and transports it to the treatment site, and then uses artificial methods to directly regenerate the construction waste The used substances, such as metal materials, wooden materials and plastic materials, are sorted and classified, and directly supplied to the corresponding companies for processing. Then, the recycled aggregate of the present invention is obtained through the steps of primary screening, feeding, crushing, conveying, sorting and secondary screening. Such as figure 2 As shown, the specific steps are as follows:

[0020] 1) Initial screening, the initial screening step is to separate the fine material contained in the construction waste through a single-stage vibrating screen 1, and this process will filter out about 10% of the soil con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com