Active free radical polymerization adjusting and controlling agent and preparation thereof

A technology of regulators and free radicals, applied in the field of macromolecules, can solve the problems of harsh preparation conditions, ineffective guarantee of yield, and complicated steps, and achieve the effects of mature production technology, low cost and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

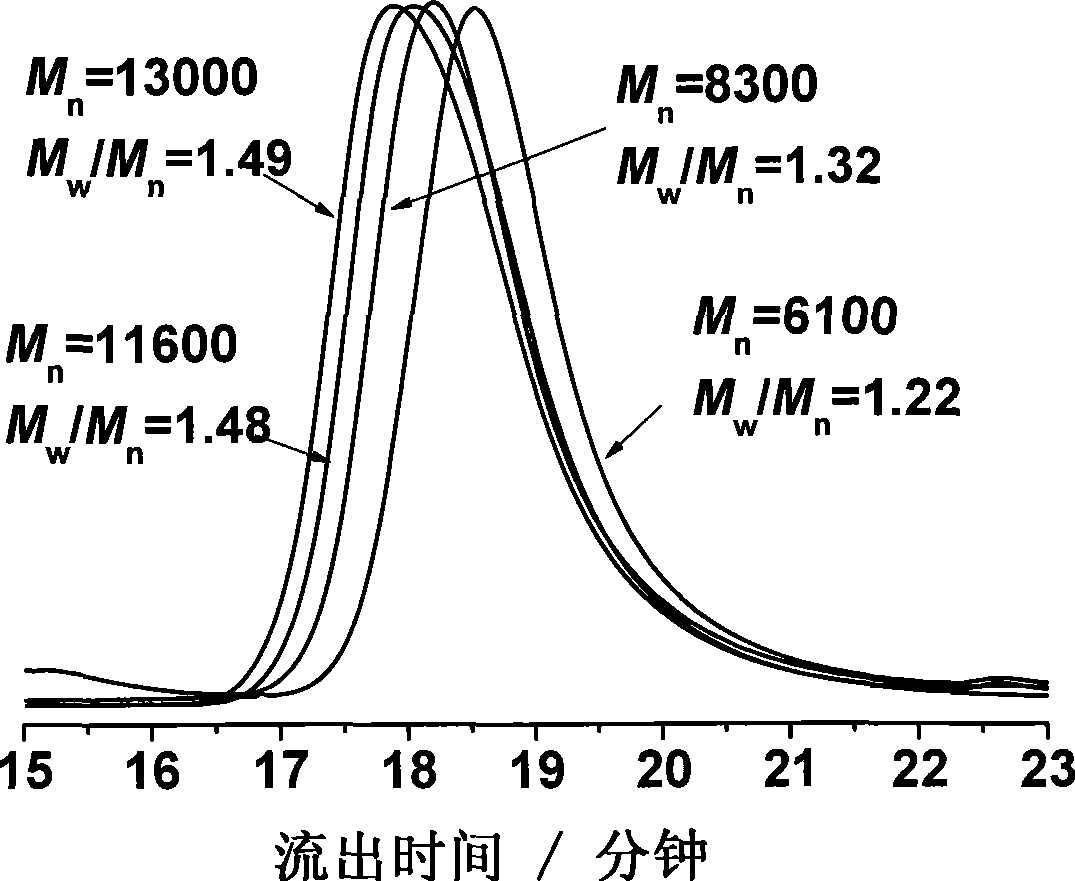

[0031] In a 100ml single-necked bottle, add azobisisobutyronitrile AIBN (0.3g, 1.8mmol), regulator DIP (0.5g, 1.8mmol), vinyl acetate (34ml, 0.36mol) and 20ml of benzene. After sealing, freeze-thaw and degas three times, and react at 60°C for 24 hours. Samples were taken regularly through a long needle, and the taken samples were quickly quenched in liquid nitrogen, and the molecular weight changes were observed by GPC after thawing. Experimental results such as figure 1 shown.

Embodiment 2

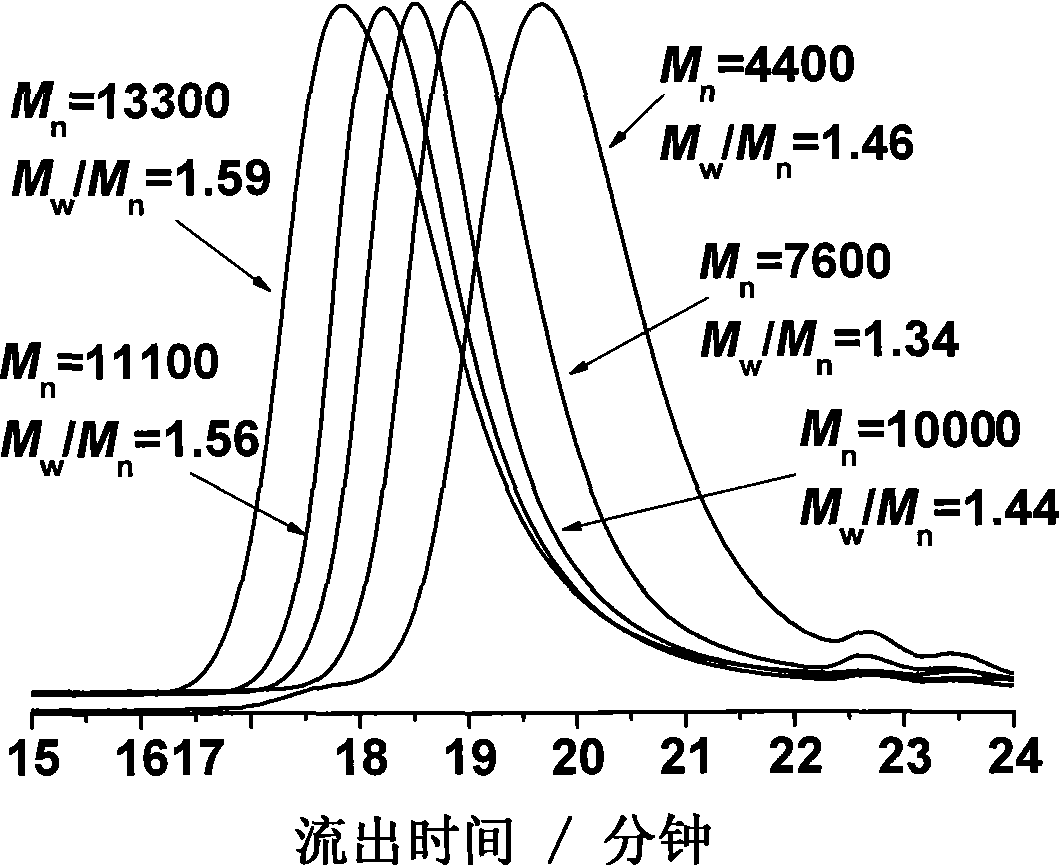

[0033] In a 150ml single-necked bottle, AIBN (0.45g, 2.4mmol), DIP (0.5g, 1.8mmol), vinyl acetate (50ml, 0.54mol) and 30ml of benzene were added. After sealing, freeze-thaw and degas three times, and react at 60°C for 30 hours. Samples were taken regularly through a long needle, and the taken samples were quickly quenched in liquid nitrogen, and the molecular weight changes were observed by GPC after thawing. Experimental results such as figure 2 shown.

Embodiment 3

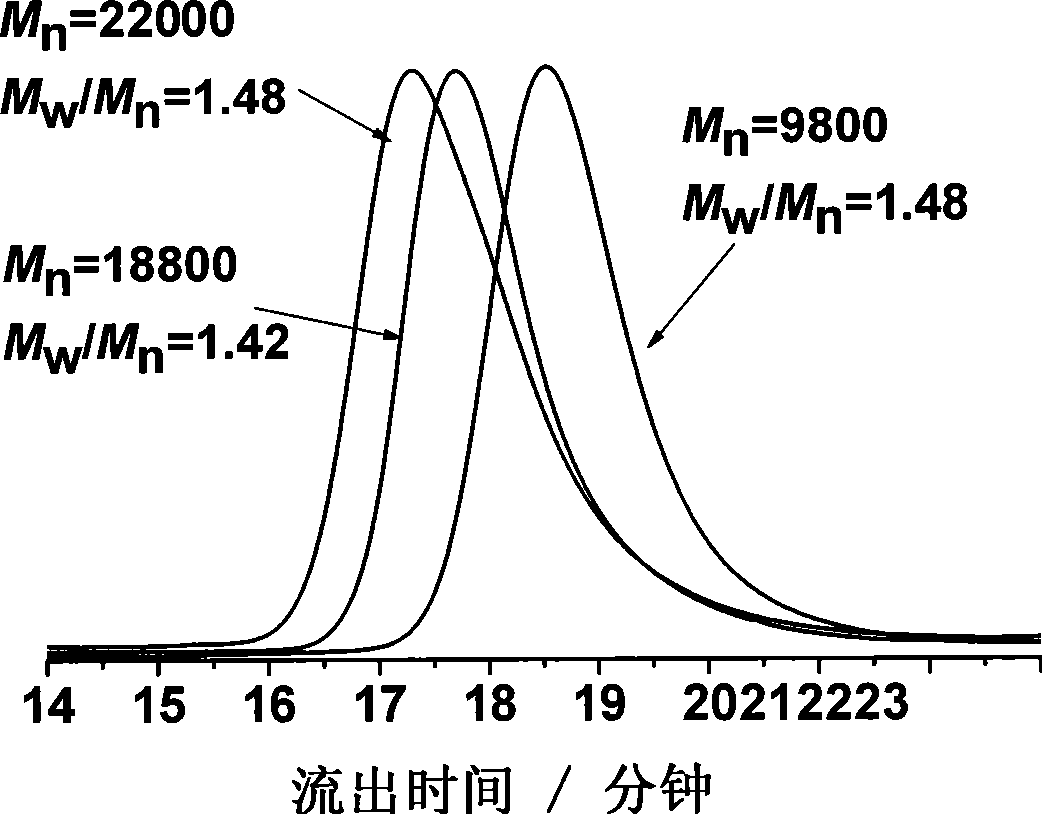

[0035] In a 250ml single-necked bottle, AIBN (0.6g, 3.6mmol), DIP (0.5g, 1.8mmol), vinyl acetate (60ml, 0.62mol) and 100ml of benzene were added. After sealing, freeze-thaw and degas three times, and react at 60°C for 18 hours. Samples were taken regularly through a long needle, and the taken samples were quickly quenched in liquid nitrogen, and the molecular weight changes were observed by GPC after thawing. Experimental results such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com