Method for controlling heating on edges of steel coil edge and heating device

A technology of edge heating and control method, applied in the field of finishing steel coil heating, can solve the problems of non-targeting, reduced steel mechanical properties, and high requirements for equipment installation space, and achieves simple equipment structure, small space occupation, and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

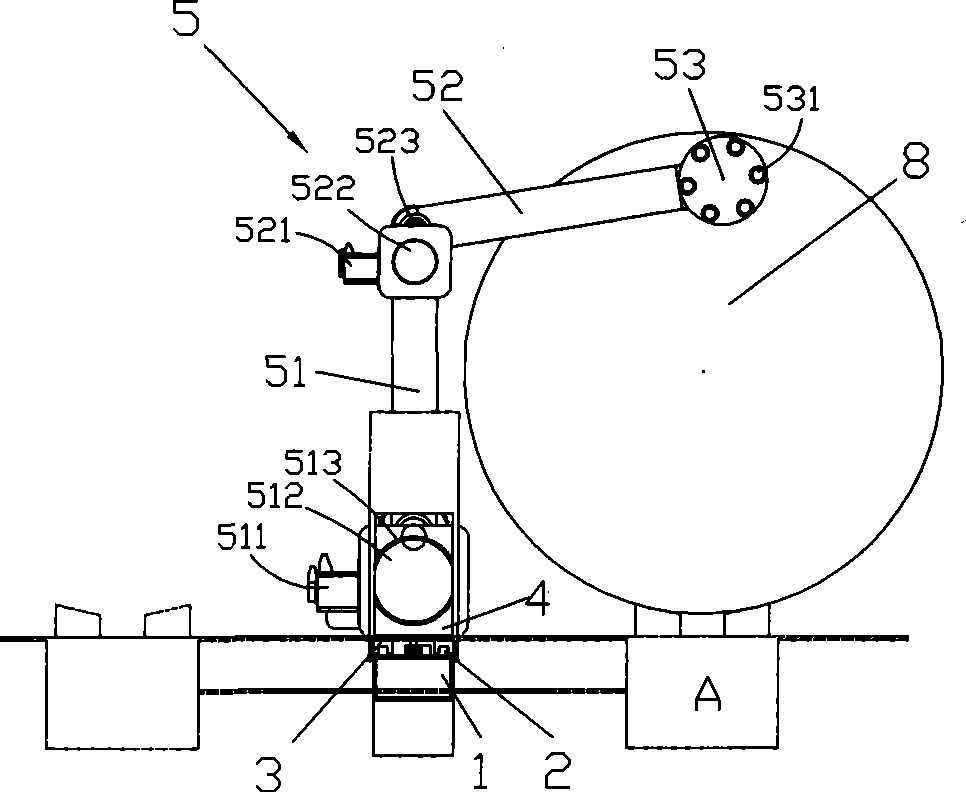

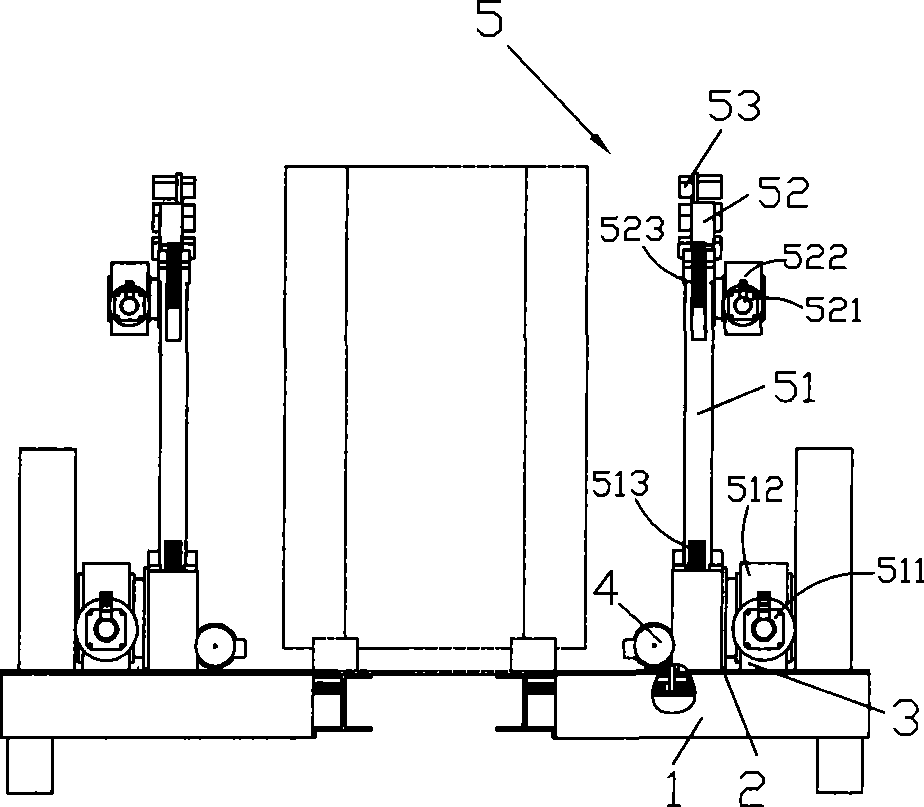

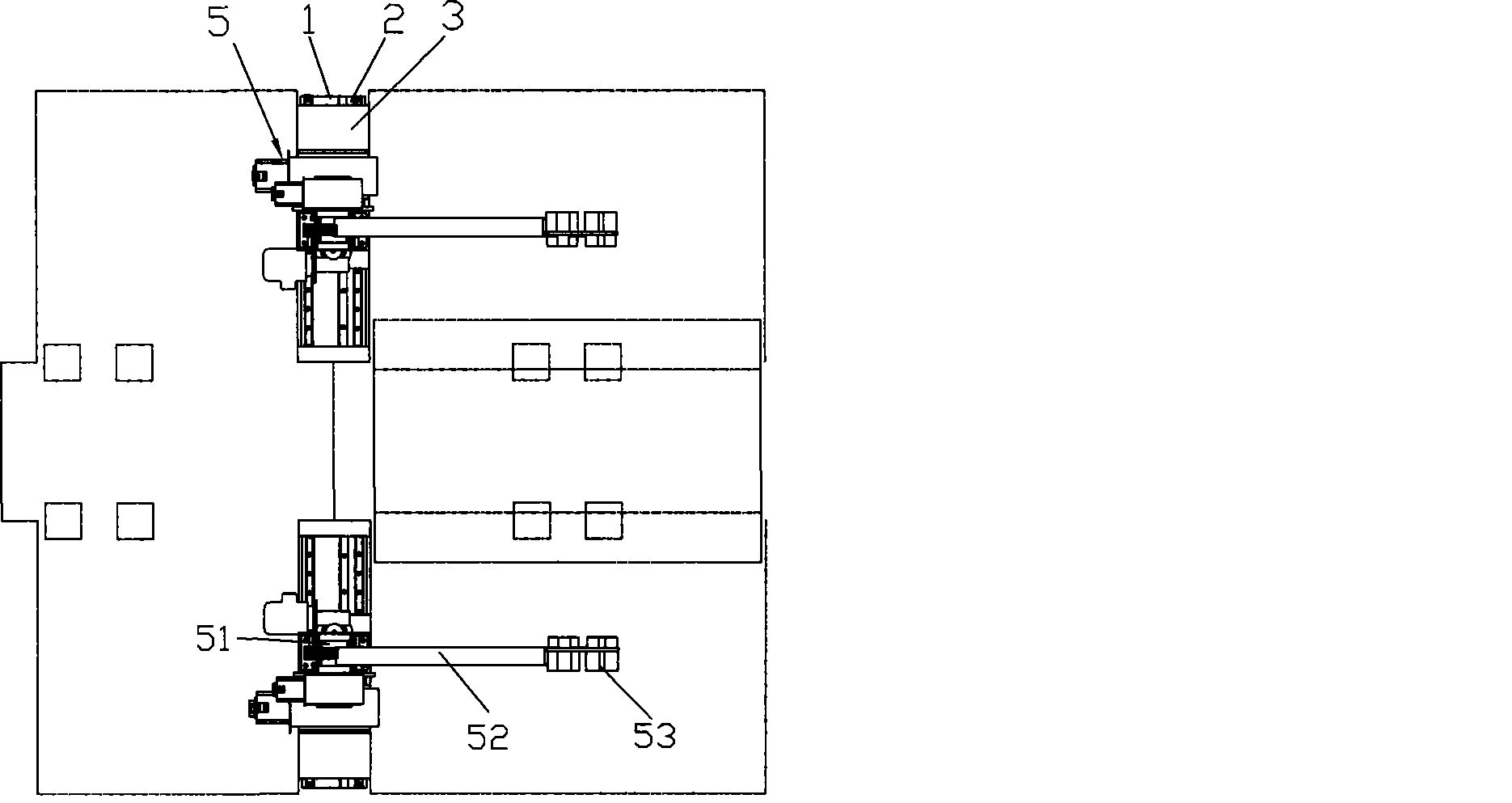

[0037] see Figure 1 ~ Figure 4 , the steel coil edge heating device related to the present invention is arranged at the heating stations A on the left and right sides of the steel coil 8, including a chassis 1 on which guide rails 2 are arranged; a moving bracket 3 is arranged on the chassis On the guide rail 2 of 1, front and rear driving devices 4 are arranged on it;

[0038]The gas heating mechanism 5 is arranged on the moving bracket 3, including a first mechanical arm 51 whose lower end is movably connected to the moving bracket 3, and is driven to rotate by the first servo motor 511, the reducer 512 and the corresponding gear 513 ; the second mechanical arm 52, one end of which is movably connected to the upper end of the first mechanical arm 51, and is driven to rotate by the second servo motor 521, the reducer 522 and the corresponding gear 523; the gas heating plate 53 is fixed on the second mechanical arm The outer end of 52 is provided with nozzle 531 and correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com