Device and method for measuring bursting temperature of pellet ores

A burst temperature, measuring device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that the burst temperature of pellets made by electric furnace cannot fully simulate production and other problems, achieve consistent test conditions, improve control accuracy, and high test efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

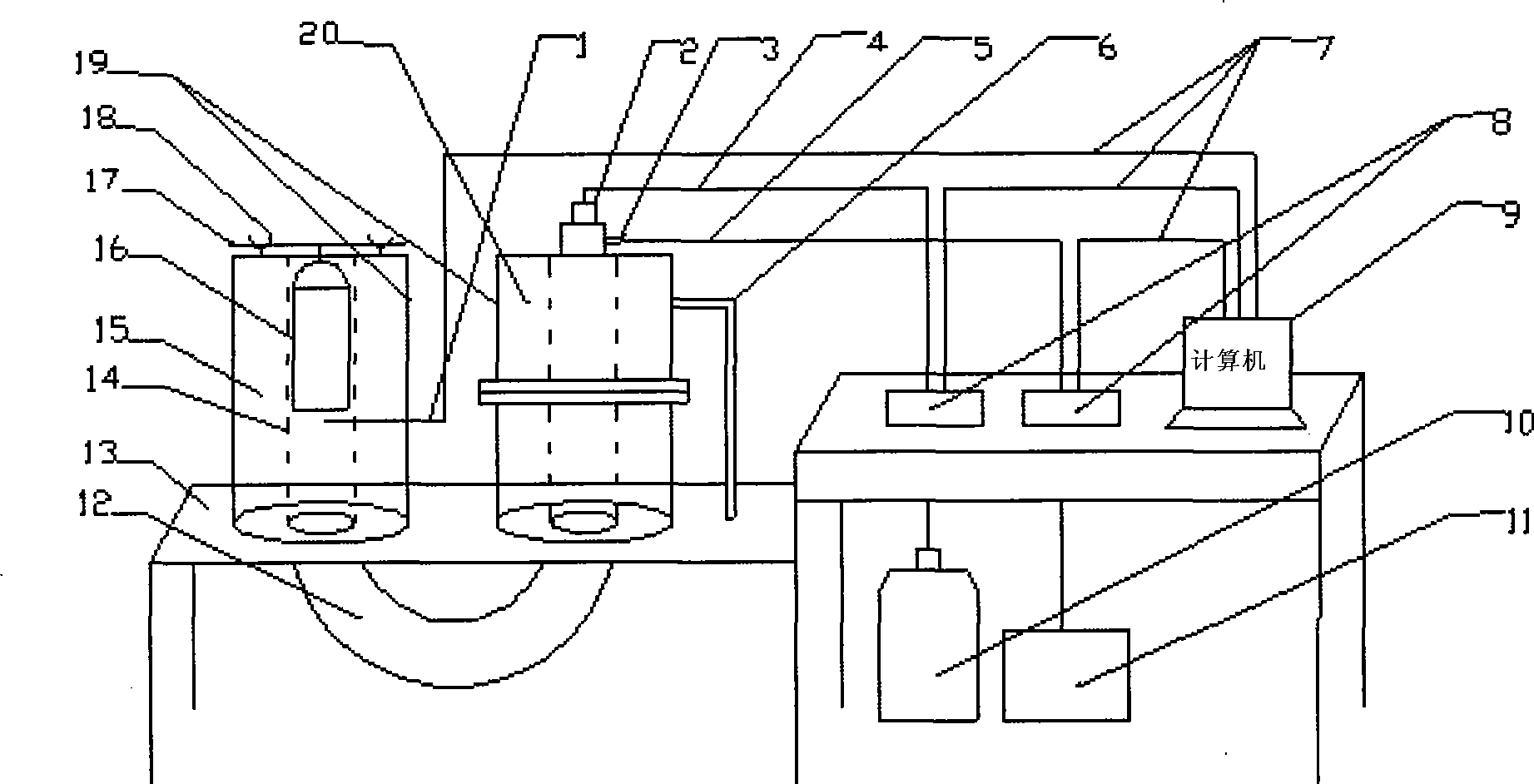

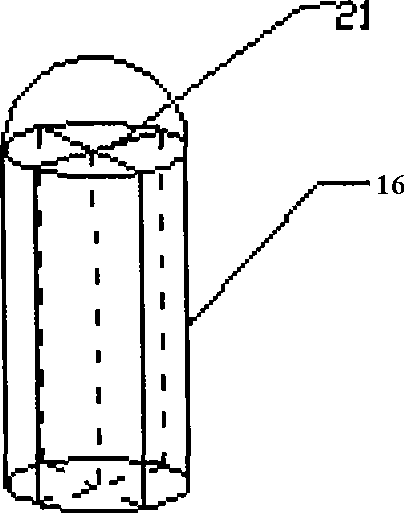

[0015] Such as figure 1 As shown, make a cylindrical cup 15, a cylindrical combustion chamber 20 and a cylindrical spider plant 16, the combustion chamber 20 is made into upper and lower parts, the upper part is fixed with a rotating rod 6, and the lower part of the combustion chamber 20 and the cup 15 are fixed on the test bench 13 , and connect the combustion chamber 20 bottom with the cup 15 with the U-shaped insulation pipe 12 . A refractory material tube 14 with a diameter slightly larger than the cylindrical spider plant 16 is fixed in the cup 15 and the combustion chamber 20, and the space between the steel shell 19 and the refractory material tube 14 is filled with thermal insulation material, and two support seats 18 are fixed on the cup 15. The spider plant 16 of good sample is suspended in cup 15 with steel rod 17. A thermocouple 1 is inserted into the side position of the cup 15, and the temperature of the thermocouple 1 is sent to the computer 9 with a data line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com