Machining simulation apparatus

A technology for simulating equipment and processing tools, applied in metal processing equipment, simulators, metal processing and other directions to achieve the effect of reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

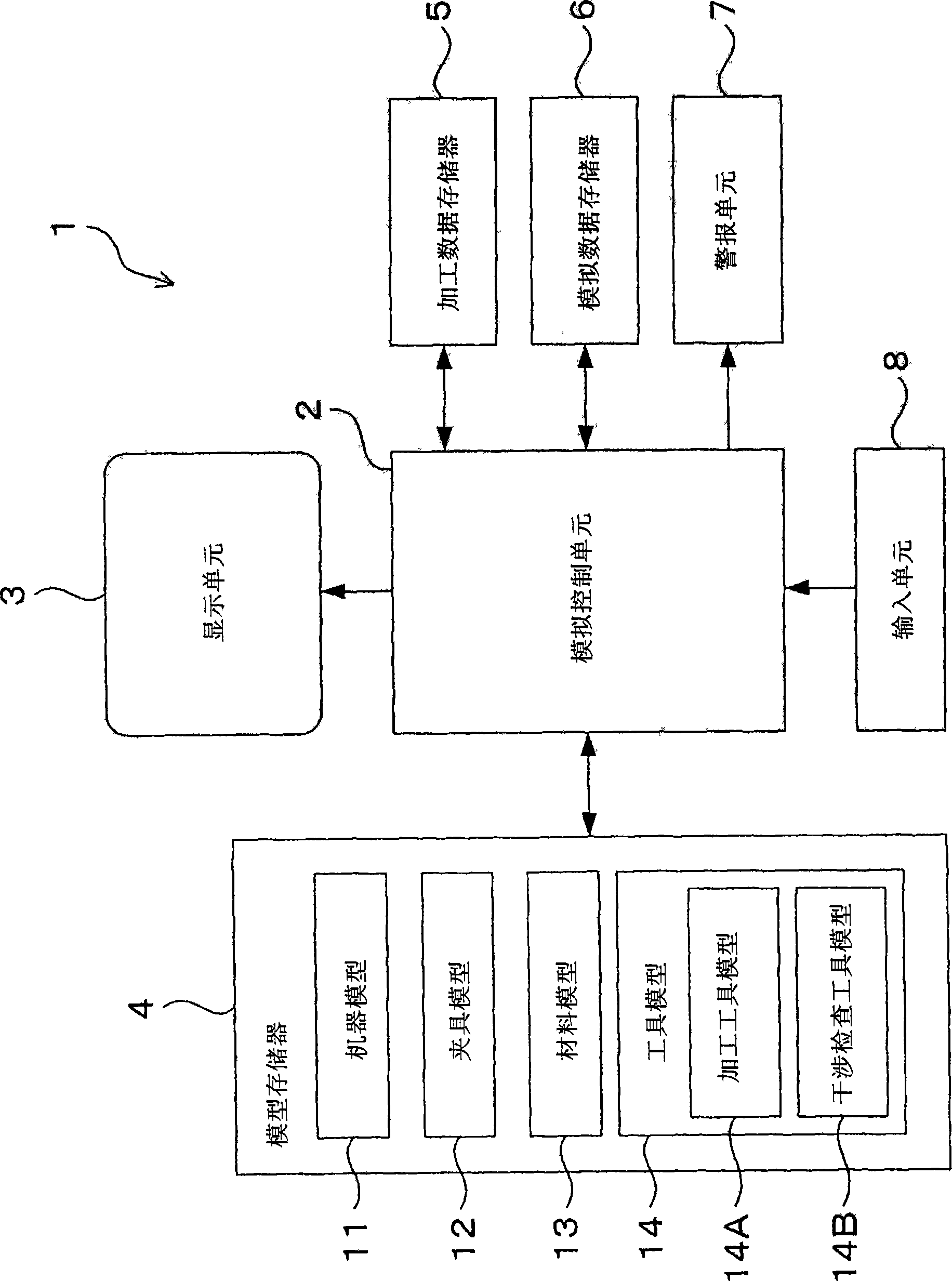

[0029] Embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 The overall configuration of the machining simulation apparatus 1 for a machine tool is schematically shown. The processing simulation device 1 includes: a simulation control unit 2, which is used to control all operations of the device 1; a display unit 3, which is used to show a simulation screen; a model memory 4, which is used to store various models; a processing data memory 5 , which is used to store processing data, including NC programs and manual axis movement instructions; simulation data memory 6, which is used to store programs and parameters for simulation; alarm unit 7, which is used to an alarm at the time of interference; and an input unit 8 manipulated by an operator to input various inputs.

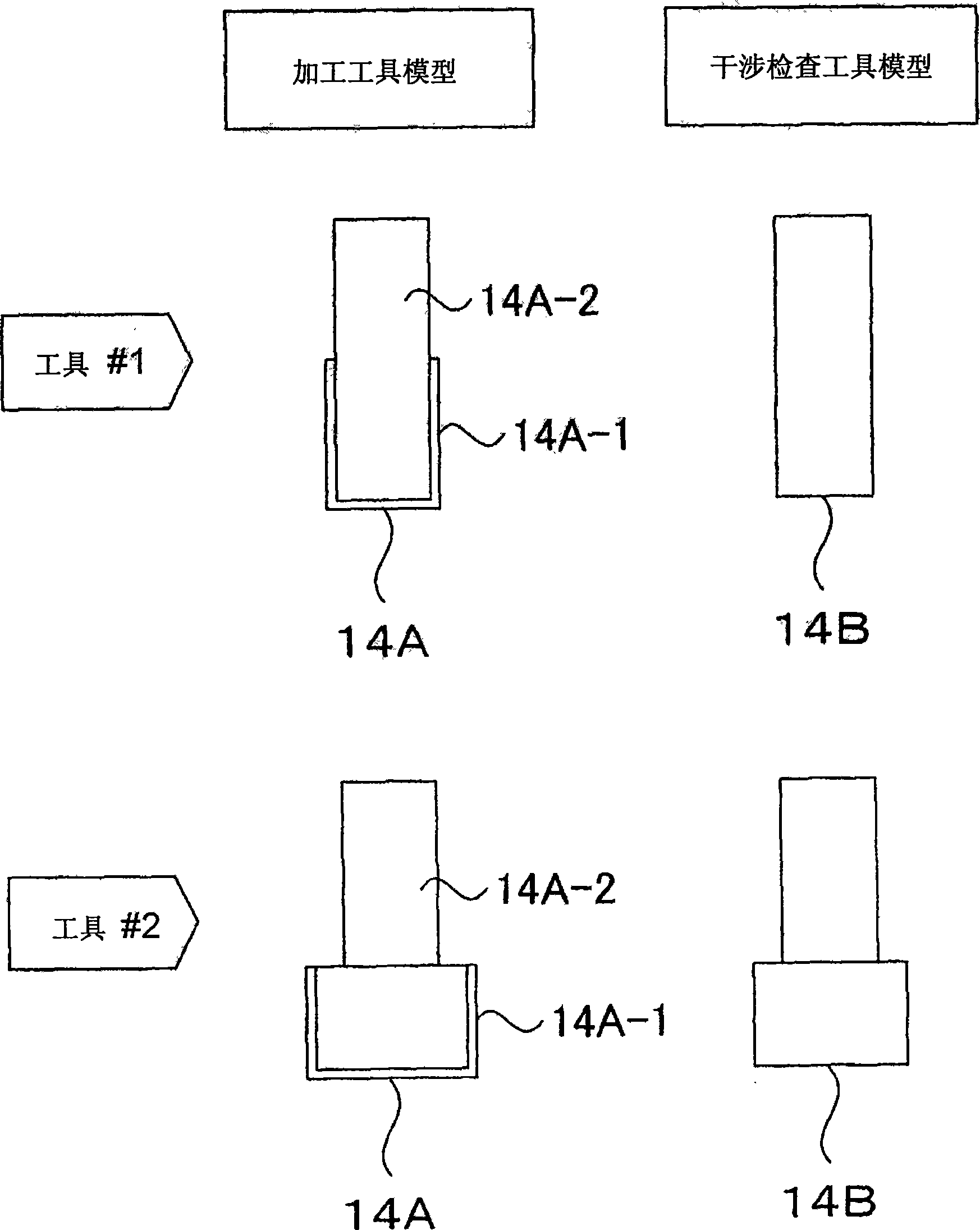

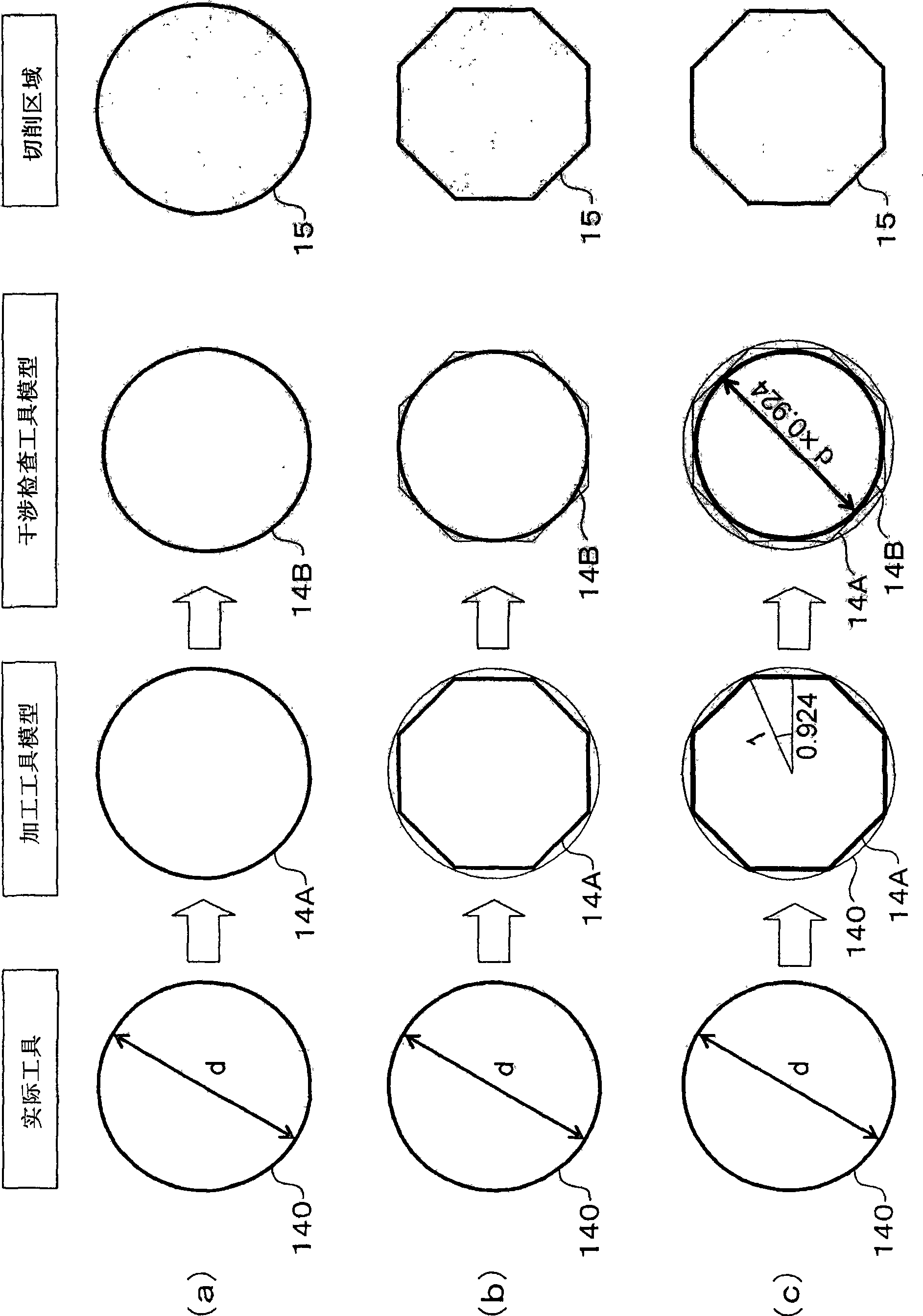

[0030] The model memory 4 stores: a machine model 11 that defines mechanical elements such as spindle heads and tables; a fixture model 12 that def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com