Method for manufacturing TFT-LCD array substrate and color film substrate

A manufacturing method and an array substrate technology, which are applied in the photolithographic process of the patterned surface, semiconductor/solid-state device manufacturing, instruments, etc., can solve the problems of many production processes, long time, and reduced TFT-LCD production efficiency, etc., and achieve improved Production efficiency, the effect of guaranteeing product characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

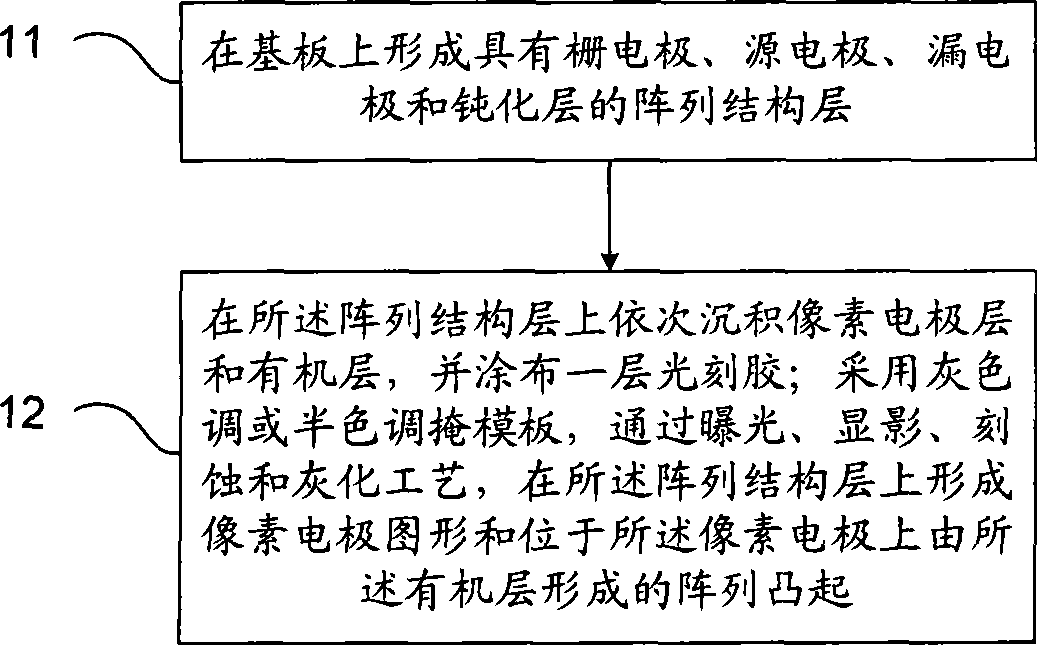

[0065] figure 1 It is a flow chart of the manufacturing method of the TFT-LCD array substrate of the present invention, specifically:

[0066] Step 11, forming an array structure layer having a gate electrode, a source electrode, a drain electrode and a passivation layer on the substrate;

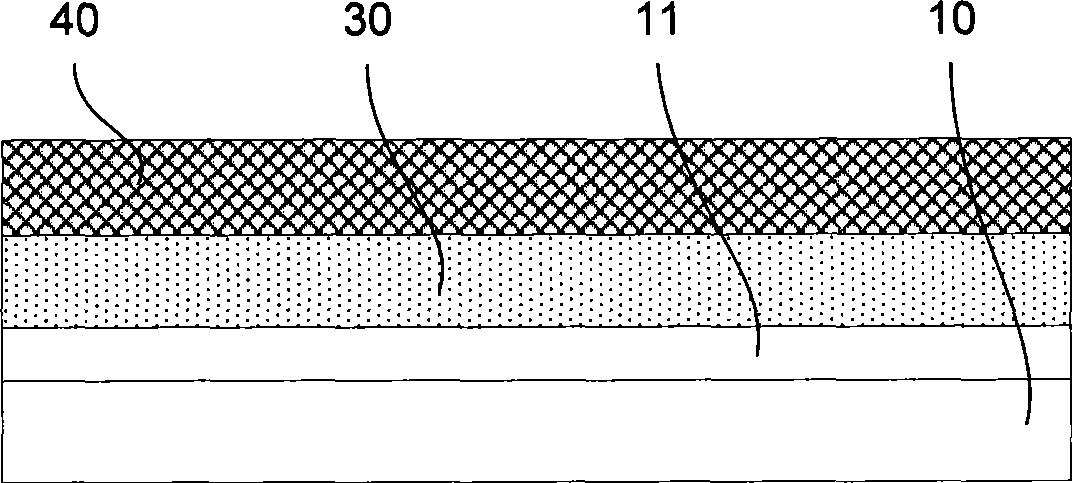

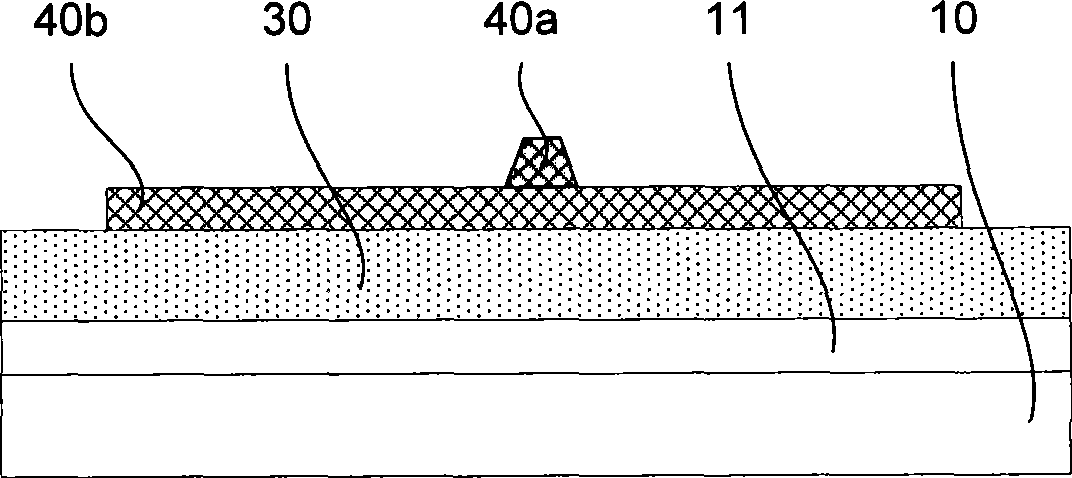

[0067] Step 12, sequentially depositing a pixel electrode layer and an organic layer on the array structure layer, and coating a layer of photoresist; using a gray-tone or half-tone mask, through exposure, development, etching and ashing processes, the A pixel electrode pattern and an array protrusion formed by the organic layer on the pixel electrode are formed on the array structure layer.

[0068] The invention provides a method for manufacturing a TFT-LCD array substrate based on the MVA mode. By using a gray tone or half tone mask, the two patterning processes for forming pixel electrodes and array protrusions in the prior art are integrated into one patterning process. , while impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com