Production method of polyaluminium chloride

A polyaluminum chloride and production method technology, applied in the direction of aluminum chloride, aluminum halide, solid waste removal, etc., can solve the problems of unfavorable environment and resource protection, achieve favorable environment and resource protection, reduce production costs, and effectively Conducive to the effect of environment and resource protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

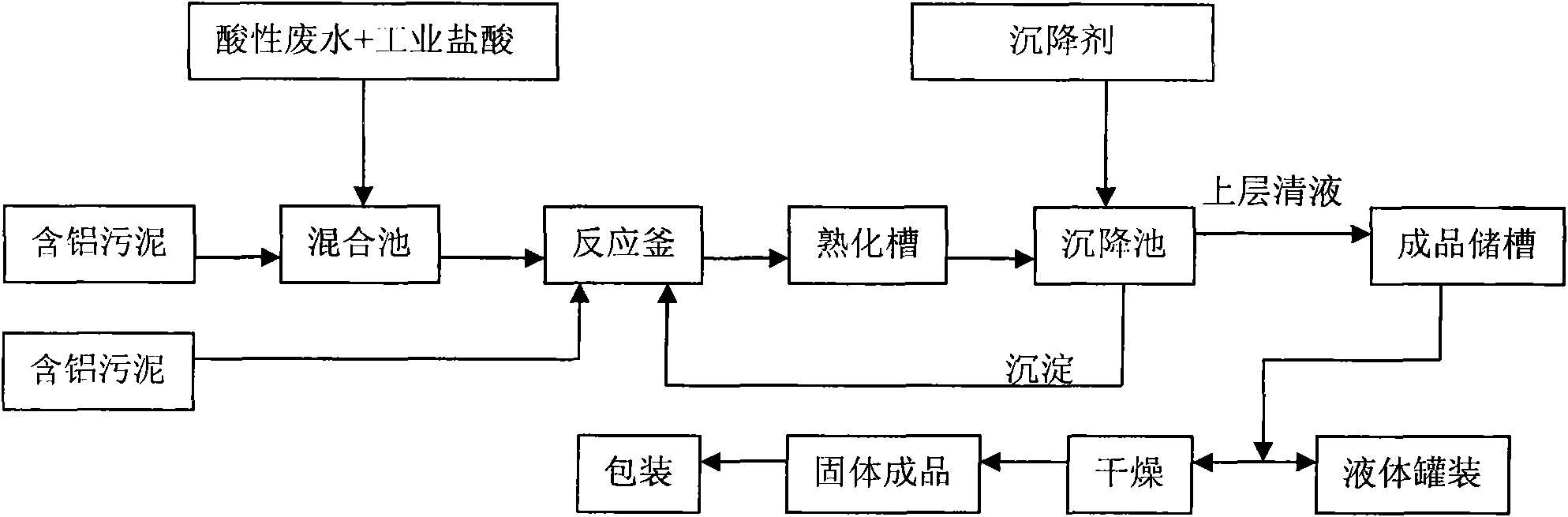

Method used

Image

Examples

Embodiment 1

[0022] Acidic waste water (acidity is 10%) is mixed with industrial hydrochloric acid (acidity is 31%) in a mass ratio of 1:1 to obtain HCl solution, and aluminum-containing sludge (Al 2 o 3 content is about 12%) and HCl solution reacted in the mixing pool for 6 hours with the mass ratio of 1.12:0.53, and the acidity obtained was 10.5%, Al 2 o 3 The reaction mother liquor with a content of 8.0%, a small amount of HCl gas escapes during this process, and the HCl gas becomes a washing liquid with an acidity of 15-20% after being absorbed by acid mist, and the washing liquid is circulated to the mixing tank to participate in the reaction, acid mist absorption system They are topped up with fresh tap water.

[0023] The reaction mother liquor and aluminum-containing sludge are reacted in the reactor at a mass ratio of 265:70, the reaction pressure: 0.2-0.4MPa, the reaction temperature: 110-120°C, the reaction time: 3h, and then the reaction mixture in the reactor is transferred ...

Embodiment 2

[0030] Acidic wastewater (acidity 19%) was used as HCl solution, aluminum-containing sludge (Al 2 o 3 content is about 14%) and HCl solution with the mass ratio of 1:0.5 reacted in the mixing pool for 8 hours, and the acidity was 9%, Al 2 o 3 The reaction mother liquor with a content of 9.0%, a small amount of HCl gas escapes during this process, and the HCl gas becomes a washing liquid with an acidity of 15-20% after being absorbed by the acid mist, and the washing liquid is circulated to the mixing tank to participate in the reaction, the acid mist absorption system They are topped up with fresh tap water.

[0031] The reaction mother liquor and aluminum-containing sludge are reacted in the reactor at a mass ratio of 1:0.3, the reaction pressure: 0.2-0.4MPa, the reaction temperature: 110-120°C, the reaction time: 4h, and then the reaction mixture in the reactor is transferred Transfer to the aging tank, after aging for 24 hours, transfer to the settling tank, add a settli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com