Calcination-free desulfurized gypsum dry mixed mortar

A technology for desulfurized gypsum and dry-mixed mortar, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low storage, large investment, huge supporting facilities, etc., and achieves low cost and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 (interior wall plastering dry-mixed mortar):

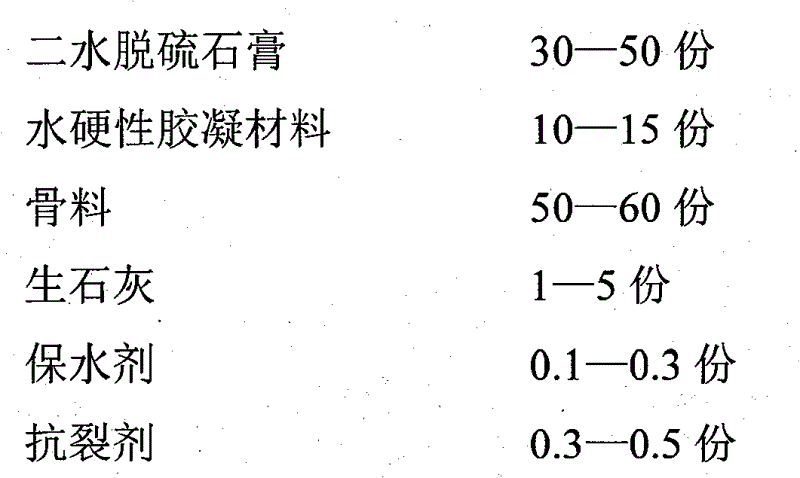

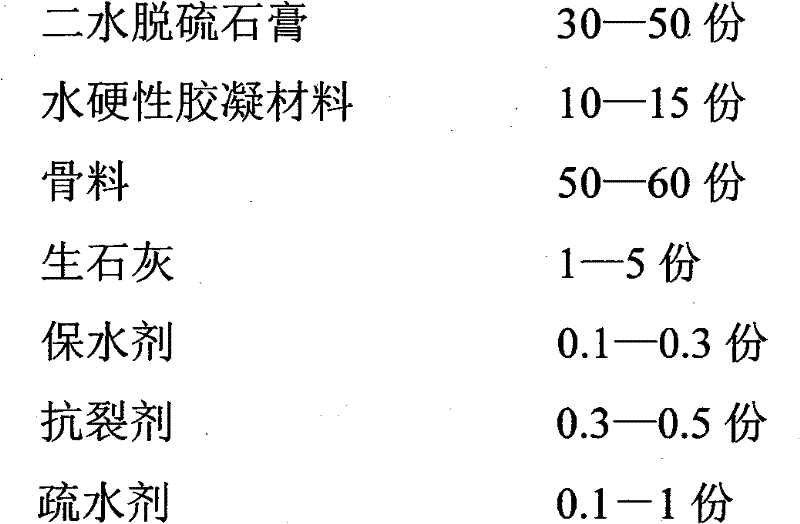

[0033] formula:

[0034] Dihydrate desulfurized gypsum (40 mesh): 40Kg Ordinary Portland cement: 12Kg

[0035] Construction sand: 55Kg (fineness less than 4mm) quicklime: 2Kg

[0036] Methylcellulose: 0.2Kg Wood fiber: 0.4Kg

[0037] Preparation:

[0038] After accurately measuring various raw materials according to the above formula, mix and force mechanical stirring to obtain the target product.

Embodiment 2

[0039] Embodiment 2 (external wall plastering dry-mixed mortar):

[0040] formula:

[0041] Dihydrate desulfurized gypsum (40 mesh): 40Kg Ordinary Portland cement: 12Kg

[0042] Construction sand: 55Kg (fineness less than 4mm) quicklime: 2Kg

[0043] Methylcellulose: 0.2Kg Wood fiber: 0.4Kg

[0044] Polymer redispersible powder: 0.6Kg

[0045] Preparation:

[0046] After accurately measuring various raw materials according to the above formula, mix and force mechanical stirring to obtain the target product.

[0047] During the construction process, the water consumption shall be calculated according to the standard water consumption with a slurry diffusion diameter of 150±5mm. Before construction, the wall surface should be fully wet, and the materials should be fully mixed evenly, so as to produce better strength.

[0048] According to the standard method used by my country's construction industry, the technical performance test results of the above-mentioned embodiment...

Embodiment 3

[0050] Embodiment three (interior wall plastering dry-mixed mortar):

[0051] formula:

[0052] Dihydrate desulfurized gypsum (40 mesh): 45Kg Fly ash: 14Kg

[0053] Water-quenched slag: 52Kg (fineness less than 4mm) Quicklime: 3Kg

[0054] Hydroxyethyl methylcellulose: 0.4Kg Polyacrylonitrile fiber: 0.4Kg

[0055] Preparation:

[0056] After accurately measuring various raw materials according to the above formula, mix and force mechanical stirring to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com