Hoisting system of stripper well in oil field

A technology for low-yield wells and oil fields, applied in drilling equipment, wellbore/well components, and production fluids, etc., can solve the problems of poor implementation of wire rope sucker rods, poor sealing effect of dynamic seal wellheads, and small adjustment range of stroke, etc. The effect of light and miniaturized safe operation, reduced maintenance cost, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

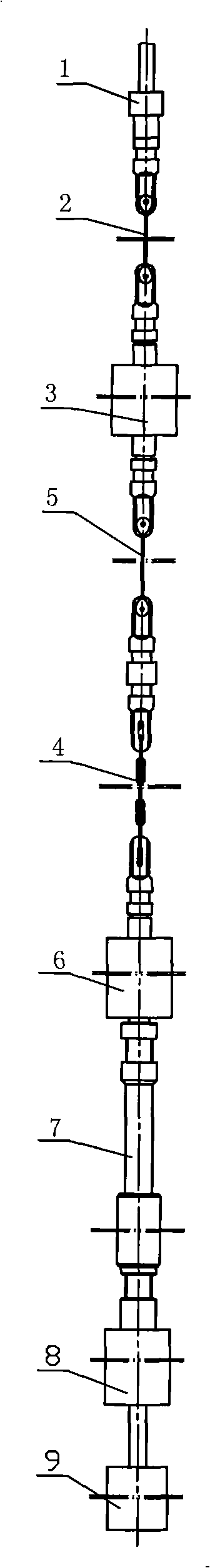

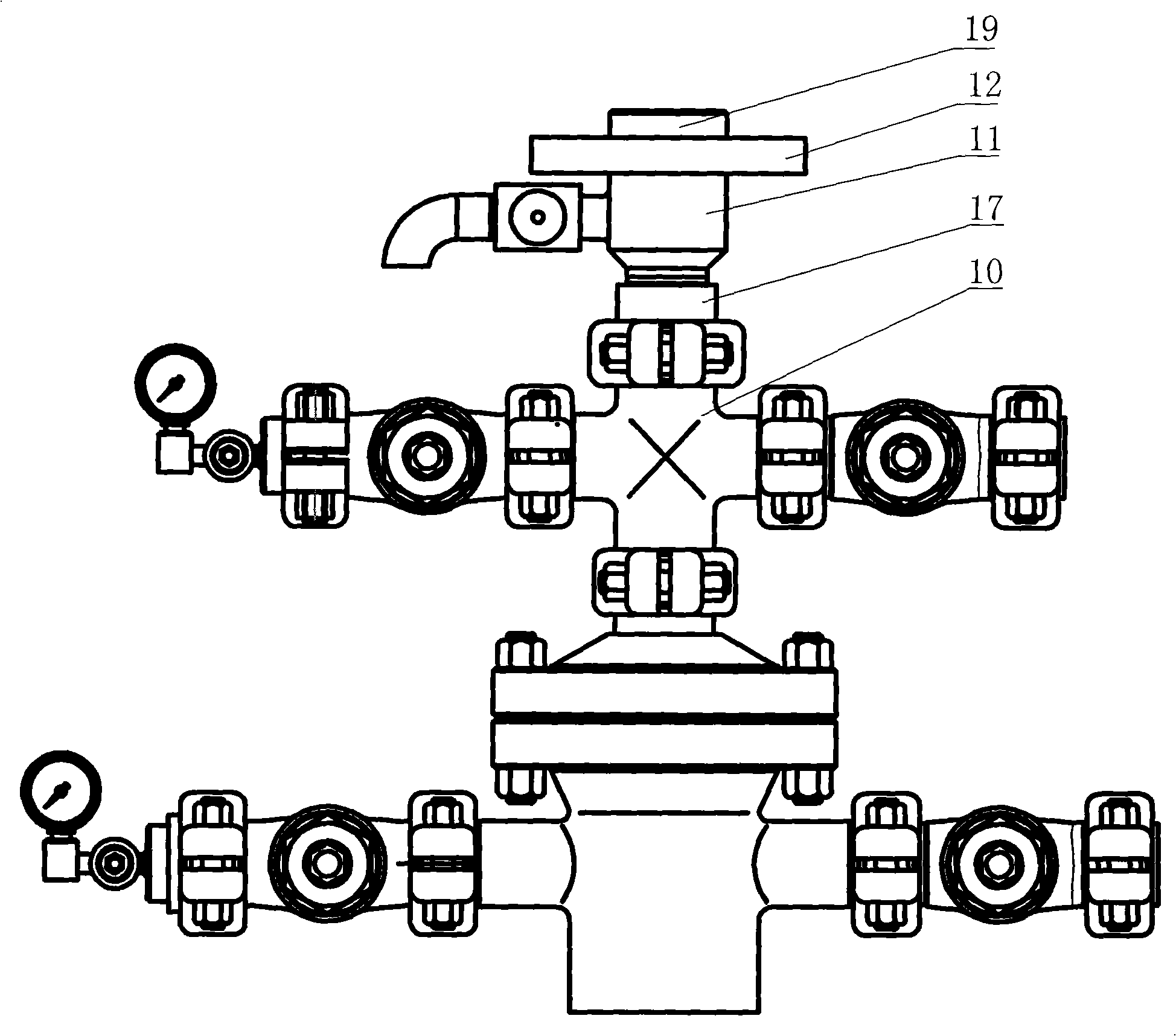

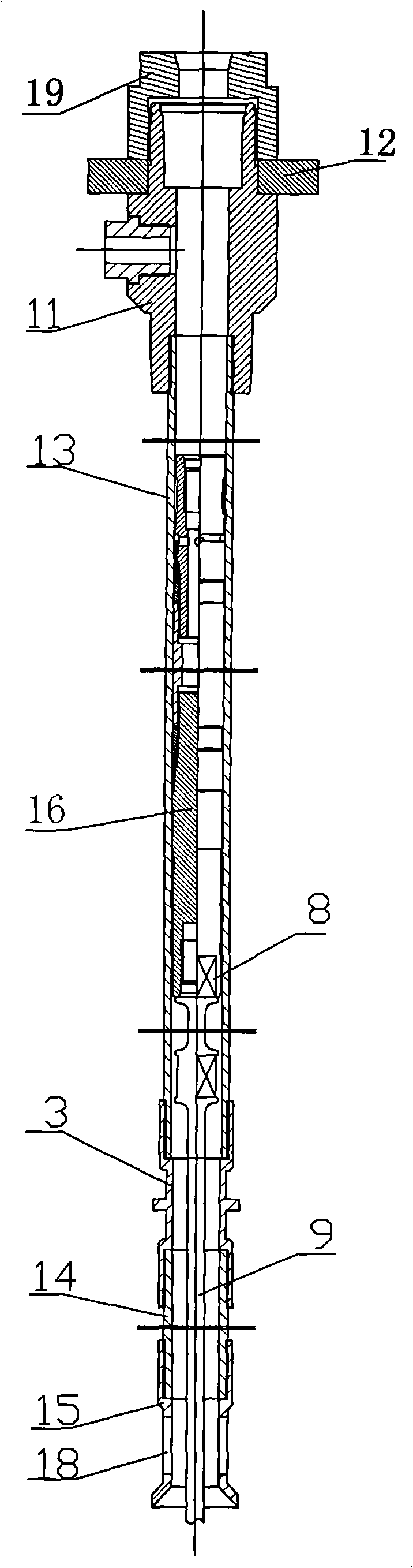

[0020] Depend on figure 1 combine figure 2 , image 3 As shown, the low-production well lifting system in this oilfield includes a double-range flexible pumping unit, a double-range flexible pumping unit wellhead and a composite functional unit sucker rod string.

[0021] Depend on figure 1 As shown, the composite functional unit sucker rod string is composed of adjustment short connection 1, composite steel wire rope 2, upper weighted rod 3, fiber rope 5, ring chain 4, middle weighted rod 6, vibration rod 7, lower weighted rod 8 And pull rod 9 is formed in series successively. The main purpose of using composite steel wire rope 2 for the pole column is to reduce dead weight. In order to ensure the safe and reliable implementation of the composite steel wire rope 2, the upper weighted rod 3, the ring chain 4, the fiber rope 5, the middle weighted rod 6, the vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com