Apparatus for measuring density and pH value of serous fluid processed by wet flue gas desulfurization

A technology for wet flue gas desulfurization and measuring devices, which is applied in the direction of measuring devices, instruments, scientific instruments, etc. It can solve the problems that density meters and pH meters cannot be flushed online, affect measurement accuracy, and equipment shutdowns, etc., and achieve easy online flushing and maintenance, reduce the frequency of accidents, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

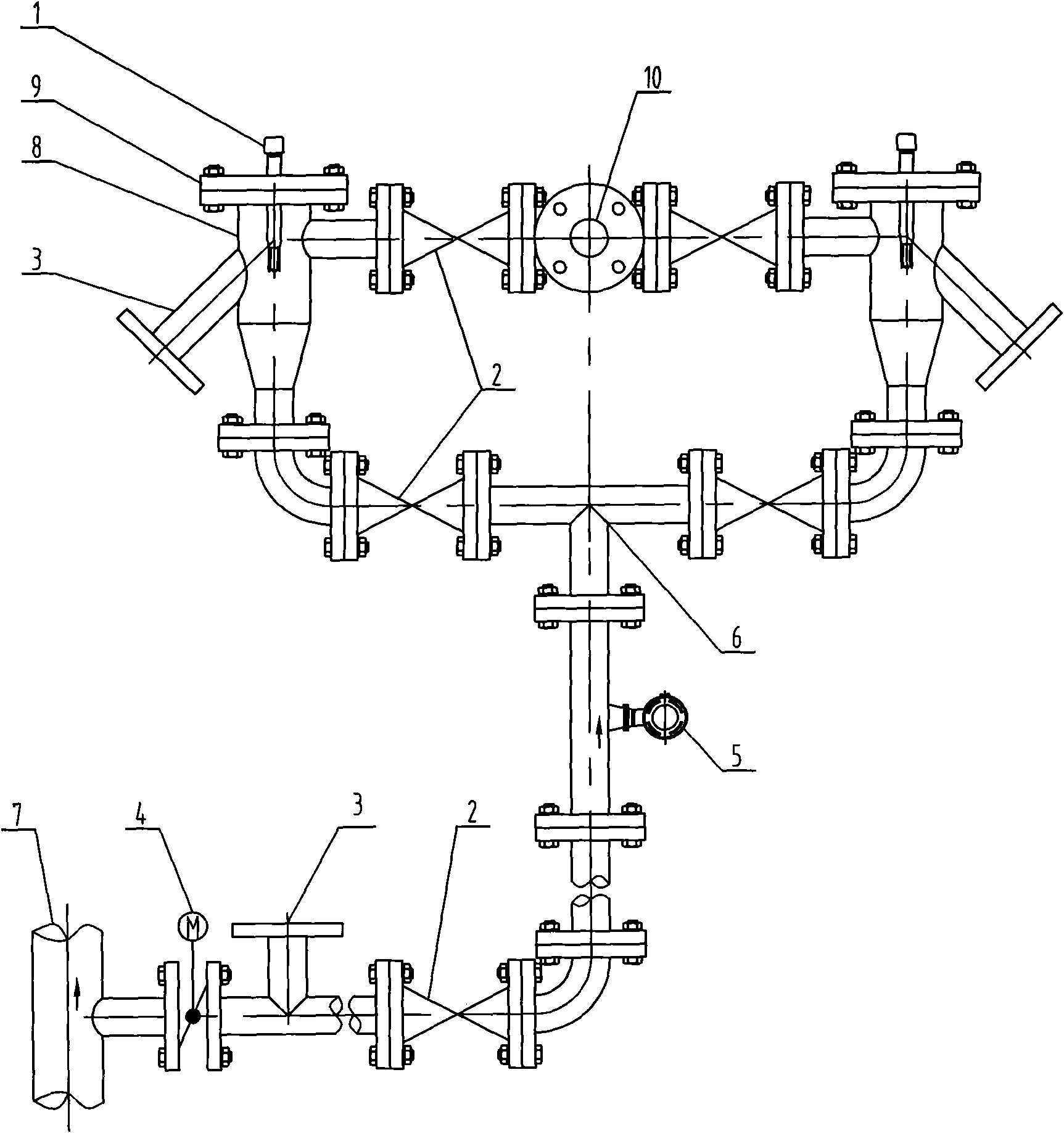

[0009] according to figure 1 The specific structure of the present invention will be described in detail. The wet flue gas desulfurization slurry density and pH value measuring device includes a main pipeline 7 and a density meter (mass flow meter / density meter) 5 for measuring the slurry, a pH meter 1, a return pipeline 10, a plurality of connecting flanges 9, and a diaphragm valve 2 and bent pipe, parts such as clip electric valve 4 and support cylinder 8. Wherein the main pipeline 7 for conveying gypsum slurry and limestone slurry is provided with a branch pipe, and through the branch pipe and the connecting flange 9, the elbow will sequentially communicate with the electric valve 4, the diaphragm valve 2 and the support cylinder 8, and then communicate with the will be The return pipeline 10 that measures the slurry and sends it into the slurry buffer tank forms a slurry circulation loop. Diaphragm valve 2 is set for closing local branch pipelines when the density meter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com