An electric motor control device and an electric motor control system

A control device and motor technology, applied in motor control, motor generator control, AC motor control, etc., can solve problems such as calculation errors, low recognition accuracy, and low dynamic range of values, and achieve the effect of suppressing overflow calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

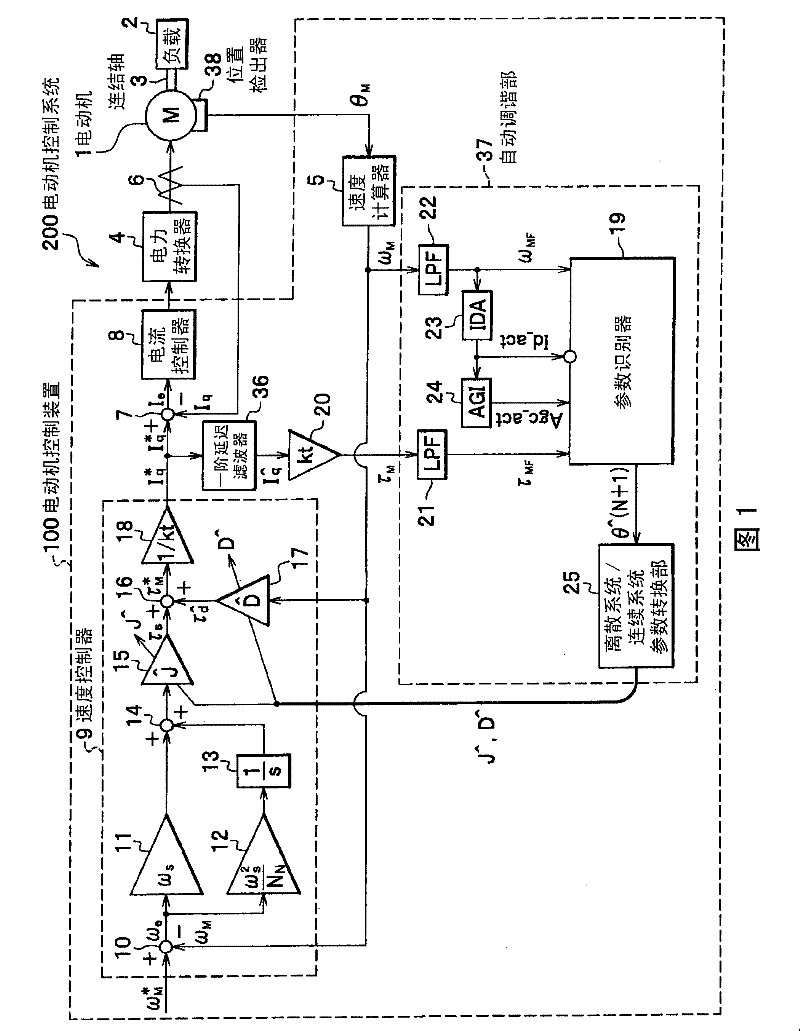

[0175] use figure 1 A configuration diagram of a motor control system as a first embodiment of the present invention will be described.

[0176] exist figure 1 Among them, the motor control system 200 includes: a motor 1; a load 2 driven by the motor 1 (a load to be driven); a connecting shaft 3 connecting the motor 1 and the load 2; a power converter 4 for driving the motor 1; On the rotating shaft, output the position detection value θ of the rotating shaft of the motor 1 M The position detector 38; the current detector 6 that detects the current flowing into the motor 1; and the motor control device 100.

[0177] The motor control device 100 includes: a speed calculator 5; a current controller 8; a first-order delay filter 36; a torque constant amplifier 20; an automatic tuning section 37; a discrete system / continuous system parameter conversion section 25; a speed controller 9; Subtractor 7, their functions are realized by computers such as CPU and programs. Furthermor...

no. 2 Embodiment approach

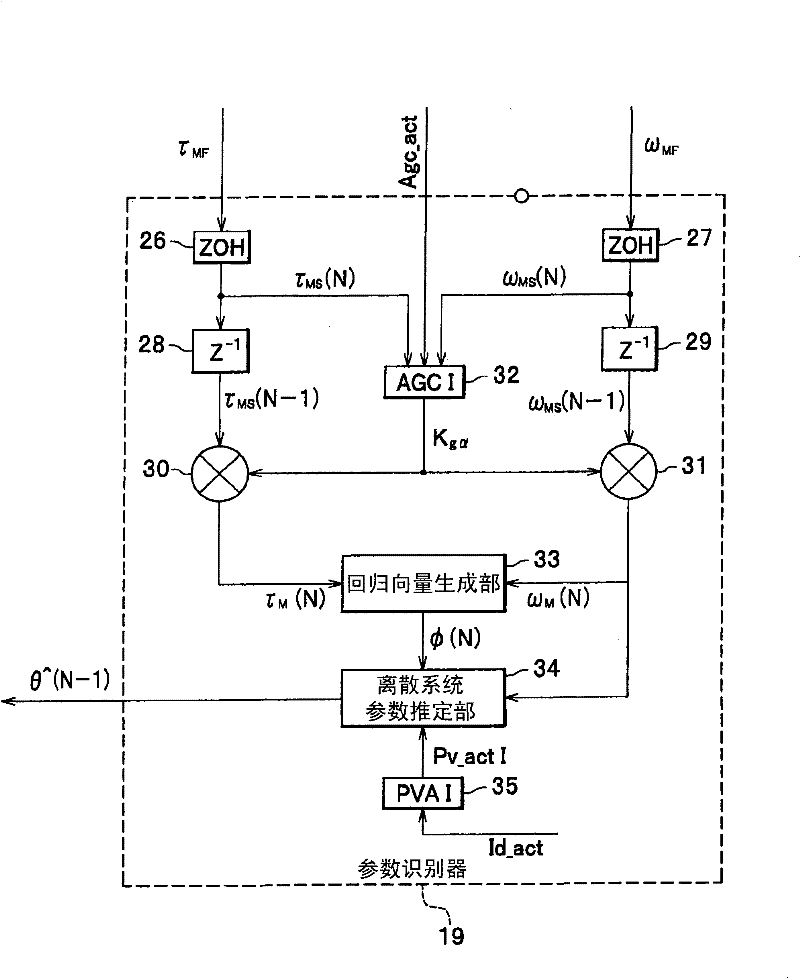

[0305] Next, use Figure 18 , the parameter recognizer according to the second embodiment of the present invention will be described. and figure 2 The parameter identifier 19 shown differs in that the attenuation gain K gα Multiply this point with the regression vector. In addition, the configuration of the motor control system is the same as that of the first embodiment figure 1 same.

[0306] The regression vector generation unit 351 inputs τ according to the formula (62) MS (N) and ω MS (N), generate regression vector Φ * (N). Multiplier 353, the attenuation gain K outputted by automatic gain control section 352 (AGC2) gα and regression vector Φ * (N) are multiplied, and the operation result is output as a regression vector Φ(N). The multiplier 354 will attenuate the gain K gα with ω MS (N) are multiplied, and the operation result is taken as ω M (N) output.

[0307] The discrete system parameter estimation unit operation signal generator 355 (PVA2) outputs I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com