Automatic food rolling machine

A technology for rolling press and food, which is applied in the directions of food preparation, food forming, food science, etc., can solve the problems of difficulty in ensuring safety and hygiene, and the taste of finished products is not uniform, and achieves a simple structure, meets the needs of life, and has a stable taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

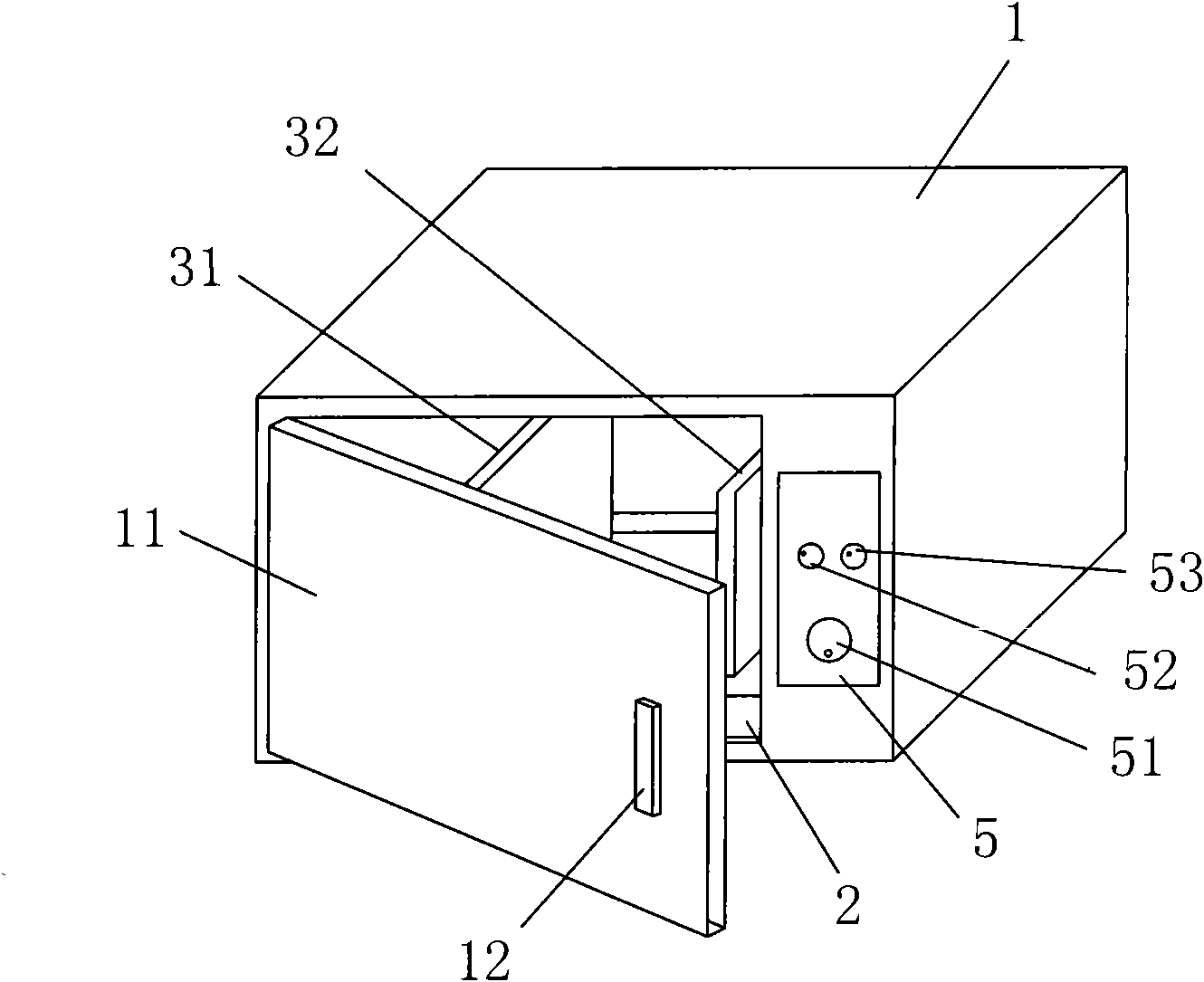

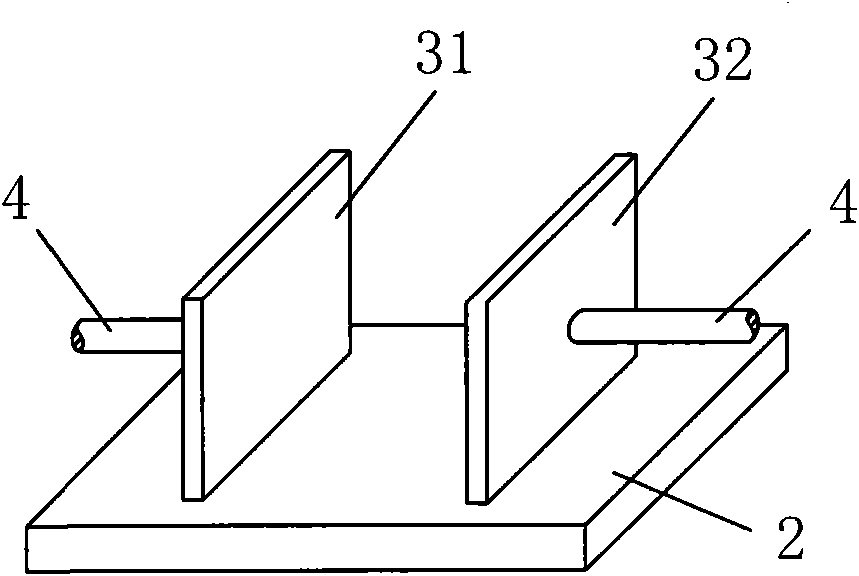

[0024] Such as figure 1 As shown, it is a schematic diagram of the overall structure of an embodiment of the automatic food rolling press of the present invention. The automatic food rolling press includes a closed box body 1, on which a side door 11 is installed, and a handle 12 is installed on the side door 11 to facilitate opening. Such as figure 2 As shown, the automatic food rolling press also includes: a plate-shaped base plate 2, which is fixed on the inner bottom surface of the box body 1; two plate parts 31, 32, which are perpendicular to the plane of the base plate 2, and symmetrical The sub-sets are erected on both sides above the base plate 2, and the flat parts 31, 32 are connected to a power part 4, and are controlled by the power part 4 to move above the base plate 2, and can be flattened during the movement. faces fit each other.

[0025] see again figure 1 , the automatic food rolling press also includes a control device 5, which is electrically connected...

Embodiment 2

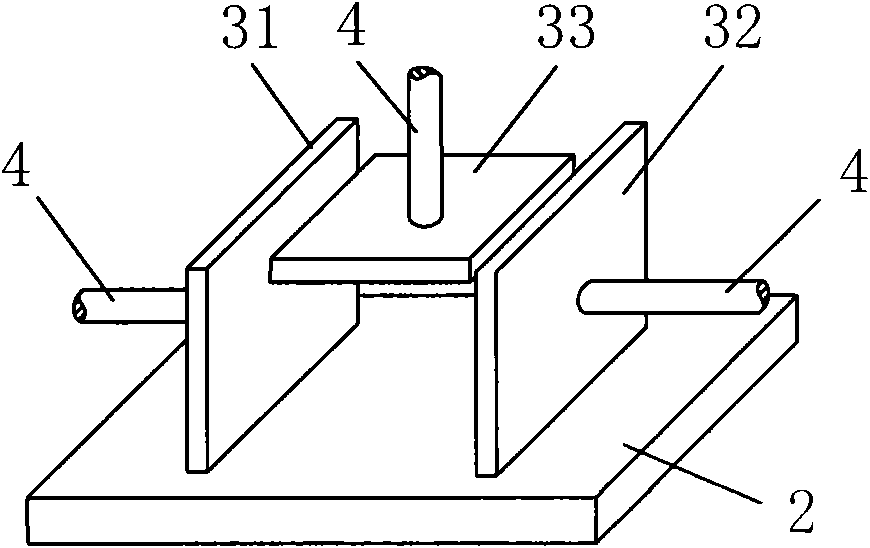

[0028] Such as image 3 As shown, it is a schematic diagram of the internal structure of another embodiment of the automatic food rolling press of the present invention. The structure of this automatic food rolling press is basically similar to that of Embodiment 1, the only difference is that it is also provided with a flat plate 33, which is erected on the top of the base plate 2 and parallel to the plane of the base plate 2, the flat plate The length of the piece 33 is designed to be between 0.2-0.5 times the length of the base plate 2 . In this way, foods such as sushi and rice balls can be further rolled and pressed from the vertical direction to improve their taste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com