Ultrasonic assistant liquid-liquid spray extraction method

An ultrasonic and extraction technology, applied in liquid solution solvent extraction and other directions, can solve the problems of large amount of organic solvent, difficulty in automation, and long liquid-liquid extraction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

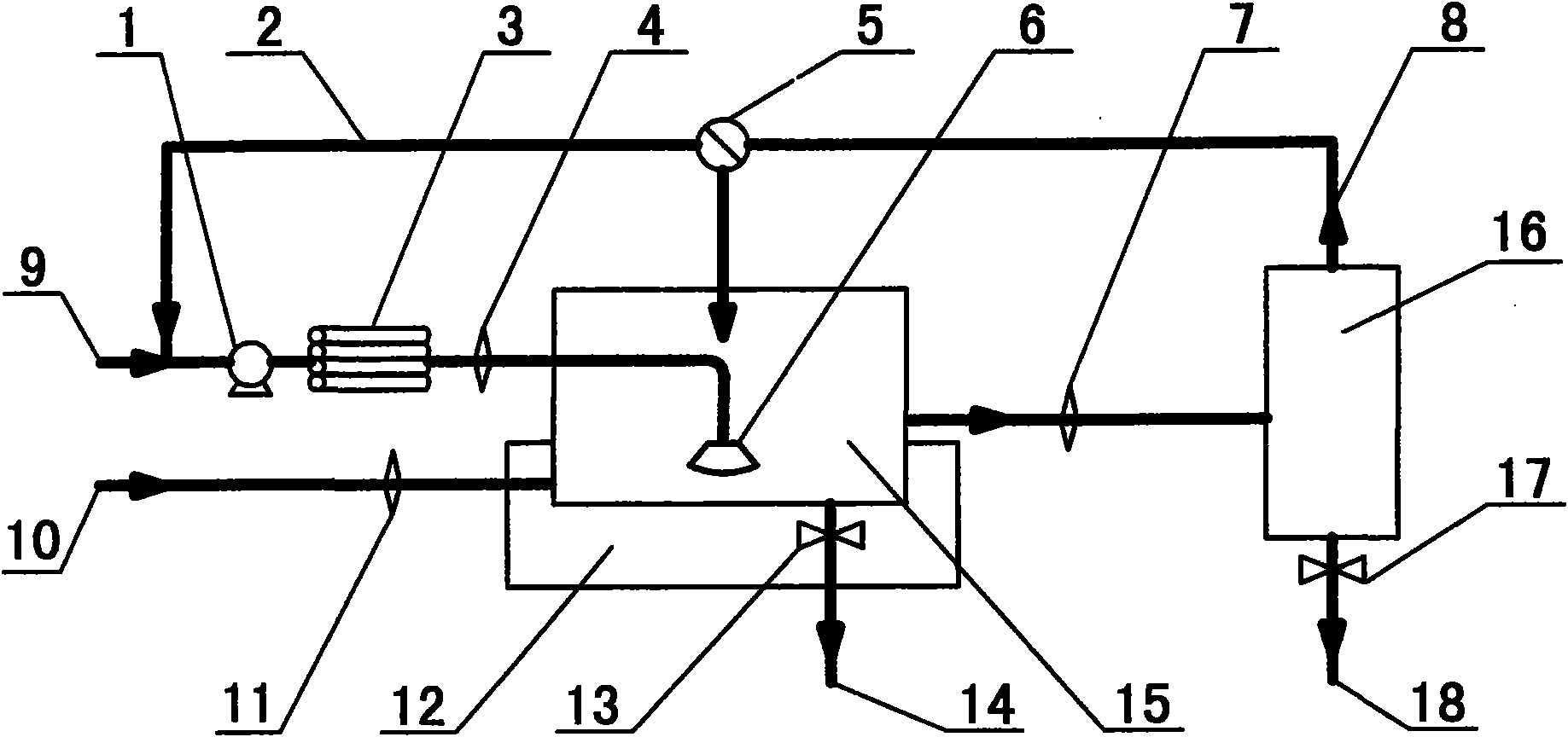

[0011] An ultrasonic-assisted liquid-liquid spray extraction method, using a pump and a nozzle to introduce a liquid sample into an extraction container filled with an organic solvent in the form of atomization through a pressurized method. The pressure is controlled by using a high-pressure bottle or a pressure regulator in a closed system. According to the liquid sample, an appropriate organic solvent is selected and placed in the extractor. At the same time, the extraction container is immersed in the ultrasonic generator. Under the action of ultrasonic waves, the liquid The sample and the organic solvent form a turbulent flow, so that the liquid sample contacts the extraction organic solvent in the form of smaller droplets, and the target compound in the sample is quickly transferred to the organic phase for rapid separation and extraction, and the excess water can be discharged from the water outlet. The organic solvent extract can be taken out from the organic solvent out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com