Photocatalytic water treatment reactor

A technology for water treatment and photocatalysis, which is applied in illumination water/sewage treatment, oxidized water/sewage treatment, energy and wastewater treatment, etc. High efficiency, favorable for photocatalytic reaction, convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the drawings:

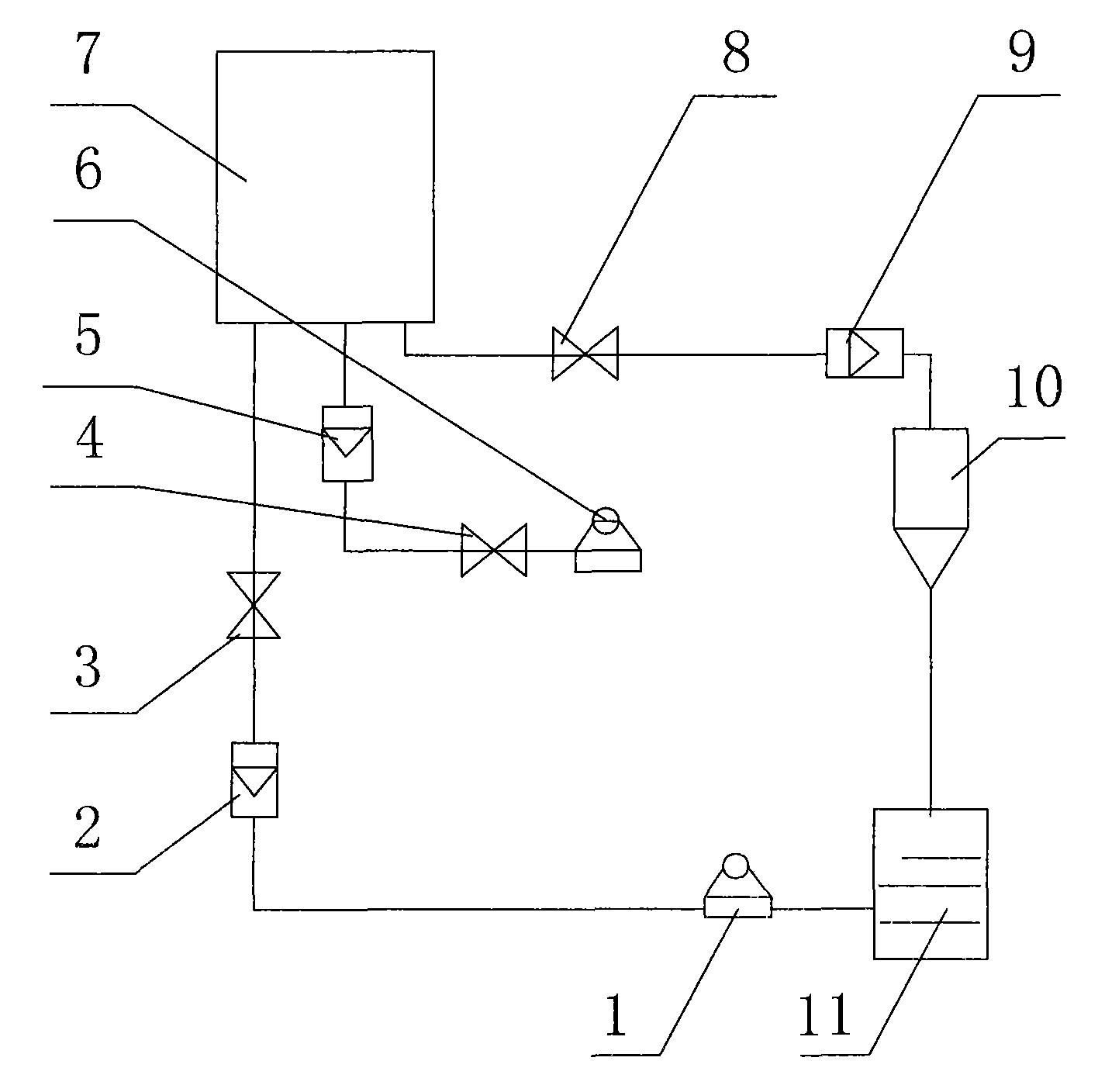

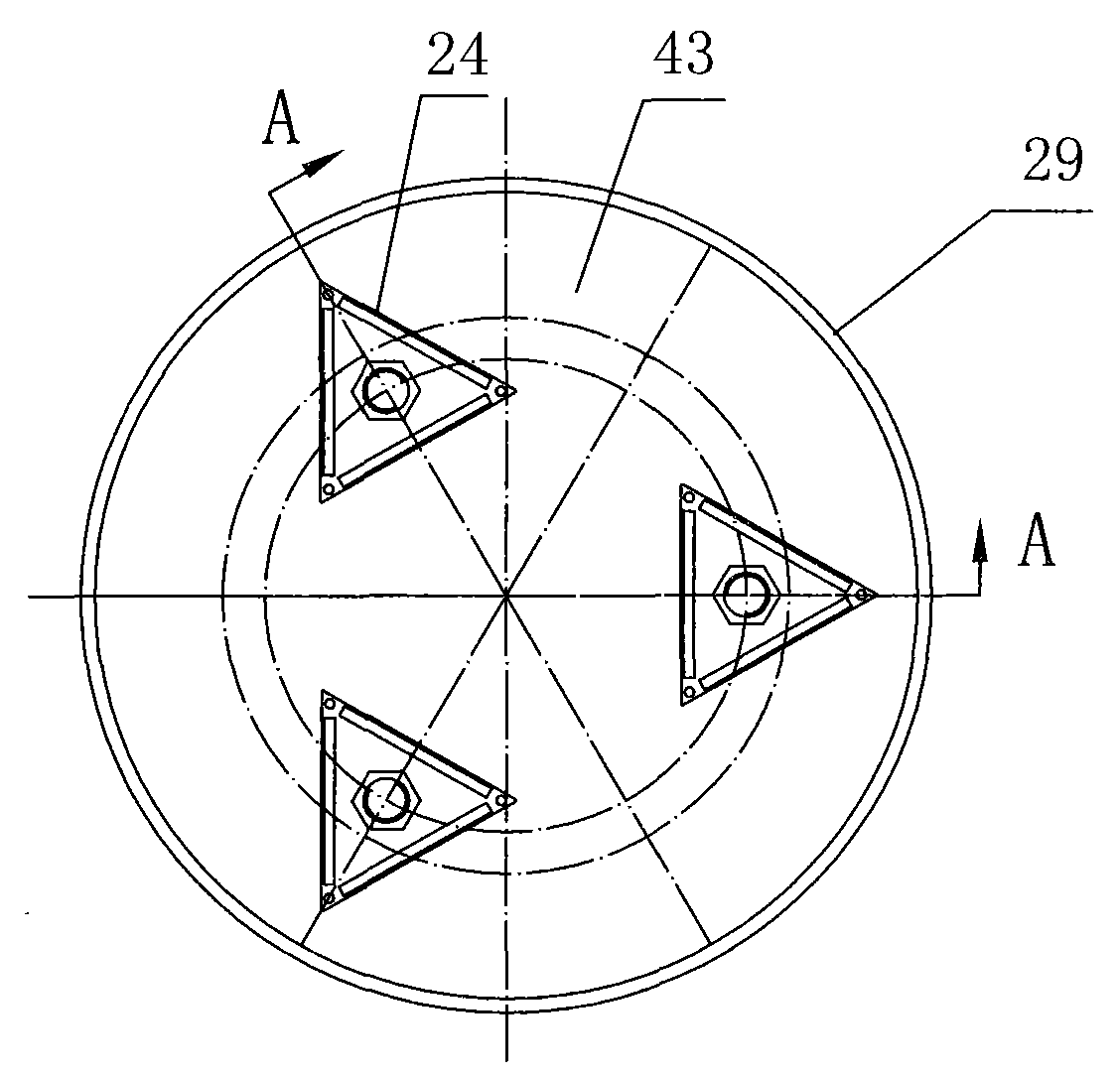

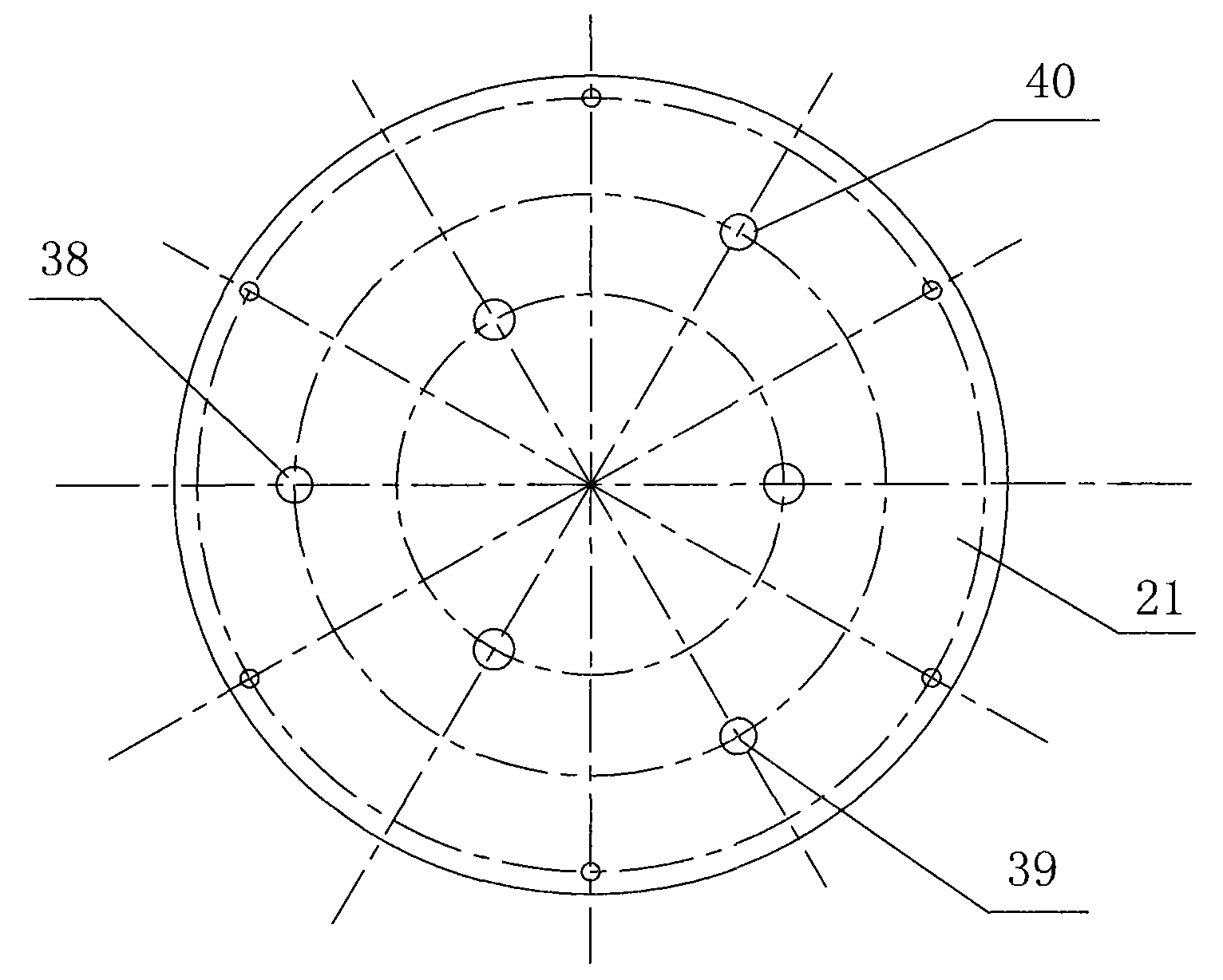

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the photocatalytic water treatment reactor includes a reaction vessel 7, an ultraviolet lamp (or xenon lamp) 27, a catalyst carrier installation device, a stirring device, and an aeration device; the reaction vessel 7 is composed of a bottom plate 21 of the reaction vessel and a cover of the reaction vessel The reaction vessel body 29 is composed of a plate 25 and a reaction vessel body 29. The lower end of the reaction vessel body 29 is fixedly connected to the bottom plate 21 of the reaction vessel (the fixed connection is a sealed connection, and an integrated structure can also be used). The reaction vessel body 29 is surrounded by the bottom plate 21 of the reaction vessel. Into the reaction chamber 43, the reaction vessel body 29 is cylindrical, the material of the reaction vessel body 29 is glass, the bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com