Ferrocement biogas digester

A technology of steel wire mesh cement and biogas digesters, applied in the field of biogas digesters, can solve the problems of poor durability, safety and reliability, difficulty in guaranteeing construction quality, and affecting popularization and application, and achieve short construction period, avoid easy omissions, and technical requirements high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

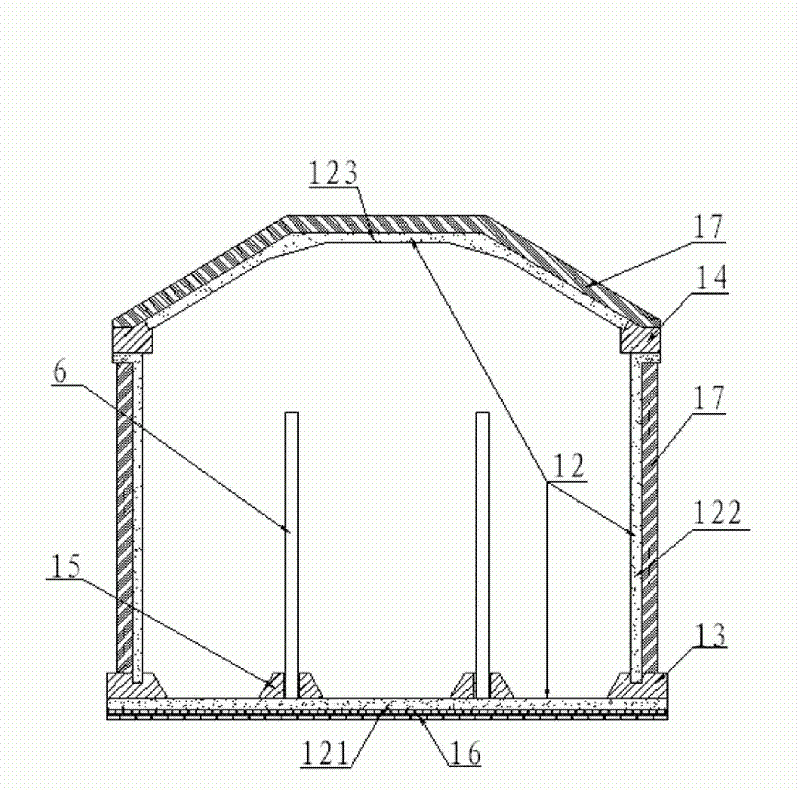

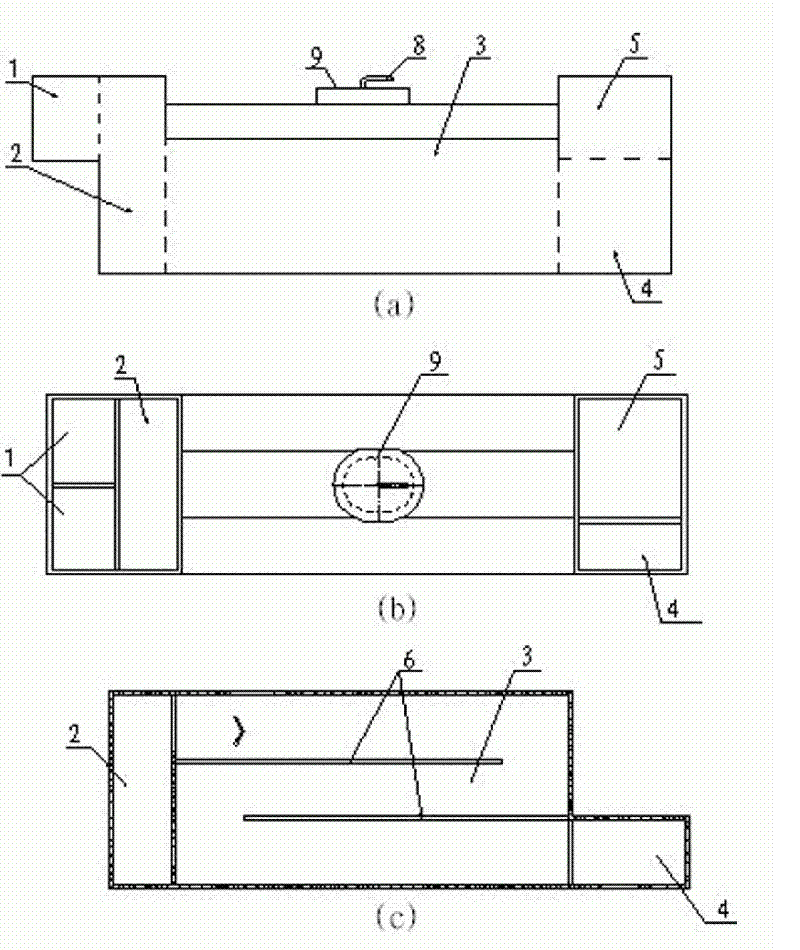

Embodiment 1

[0022] The assembly steps of the present invention are as follows:

[0023] (1) Lay extruded boards with a certain compressive strength at the pre-installation position;

[0024] (2) Use cast-in-place concrete on the extruded plastic board or use prefabricated steel wire mesh cement to assemble on site in sections to form the bottom plate;

[0025] (3) Through the staggered butt joint of the reserved rings on the four sides of the bottom plate and the reserved rings on the side plates, the joints of the bottom plate are interspersed, and the seams are treated with high-grade cement mortar, and the templates are used The reliable fixing and high-frequency vibration ensure the compactness of the mortar at the joint.

[0026] (4) The side panels and side panels are directly staggered through the reserved rings and then interspersed with ribs. The resulting side panel joints are treated with high-grade cement mortar, and through reliable fixation and high-frequency vibration of t...

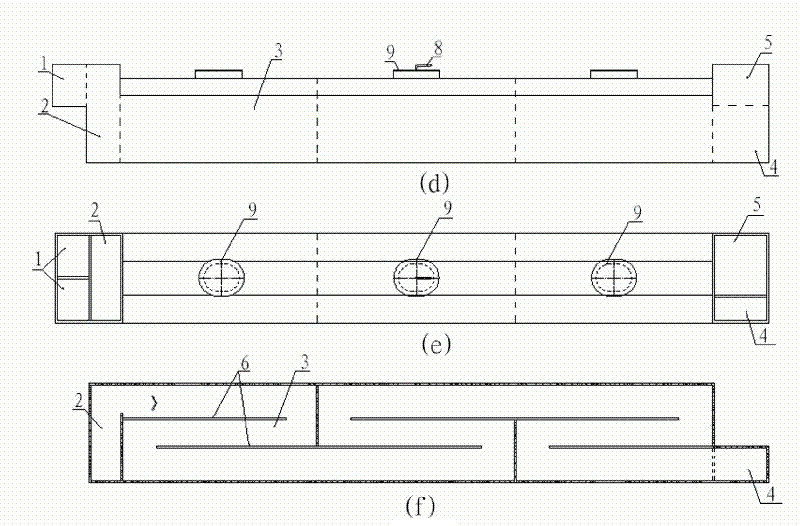

Embodiment 2

[0033] The present invention is combined with the aerobic filter tank as the assembly steps of the community sewage treatment tank as follows:

[0034] (1) Lay extruded boards with a certain compressive strength at the pre-installation position;

[0035] (2) Use cast-in-place concrete on the extruded plastic board or use prefabricated steel wire mesh cement to assemble on site in sections to form the bottom plate;

[0036] (3) Through the staggered butt joint of the reserved rings on the four sides of the bottom plate and the reserved rings on the side plates, the joints of the bottom plate are interspersed, and the seams are treated with high-grade cement mortar, and the templates are used The reliable fixing and high-frequency vibration ensure the compactness of the mortar at the joint.

[0037] (4) The side panels and side panels are directly staggered through the reserved rings and then interspersed with ribs. The resulting side panel joints are treated with high-grade ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com